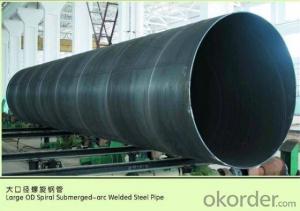

SPIRAL STEEL PIPE 56’‘ 60’‘ LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: What are the safety precautions to follow while working with steel pipes?

- To ensure a safe working environment when dealing with steel pipes, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety goggles, gloves, steel-toed boots, and a hard hat. This will shield you from potential hazards like falling objects, sharp edges, or flying particles. 2. Practice proper lifting methods: Given that steel pipes can be heavy and unwieldy, employ correct lifting techniques like bending your knees and utilizing your leg muscles to avoid straining your back or causing musculoskeletal injuries. 3. Secure the work area: Eliminate any clutter or obstacles in the work area that may present a tripping hazard. Ensure that the pipes are stored and secured adequately to prevent rolling or falling. 4. Exercise caution around sharp edges: Steel pipes often possess sharp edges that can cause cuts or punctures. Handle them with care and consider using protective covers or gloves to prevent injuries. 5. Utilize appropriate tools: Use the correct tools and equipment for cutting, welding, or manipulating steel pipes. Adhere to manufacturer instructions and guidelines to ensure safe usage. 6. Avoid working in confined spaces: Working in cramped areas presents significant risks. If necessary, ensure proper ventilation and adhere to confined space entry protocols to prevent asphyxiation or other hazards. 7. Adhere to proper welding procedures: When welding is involved, follow appropriate welding procedures and guarantee adequate ventilation in the workspace. Employ fire-resistant blankets or screens to protect nearby combustible materials. 8. Be cautious of hot surfaces: Steel pipes can become hot during welding or other processes. Utilize appropriate insulation or heat-resistant gloves to safeguard yourself against burns or heat-related injuries. 9. Establish effective communication: Establish clear channels of communication with colleagues, especially during tasks like lifting or moving heavy objects. Use hand signals or verbal communication to ensure everyone is on the same page and to prevent accidents. 10. Regularly inspect tools and equipment: Before commencing any task, inspect tools, equipment, and scaffolding for damages or defects. Report and replace any faulty equipment to prevent accidents. Always prioritize safety when working with steel pipes. By adhering to these precautions and using common sense, you can guarantee a safe working environment for yourself and your colleagues.

- Q: How are steel pipes insulated to prevent noise transmission?

- Steel pipes are typically insulated using specialized materials that are specifically designed to reduce noise transmission. These insulation materials, such as foam or mineral wool, are wrapped around the steel pipes to create a barrier that absorbs sound waves and prevents them from traveling through the pipes. Additionally, the insulation is often covered with a protective layer, such as aluminum or PVC, to further enhance the soundproofing properties and provide mechanical protection to the insulation.

- Q: Can steel pipes be used for conveying steam?

- Yes, steel pipes can be used for conveying steam. Steel pipes are commonly used in steam systems due to their high strength and durability, as well as their ability to withstand high temperature and pressure conditions. However, it is important to ensure that the steel pipes are properly insulated and the system is adequately designed to prevent any potential issues such as corrosion or thermal expansion.

- Q: How do you transport steel pipes safely?

- Transporting steel pipes safely requires proper planning, equipment, and adherence to safety measures. Here are some guidelines to ensure the safe transportation of steel pipes: 1. Choose appropriate transportation equipment: Use a flatbed trailer or a truck with a flatbed to transport steel pipes. Ensure that the trailer or truck has a strong and secure tie-down system to prevent the pipes from shifting during transit. 2. Secure the pipes: Use nylon or steel straps to secure the steel pipes to the trailer or truck bed. Make sure the straps are tightened properly, evenly distributing the weight of the pipes and preventing any movement or shifting. 3. Protect the pipes: Use pipe chocks or padding materials such as foam or rubber to prevent the pipes from rolling or rubbing against each other during transportation. This helps to minimize potential damage and maintain the integrity of the pipes. 4. Observe weight limits: Ensure that the weight of the steel pipes being transported does not exceed the load capacity of the transportation equipment. Overloading can lead to instability and compromise safety. 5. Follow road safety regulations: Adhere to all local traffic laws and regulations, including speed limits and securing all necessary permits or licenses for oversized loads if required. Additionally, use hazard warning signs or flags when transporting long or oversized steel pipes to alert other road users. 6. Conduct regular inspections: Before starting the journey, inspect the straps, tie-downs, and other securing mechanisms to ensure they are in good condition. Regularly check the load during transit to ensure it remains secure. 7. Plan the route: Choose a route that is suitable for the size and weight of the steel pipes being transported. Avoid roads with low bridges, narrow lanes, or weight restrictions that may pose a risk to the safe transportation of the pipes. 8. Consider weather conditions: Take into account weather conditions, such as strong winds or heavy rain, which can affect the stability of the load. Adjust the transport plan accordingly or delay the journey if necessary. 9. Train and educate drivers: Ensure that the drivers responsible for transporting steel pipes are well-trained and aware of the proper procedures for securing and transporting the load safely. Regularly update them on safety protocols and any changes in regulations. By following these guidelines, you can transport steel pipes safely, minimizing the risk of accidents, damage to the pipes, and ensuring the safety of everyone involved in the transportation process.

- Q: How are steel pipes recycled?

- Steel pipes are recycled through a multi-step process that involves collection, sorting, cleaning, and melting. First, the used steel pipes are gathered from various sources such as construction sites or industrial facilities. Then, they are sorted based on their size, shape, and quality. Next, any contaminants or coatings are removed from the pipes through cleaning and stripping processes. Finally, the cleaned pipes are melted down in a furnace, and the molten steel is formed into new pipes or other steel products. This recycling process reduces the demand for new raw materials and helps conserve energy and resources.

- Q: How do you clean and maintain steel pipes?

- To clean and maintain steel pipes, start by removing any loose dirt or debris using a brush or cloth. Then, use a mild detergent or soap solution to wash the pipes thoroughly. Rinse them with clean water and dry them with a soft cloth to prevent water spots. To maintain them, regularly inspect for signs of corrosion or rust and address any issues promptly. Additionally, apply a protective coating or paint to prevent future rusting.

- Q: What is the difference between hot-dip galvanizing and electroplating of steel pipes?

- Steel pipes can be protected from corrosion using two different methods: hot-dip galvanizing and electroplating. To protect steel pipes using hot-dip galvanizing, they are immersed in a molten bath of zinc. The zinc reacts with the steel to create a strong and uniform coating that effectively prevents corrosion. This method is commonly used for outdoor applications and in harsh environments where the pipes are exposed to water or chemicals. In contrast, electroplating involves depositing a thin layer of metal, usually zinc, onto the surface of the steel pipes using an electric current. The steel pipes act as the cathode, and a zinc anode is placed in a solution containing zinc ions. The electric current causes the zinc ions to react with the steel and form a thin coating. Electroplating is often chosen for indoor applications or when aesthetics are a priority. Hot-dip galvanizing generally provides a thicker and more durable coating compared to electroplating. The hot-dip galvanized coating is several times thicker than the electroplated zinc coating, offering better corrosion protection and a longer lifespan for the pipes. The appearance of the coatings also differs. Hot-dip galvanizing results in a matte gray finish, while electroplating can give a more lustrous and shiny appearance. Cost-wise, hot-dip galvanizing is more cost-effective for larger projects because it can coat multiple pipes simultaneously. On the other hand, electroplating is usually more expensive and time-consuming, especially for larger quantities of steel pipes. Ultimately, the choice between hot-dip galvanizing and electroplating depends on the specific requirements of the project, including the intended application, environment, aesthetics, and budget constraints.

- Q: What are the main components of a steel pipe?

- The main components of a steel pipe include the steel material itself, which is typically made from carbon and alloy steel, as well as various coatings or linings that can be applied to enhance its durability and resistance to corrosion. Additionally, a steel pipe may also have fittings such as flanges or couplings, and may be further reinforced with supports or braces depending on its intended use.

- Q: What is the thickness of steel pipes?

- The thickness of steel pipes can vary depending on the specific application and industry requirements. However, typical steel pipes used in various industries, such as construction and oil and gas, can have thicknesses ranging from a few millimeters to several centimeters.

- Q: What are the different types of steel pipe connections for fire sprinkler systems?

- There are several types of steel pipe connections used in fire sprinkler systems including threaded connections, grooved connections, flanged connections, and welded connections.

Send your message to us

SPIRAL STEEL PIPE 56’‘ 60’‘ LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords