Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

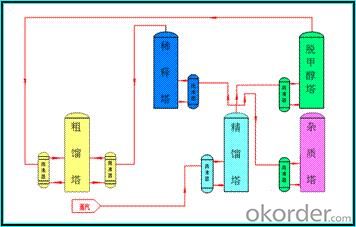

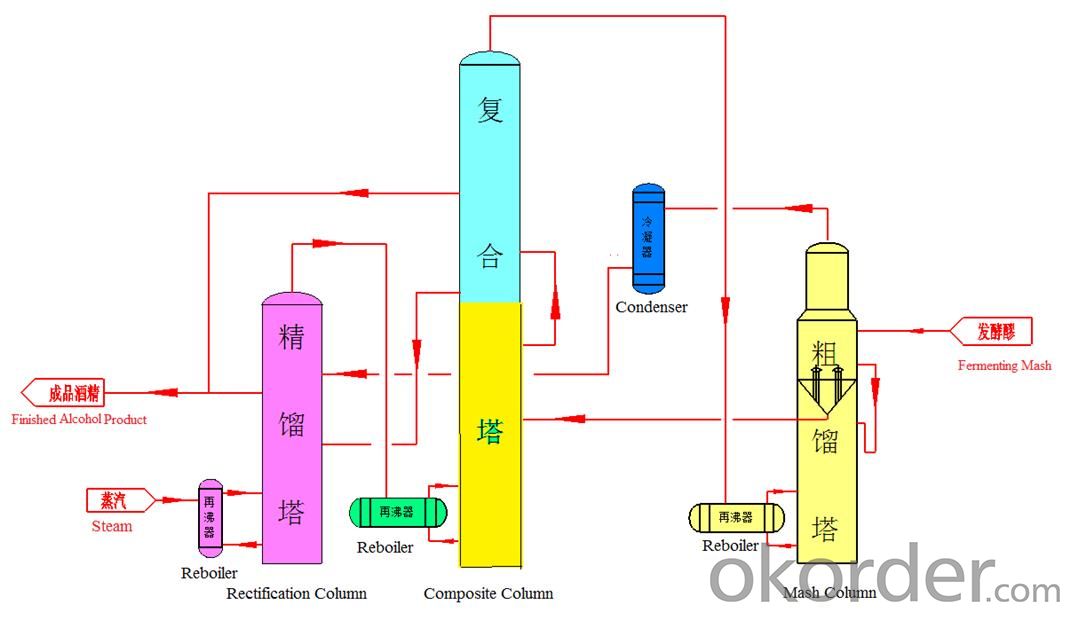

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: We bought a home that has 2 units - one for the main floor and basement and one that covers the upstairs.The previous owners updated the system in 2004 with a heatpump upstairs. I HATE heatpumps. I want tto just leave the heat pump in place (use it for AC only), but add on a nat. gas system. It has to cover about 1200 sq. feet. The gas line has to be run from the basement to the attic. About how much would that run?

- It's very difficult to give you an estimate without seeing your house. You should try to call your local contractors about this. It's not a small job so you may get a free estimates. Get at least 3-4 bids from different contractors!

- Q: I have to put these in correct order, and I can't seem to find it in my book or a diagram.A. Steam produced by boiling water causes the blades of a turbine to rotate.B. A neutron bombards a uranium-235 isotopeC. Thermal energy released by the reaction is adder to the water.D. Electricity from the generator is carried to the community through wires.E. A uranium-235 atom splits, producing two atoms with smaller nuclei, three neutrons, and thermal energy.F. The mechanical energy of the rotating turbine blades is transferred to an electric generator.G. Superheated water passes through a heat exchanger, where the thermal energy released boils a separate system of water to produce steam.

- B. A neutron bombards a uranium-235 isotope E. A uranium-235 atom splits, producing two atoms with smaller nuclei, three neutrons, and thermal energy. C. Thermal energy released by the reaction is adder to the water. G. Superheated water passes through a heat exchanger, where the thermal energy released boils a separate system of water to produce steam. [Note, this is only true for pressurized water reactors, not boiling water reactors] A. Steam produced by boiling water causes the blades of a turbine to rotate. F. The mechanical energy of the rotating turbine blades is transferred to an electric generator. D. Electricity from the generator is carried to the community through wires.

- Q: A well in insulated heat exchanger is used to heat 4.5 kg/s of water from 20 degrees C to 75 degrees C at a constant pressure. Heat is supplied by 10 kg/s of hot oil (Cp=2.3 kJ/kg K) that enters at 170 degrees C. Oil pressure also constant. No boiling occurs. *a.) What is the heat transfer rate to the water? *b.) What is the rate of entropy production, Sgen? *c.) What is the primary source of irreversibility? d.) sketch and label a T-s diagram for both oil and water. e.) What is the rate of irreversibility of the device, I?

- a) The heat transfer rate to the water = 3,535,844BTU/hr/3413 = 1036KW The outlet temperature of the water = 75 DegC (167 DegF) The outlet temperature of the oil = 127 DegC (260.8DegF)

- Q: and where can i find the index for current year

- Which index do you want. You can find one in the Oil and Gas Journal and another in Chemical Engineering magazine. Both will be slightly behind current time because they are historical in nature and not predictive.

- Q: Central gas heat. Sequence is: (1) t-stat asks for heat, (2) exhaust blower kicks in and makes exhaust pressure switch (3) glow plugs fire (4) gas flow starts (5) flames, heat exchanger heats up (6) fan limit kicks in and heats house.This works fine ... sometimes. It's easy to find a broken component, harder to find a temperamental one. Where would you start?

- if you have only 1 setting on your heater, its probably the heater switch on the dash. also flush out the cooling system and change the thermostat.

- Q: I have a 30x40 woodworking shop, I installed a small cast iron stove, that I burn scrape wood in, on days when the temp. is down in the teens it takes for ever to heat the shop to a temp. that I can work,I wondered if a heat exchanger would be worth while.

- Heat transfers through the metal surfaces of the stove and as it travels up the flue (vent) pipe. Consider venting through lots of vent pipe that has a lot of surface area to transfer the heat into the room. The vent pipe can be the heat exchanger you speak of. If the heat were to be vented out in a direct straight shot, that would let the heat escape before transferring to the room. If it winds through lots of vent that is in the room, that will allow more transfer to the room.

- Q: and shall it be vertical/horizontal? where shall I put alcohol in shell or tube? I do have a 110 C temp difference do I have to use a floating head?

- I don't agree that the cooling or heating medium is on the shell side. Typically these are on the shell side. That is specially true when boiling or evaporating a liquid. You want to have an extra large shell to permit the separation of the vapor from the boiling liquid. In the case of a cooling medium (usually water) you want to be able to clean the heat transfer area and that is easier to do if the cooling medium is on the tube side. As to the floating head. Most of the time the designer would rather build a U-tube bundle if possible in a kettle type design. That eliminates problems with a floating head that can leak and have other problems. This would be a BKU TEMA configuration. It would also be a horizontal design because that best for easy access for maintenance.

- Q: AS PER TEMA/ASME.IF HAVING ANY LINK, PDF/OTHER FILE, ANY LITERATURE, PLZ. FORWARD ME.

- Don't type in all caps please, it's just rude. It really doesn't make people want to answer your question more. Try writing an email to an employer in all caps to show your enthusiasm and see what happens

- Q: Chemical Engineering Calculations withour reactions. Water at 180F is pumped at a rate of 100ft^3 /hr through a heat exchanger to reduce the water temperature to 100F. Finda the rate at which heat is removed from the water in the heat exchanger Please help me step by step process

- James' method is correct. However: (i) water at 180F weighs only 60.6 lbs/ft3 (ii) the flow is 100 ft^3 per hour. The heat removal rate is approximately 485,000 BTU/hour

- Q: Are there any differences is performance letting the hot fluid flow thru the inner pipe and the cold fluid thru the annulus and vice versa??

- they're an economic determination for small exchangers that would desire to easily require some accepted tubes. they're additionally a sturdy determination for smaller intense tension applications. the alternative is often one in keeping with economics. there is not any rule that determines the determination technique.

Send your message to us

Spiral plate heat exchanger(Detachable)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords