Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. The spiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

公称换热面积m2 | 通道间距m2 | 计算换热面积m2 | 流速1m/sec时处理量m3/h | 接管公称直径dg | 型 号 | 质 量(kg) I6T型 II6T型 | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

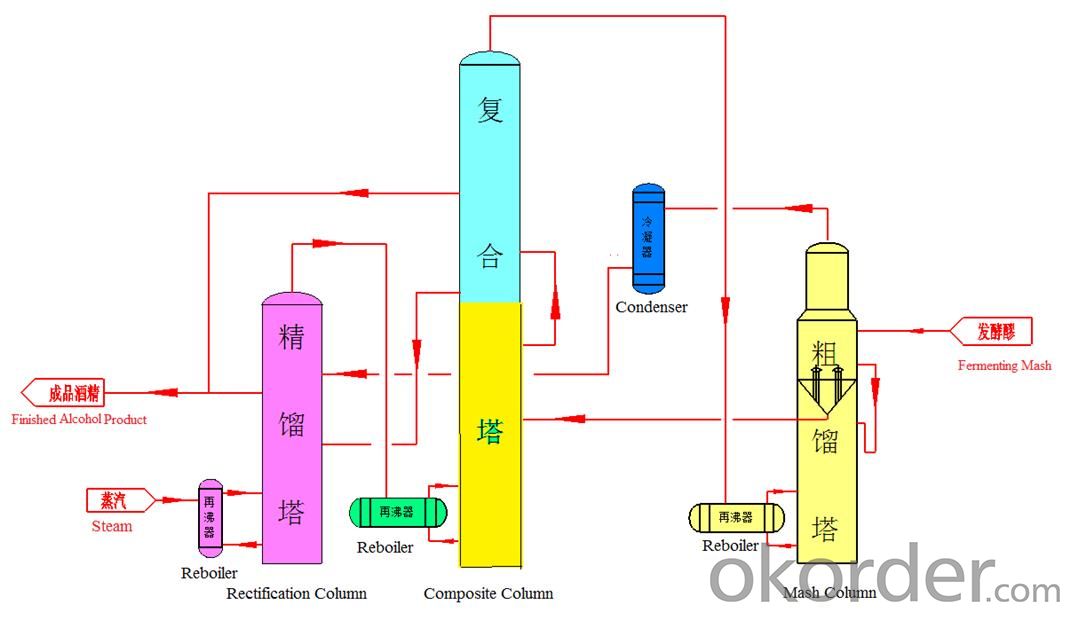

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety

Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: We are looking into purchasing a home with a Tempstar NUGM125EKA1 furnace. The home inspector said that this model of furnace is known to have problems with the heat exchanger cracking. If this is true, has the replacement exchanger been re-engineered to prevent this problem? Is there any way to tell if the previous owner had the exchanger upgraded already? I can't ask the previous owner because he is unavailable. What would an estimated heat exchanger replacement cost? Is this something that may happen or something that will happen? If hasnt happened yet does that mean this heat exchanger is a quot;goodquot; one and it wont happen? Thanks in advance.

- You did not provide the SN# so here is my answer to you. If your unit falls within the range. . Heil and Tempstar Furnace Eyelet Failures Models NUGM, NTGM, NDGM, NCGM with date codes of L9421 through L9723. These furnaces were subject to premature heat exchanger failure and were thus the subject of a service bulletin due to eyelet failures. If you own one of these furnaces, we suggest that you speak to your heating contractor for possible repairs or replacement of the system. I would have the exchanger checked for cracks or holes where the exchanger is pinched together with rings. Its not worth replacing if you as me, you would be better off with a new furnace. I would also advise you to install a carbon monoxide detector. The had issues and to be honest I cant remember if the revised heat exchanger corrected this problem or not. The statement above are from an old svc record, so just based on that I would junk it if it has problems there were nothing but money pits

- Q: I have an old house and vapors are coming up registers! New heat/air cond. system.I have had vents cleaned twice. same thing happened with old furnace! Is it worth the cost to replace vent system when we may sell home in a year or so! And they may tear it down for the property? Is it really expensive! Thank you everyone!

- Sorry I am of no help but my goodness it doesn't seem like that long since you had problems with that furnace. Hope you get some good advice.

- Q: a. nonshivering thermogenesisb. storage of brown fatc. shivering and vasoconstrictiond. thick layers of blubber and countercurrent heat exchangerse. all of the above

- (c) Shivering is the body's response to low temperatures and assists in homeostasis.

- Q: when you want water to boiled is it best to start with cold water to heat quicker?

- This doesnt relatively make you warmer, besides the undeniable fact that it makes your ideas think of you're. you purely say Ahh this water is so heat! It feels sturdy! Lol. whilst i pass surfing interior the morning, that what I do. Then my legs get numb, and you dont sense something anymore. and then, in case you concentration on something besdieds how chilly the water is, it might desire to help. per danger if your reallly reallllyyy warm previously, the water will sense sturdy!! Sorry this wasnt lots help! wish you win, you something (o:

- Q: Please tell me about the latest types of heat exchangers and any available online references?

- So far as materials go, the use of plastics in the exchangers rather than metal has been one of the latest advances. If you are asking about gases, work is being done to replace HFC's. One refrigerant that is being actively developed is CO2 (carbon dioxide). Now, if you were asking about novel or new-age developments, there is on-going work with thermotunneling and magnetics. You can go to the Department of Energy web site and eventually find more information.

- Q: My gas company red-tagged my furnace due to carbon monoxide leaking, because of a failed heat exchanger. Should I get the heat exchanger replaced for $1000 (parts and labor) or just get a new furnace for about $3500?The furnace is a 1996 Tempstar 90% efficiency model.

- go to an ultra efficient variable speed system w/a brand name like carrier or Bryant or lennox, add a air source heat pump. 96-97% furnace a 18 seer a/c to make a terrific dual fuel system, and laugh at those opec countrys let em eat their oil and gas..

- Q: In a solar heating system the energy gained is during the day is stored in large tanks for use at night.Why is neither pure water or pure ethylene glycol used? O_O please help me.

- Solar thermal systems use a blend of a glycol and water to take advantage of favorable features. Glycol is included because it lowers the freezing temperature of the blend, to prevent formation of ice. Water is included because of its excellent thermal conductivity and specific heat capacity, highest among just about all fluids. The glycol is more often propylene glycol than ethylene glycol. It is surprising, but true, what the difference of two hydrogens and a carbon make in terms of toxicity...but propolyne glycol is relatively non-toxic, unlike its ethylene glycol counterpart. So, if the fluid blend is to interact with domestic use water on opposite streams of the heat exchanger, it is best to choose propolyene glycol in order not to make it a poison. If it isn't, and only will be used for heating, then ethylene glycol can be used.

- Q: We are in a brand new house with a brand new furnace. It is set for 69* during the day quot;wakequot; hours and 66* during the night quot;awayquot; hours. The fan is set to auto, and the temperature is set to heat, but it never shuts off. It ran for 4 hours yesterday and the temperature never went above 69* and it didn't turn off for even a few minutes. It's 37* at night, so we still need the heat, but our electric meter is running up because the furnace never shuts off, and it's really a pain to have to manually turn it on and off, plus that doesn't work at night when we're sleeping.Does anyone have any suggestions, or is that common in new houses with new furnaces? (by new I mean new construction, not just new to us)Thank you!

- A furnace uses Gas to heat and the fan doesn't come on (in Auto) until the heat exchanger heats up and will go off after the heat shuts off and the fan runs to cool the heat exchanger. If the fan is running all the time, then your fan may be set to on or has a sticking relay. That doesn't necessarily sound like what you are describing, Sounds like you might have a heat pump. If that is the case then you could have some refrigerant problems. ------------------Since it's a heat pump, it's probably too cold outside for it to work efficiently. It should have electric heat strips to compensate for this. It might still have refrigerant problems. Is the outside part frozen up or look white? maybe the defroster isn't working correctly. Best to call a local tech in this situation

- Q: My English is not very good as I'm not a native speaker and I have to write a description of a product. Which version sounds best?(this is about a sauna stove)Parameters: heat output (KW)Possibility to connect a heat exchanger to heat water for sauna use / Offers an option of installing a heat exchanger for heating water for sauna use / With an option of connecting a heat exchanger to heat water for sauna use.

- It is possible to connect a heat exchanger to the sauna stove to heat water

- Q: why purge heat exchangers?

- In many heat-exchange systems, solids will fall out of solution due to the change in temperature. The solids can adhere to the piping walls and inside valves (etc.) and, in doing so, can dramatically change the flow-rates of fluid through the exchanger. Overall, this usually manifests as either a non-working or highly inefficient system. We used to call the cleaning (or purging) of the piping de-scale - because the junk that built up inside would come out as little flakes that looked like fish scales.

Send your message to us

Spiral plate heat exchanger(Non-Detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords