Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Re-boiler is ahigh-efficient heat exchanging equipment used in alcohol, solvent, foodferment, pharmaceutical, petrochemical, refrigeration, organic chemistry, metallurgicalindustry, suitable for convection heat transfer of liquidtoliquid,gas to gas,gas to liquid. Re-boiler is made of carbon steel and stainless steel.

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

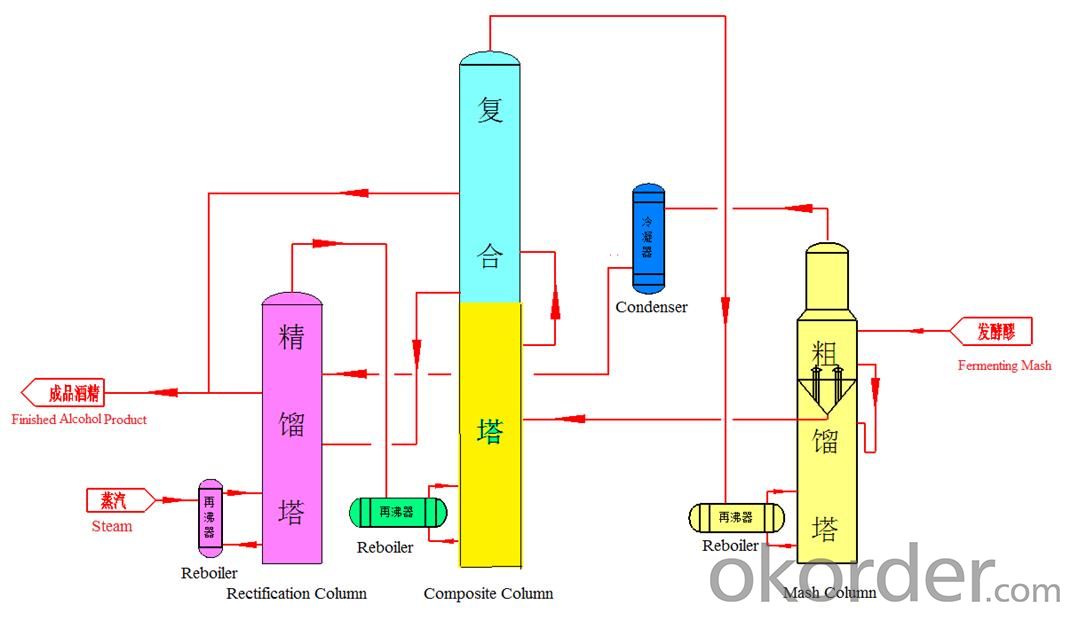

Double-Mash-Column Three-Effect DistillationProcess

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

Weown advanced machining equipment and product testing equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC

Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: I installed a wood boiler and put the heat exchanger in the plenum and was wondering if i should increase the blower speed, it seems the heat exchanger is restricting some air flow to the vents.

- Blower-speed is a calculation based on the CFM needed against the exchange temperature involved. If the exchanger gets very hot, you will need to speed up the fan to remove the excess heat. But you should do this by calculation rather than by guess. Further to this, the amount of CFM your system can pass will be based on the supply and return duct sizes - so there will be top limits beyond which there is no benefit. Also which can be calculated.

- Q: It's a central heating unit, individual to our apartment. We have the thermostat set at 71, heat, fan - auto. Within 1 hour the fan had run 3 cycles 15 min each, and the heat only once for about 10 minutes. Our maintenance staff says it's working properly, but our last bill was through the roof and we now have to manually turn on/off the heat.

- no it is not.

- Q: but i think that it's related to heat exchangers. So, how does the Steam Power Plant work? And how is it analyzed?

- Thanks for the laughs. I woke up crying and I really needed that. I laughed until my stomach. I will make sure my friends get a copy of this (If I can find a friend today?) I always like the ones about the little children because I am not sure these are jokes. Out of the mouths of babes they could be true. This one certainly deserves a star. It nice to get one that is not a complaint! Have a wonderful day and thanks for the laugh!

- Q: If so, please email me your resume. The job location is in West Chester PA.

- use the Boyle-Mariotte's law

- Q: Process water with a specific heat capacity of 4.182 KJ Kg-1 K -1 flows at a rate of 0.050 Kg s-1 through a heat exchanger where its temperature is increased from 16C to 85C. Heat is supplied by exhaust gases (mean specific heat capacity of 1.075 KJ Kg-1 K-1) which enter the heat exchanger at a temperature of 420C. If the mass flowrate of the exhaust gases is 0.044 kg s-1, determine their outlet temperature.

- Energy flow = (specific heat) X (mass flow rate) X (delta T) Calculate the energy flow to the cooling water. Use that value for energy flow to calculate delta T for the exhaust gas using the equation above.

- Q: we were given a hot tub but the motor and i think pump but we are not sure, do not work. We have no idea about hot tubs. All the model info and quot;stuffquot; has been worn off the actual piece with info.Here is the info we have from the pieces left.HEATFLO HEAT TRANSFER SYSTEM, ULTRA JET...can anyone help us and tell us what we need to get this going?a motor and pump?we do not have a lot of money so were looking for a used one...any assistance would be appreciated!thank you

- Hire a hot tub mechanic to help you. You state you don't have a lot of money. So don't waste what you have by replacing parts you don't need in an attempt to fix something that may not be broke. And yahoo is full of silly people who have no clue what they are talking about. Taking advise seen on here is rather silly.

- Q: Is it possible to use an air conditioner to heat a pool? It seems like I might be able to use a liquid heat exchanger to cool the hot part of the air conditioning cycle using swimming pool water. Can someone give me an overview of how to build a system like the following myself

- How do you expect this system to work? Why would you heat your pool in the summer when it is already hot outside? The sun naturally heats your pool. That is when you run you air conditioner. Wouldn't you want to heat your pool in the winter when it is cold outside? You're not running your air conditioner at that time.... That's probably why no one else is doing it.

- Q: I have a gas heat unit.. the piolt light is lit and the heat is turned on yet i am gettin cold air out of my vents.. sometimes it cold air then sometimes it works just fine for a day or 2 then will blow out cold air/

- I'm a roofer by trade by sounds like a thermostat problem. the one at dads rental propriety used to do that and we found that the fan was running all the time. you should call HVAC certified tech. to be safe sir. plugged (pilot) orifice is a common problem (gas line)

- Q: show the effect of the mass flow rate on the heat flow and the transfer coefficient?

- sorry, i only speak English.

- Q: If any body knows about a solar panel which can perform both the operation in a single panel i.e heating up the water as well as charging the batteries for electricity in a single panel. Please describe me about that and let me know where to look for it.

- That is a million dollar idea if it isn't invented yet

Send your message to us

Re-boiler

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords