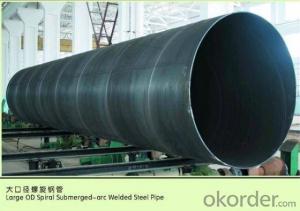

SPIRAL STEEL PIPE 46‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation | |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050< span=""> | <0.045< span=""> | <0.030< span=""> | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05< span=""> | <0.045< span=""> | <0.030< span=""> | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045< span=""> | <0.045< span=""> | <0.030< span=""> | >235 | 375-500 | 24-26 |

Q345 | <0.20< span=""> | 1.0-1.6 | <0.040< span=""> | <0.040< span=""> | <0.55< span=""> | >345 | 470-630 | 21-22 |

- Q: What's the difference between straight steel pipe and seamless steel pipe?

- The welded pipe is made of rolled steel plates, and small ones are straight welded, and big ones are spiral welded. Because the welded pipe has weld, the mechanical performance of weld is poor, so its applicable range is limited, but its price is cheap. Significant difference is that there are welded pipe, seamless steel pipe is not, of course, the welded pipe treatment of good, layman do not see the difference.

- Q: Are steel pipes suitable for use in chemical plants?

- Yes, steel pipes are generally suitable for use in chemical plants. They are known for their high strength, durability, and resistance to corrosion, making them well-suited for transporting various chemicals and fluids. Additionally, steel pipes can withstand high temperatures and pressures, making them a reliable choice for the demanding conditions often found in chemical plants.

- Q: How are steel pipes protected against UV radiation?

- Steel pipes are typically protected against UV radiation through the application of coatings or paints that contain UV inhibitors. These coatings act as a barrier between the steel surface and the harmful UV rays, preventing damage and degradation of the pipes over time. Additionally, some steel pipes may be treated with zinc or other metals, which offer inherent UV protection and enhance the overall durability of the pipes.

- Q: Can steel pipes be used for transportation of hazardous materials?

- The transportation of hazardous materials can indeed utilize steel pipes. Steel is renowned for its robustness, longevity, and resistance to rust, which renders it suitable for the management and conveyance of various perilous substances. This encompasses combustible liquids, noxious chemicals, and other hazardous materials. Steel pipes, employed for the transportation of hazardous materials, are frequently custom-designed and fabricated to comply with strict safety regulations and industry standards. They are typically forged from top-notch steel alloys and subjected to stringent tests to guarantee their integrity and resistance to leaks or ruptures. Additionally, steel pipes can be manufactured with supplementary protective coatings or linings to furnish an extra layer of security and avert any potential reactions between the hazardous substance and the steel. These coatings can also aid in reducing the risk of corrosion and prolonging the lifespan of the pipes. In summary, steel pipes have an established record in the transportation of hazardous materials due to their inherent strength, durability, and ability to withstand the challenging conditions frequently encountered during transportation. Nonetheless, it is imperative to adhere to proper protocols for handling, storage, and transportation to ensure the safety of both the transported materials and the individuals involved in the process.

- Q: How are steel pipes used in the manufacturing of food and beverage processing plants?

- Steel pipes are commonly used in food and beverage processing plants for various purposes such as transporting liquids, gases, and steam. They are used to create a network of pipelines that facilitate the movement of raw materials, ingredients, and finished products throughout the manufacturing process. Steel pipes are chosen for their durability, corrosion resistance, and ability to withstand high pressure and temperature conditions, ensuring the safety and efficiency of food and beverage production.

- Q: Can steel pipes be used for sewage systems?

- Yes, steel pipes can be used for sewage systems. Steel pipes are commonly used in sewage systems due to their durability, strength, and resistance to corrosion. They are particularly suitable for high-pressure applications and can withstand the harsh conditions often found in sewage systems. Additionally, steel pipes are relatively easy to install and maintain, making them a popular choice for sewage infrastructure projects.

- Q: Can steel pipes be used in the automotive industry?

- Yes, steel pipes can be used in the automotive industry. They are commonly used for various applications such as exhaust systems, fuel lines, and structural components due to their strength, durability, and resistance to heat and corrosion.

- Q: How can seamless steel tubes be produced?

- After extrusion to remove pipe sizing. The sizing machine passes through the cone bit and rotates into the steel embryo at high speed to form a steel tube. The inner diameter of the steel pipe is determined by the outside diameter and length of the sizing machine. When the steel tube is fixed, it enters the cooling tower and is cooled by spraying water. The steel tube is straightened after cooling. After straightening, the steel pipe is sent to the metal flaw detector (or water pressure experiment) by the conveyor belt for internal inspection. If there are cracks in the steel pipe, bubbles and other problems will be detected. Steel pipe quality inspection, but also through strict manual selection. After the quality inspection of the steel pipe, spray with the paint on the number, specifications, production batch number and so on. The crane is hoisted into the warehouse.

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are commonly used in HVAC systems for transporting hot or cold water, as well as other fluids like refrigerants and condensate. They are durable, resistant to corrosion, and can withstand high pressure, making them ideal for carrying fluids throughout the system. Steel pipes are typically used for water supply lines, steam distribution, and hydronic heating and cooling systems in HVAC installations.

- Q: Can steel pipes be used for conveying liquids and gases?

- Yes, steel pipes can be used for conveying both liquids and gases. Steel pipes are commonly used in various industries, including oil and gas, water supply, plumbing, and industrial processes, due to their strength, durability, and resistance to corrosion. They are capable of withstanding high pressure and temperature, making them suitable for transporting a wide range of liquids and gases such as water, oil, natural gas, steam, and chemicals. Additionally, steel pipes can be welded or threaded together, allowing for easy installation and maintenance.

Send your message to us

SPIRAL STEEL PIPE 46‘‘ ASTM API LARGE DIAMETER PIPE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords