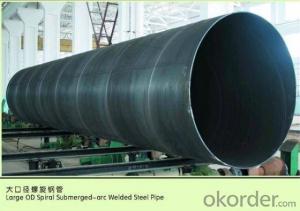

SPIRAL STEEL PIPE 38’‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: How do steel pipes handle high-pressure applications?

- Steel pipes are able to handle high-pressure applications due to their inherent strength and durability. They have a high tensile strength and are resistant to deformation under extreme pressure. Additionally, the seamless construction of steel pipes ensures that there are no weak points or joints that can compromise their ability to handle high pressures.

- Q: How are steel pipes used in the construction of shipbuilding?

- Steel pipes are used in shipbuilding for a variety of purposes, including the construction of the ship's framework, hull, and various onboard systems. These pipes provide structural strength and durability, allowing the ship to withstand the harsh conditions at sea. They are also used for piping systems, such as fuel, water, and ventilation, ensuring the efficient operation of the vessel.

- Q: How are steel pipes protected against soil movement?

- Steel pipes are protected against soil movement through the use of various techniques such as trenching, backfilling, and proper installation of support structures. Additionally, protective measures like the use of casing pipes or concrete encasement can be employed to prevent direct contact with the soil and minimize the impact of soil movement on the steel pipes.

- Q: How are steel pipes measured and specified?

- Steel pipes are measured and specified based on their diameter (nominal pipe size or NPS) and wall thickness (schedule or SCH). The NPS represents the internal diameter of the pipe, while the SCH indicates the thickness of the pipe walls. These measurements are crucial for ensuring proper compatibility and functionality in various applications, such as plumbing, construction, and industrial processes.

- Q: How can galvanized steel tubes be painted on the surface?

- Galvanized parts are nonferrous metals, ferrous metals are black, all metal adhesion is poor;

- Q: What are the different types of steel pipe couplings?

- There are several types of steel pipe couplings, including threaded couplings, socket weld couplings, butt weld couplings, flanged couplings, and compression couplings.

- Q: Can steel pipes be used for conveying oil?

- Yes, steel pipes can be used for conveying oil. Steel pipes are commonly used in the oil and gas industry for transporting oil due to their strength, durability, and resistance to corrosion. The high strength of steel pipes allows them to withstand the high pressure and temperature conditions that are often associated with oil transportation. Additionally, steel pipes are less prone to leakage and damage compared to other materials, making them a reliable choice for conveying oil over long distances. Moreover, the smooth interior surface of steel pipes helps to minimize friction and enhance the flow of oil. Overall, steel pipes are a preferred option for oil transportation due to their superior mechanical properties and long-term performance.

- Q: What do you mean by "SC" in welded pipe SC200? What's the diameter of 200?

- Including galvanized steel pipe, but galvanized steel pipe is generally used for plumbing professional, electrical professional generally only civil air defense or high anti-corrosion requirements of the region;

- Q: How do you repair a damaged steel pipe?

- To repair a damaged steel pipe, you can follow a few steps. First, identify the extent of the damage, such as cracks or holes. Next, clean the damaged area using a wire brush or sandpaper to remove any rust, debris, or old paint. Then, apply a suitable epoxy or sealing compound to seal the crack or hole. For larger damages, welding or brazing may be necessary. Finally, ensure the repaired area is dry and properly cured before testing the pipe for leaks or further issues.

- Q: What is the maximum temperature that steel pipes can handle?

- The maximum temperature that steel pipes can handle depends on the specific grade of steel being used. However, most common steel pipes can withstand temperatures up to around 1000 degrees Celsius (1832 degrees Fahrenheit) without significant structural damage.

Send your message to us

SPIRAL STEEL PIPE 38’‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords