The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The spiralplate heat exchanger is a high-efficient heat exchanging equipment used inalcohol, solvent, food ferment, pharmaceutical, petrochemical, refrigeration,organic chemistry, metallurgical industry, suitable for convection heattransfer of liquidtoliquid,gas to gas, gas to liquid.

The spiralplate heat exchanger comprises detachable and nondetachable exchanger. Thespiral plate heat exchanger is made of carbon steel and stainless steel.

The argument list of carbon steel spiral plate heat exchanger

Nominal heat transfer areaNominal heat transfer areaNominal heat transfer area | Channel Spacing | Calculate heat transfer area | handling capacity(flow rate: 1m/sec) | Nozzle nominal diameter | Model | I6T quality II6T quality | |

40 | 10 | 40.9 | 20.9 | 80 | I6.II6T40-0.6/1200-10 | 1730 | 2772 |

14 | 42.3 | 39.3 | 100 | I6.II6T40-0.8/1200-14 | 1843 | 2835 | |

18 | 44.9 | 63.5 | 125 | I6.II6T40-1.0/1200-18 | 2069 | 3061 | |

50 | 10 | 50.2 | 35.3 | 100 | I6.II6T50-1.0/1000-10 | 2334 | 3070 |

14 | 53.2 | 49.4 | 125 | I6.II6T40-1.0/1200-14 | 2408 | 3400 | |

18 | 54.0 | 76.3 | 125 | I6.II6T40-1.2/1200-18 | 2430 | 3422 | |

60 | 10 | 60.8 | 20.9 | 80 | I6.II6T60-0.6/1400-10 | 2673 | 4231 |

14 | 60.7 | 39.3 | 100 | I6.II6T60-0.8/1400-14 | 2750 | 4308 | |

18 | 61.6 | 63.5 | 125 | I6.II6T60-1.0/1400-18 | 3097 | 4655 | |

80 | 10 | 81.4 | 28.1 | 100 | I6.II6T60-1.0/1400-10 | 3365 | 4923 |

14 | 80.6 | 39.3 | 100 | I6.II6T80-0.8/1600-14 | 3445 | 5796 | |

18 | 82.0 | 63.5 | 125 | I6.II6T80-1.0/1600-18 | 3682 | 6033 | |

100 | 10 | 101.4 | 28.1 | 100 | I6.II6T100-1.0/1600-10 | 4250 | 6601 |

14 | 101.8 | 49.4 | 125 | I6.II6T100-1.0/1600-14 | 4390 | 6741 | |

18 | 108.2 | 76.3 | 125 | I6.II6T100-1.2/1600-18 | 4460 | 6811 | |

120 | 14 | 121.5 | 42.5 | 125 | I6.II6T120-1.2/1700-14 | 5130 | 7718 |

18 | 120.0 | 59.4 | 125 | I6.II6T120-1.2/1800-18 | 5250 | 7960 | |

130 | 14 | 130.5 | 32.5 | 125 | I6.II6T130-1.2/1800-14 | 5570 | 8280 |

18 | 131.0 | 49.4 | 125 | I6.II6T130-1.2/1900-18 | 5700 | 9005 | |

2.New Technology Description:

Five-ColumnThree-Effect Distillation Process

Our company designs and manufactures latestFive-ColumnThree-Effect Distillation equipment.This new process is promoted on the basisof traditional five-column differential-pressure column and mainly used forsuper-fine alcohol production.

The key of this process is the heatingmethods,the steam heats one column directly andtransfers theheat to other 4 columnsto achieve three-effect thermal couplingand energy-saving effects.

In terms of electricityefficiency, it can save 50% electricity and avoid the repairing ofcirculating pumps and also extend the working life of there-boilers.

Energy Consumption & Quality Indicator Table forSuper-fine Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗汽量Steam Consumption | t/t | 3.0 | 2.3 |

2 | 色度Colority | No. | 9.5 | 8 |

3 | 乙醇 Alcohol | %(v/v) | 95.5 | 96.5 |

4 | 硫酸试验Sulfuric Acid Test | No. | 70 | 9 |

5 | 醛(以乙醛计)Aldehyde (as acetaldehyde) | mg/l | 28 | 2 |

6 | 甲醇Methanol | mg/l | 18 | 3 |

7 | 正丙醇n-propyl alcohol | mg/l | 15 | 2 |

8 | 异丁醇+异戊醇Isobutanol+isoamylol | g/l | 27.5 | 2 |

9 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 9 |

10 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 16 |

11 | 不挥发物Nonvolatile matter | mg/l | 23 | 12 |

12 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.4 |

13 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 2 |

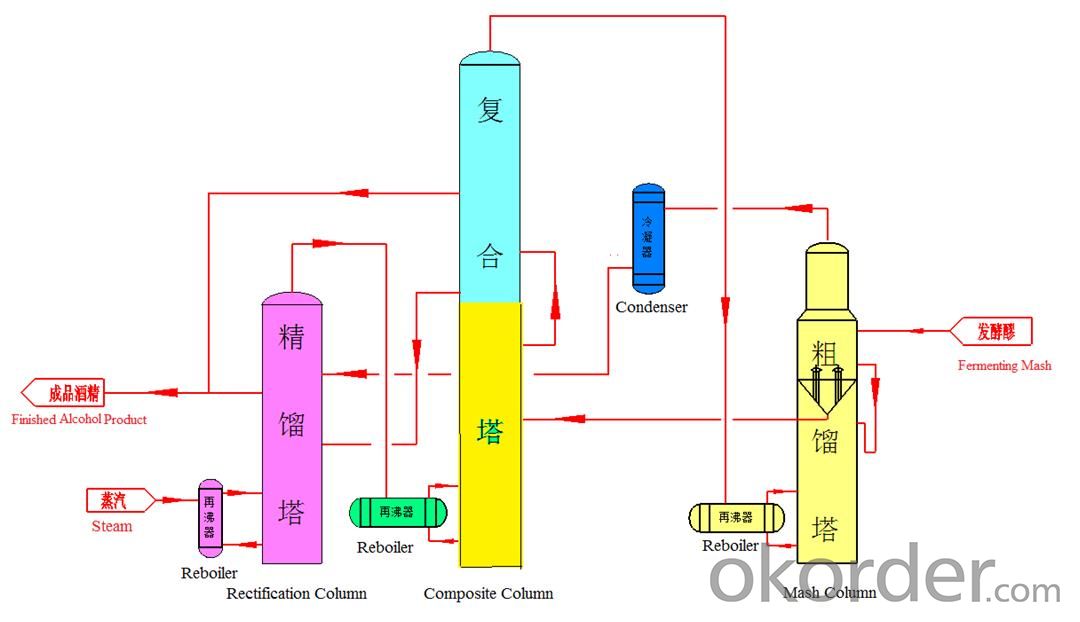

Double-Mash-Column Three-Effect Distillation Process

This process applies to the production ofgeneral-grade alcohol& fuel ethanol, and it was awarded Chinese nationalpatent, it is the onlysuccessfulapplicationof doublemash column & three-effect in the world,whichproduces general-grade alcohol.

This process is composed by mash column,rectification column and composite column. The composite column functions asmash column and rectification column.

The key of this process is the heatingmethods: the steam heats one column directly andtransfers the heat to other 2 columns to achieve three-effect thermal couplingand energy-saving effects.

The advantage of this process is energy-saving;itsaves over 40% steam

Energy Consumption & Quality Indicator Table for General-Grade Alcohol

No. | Item | Unit | Traditional Process | New Process |

1 | 耗电量Electricity Consumption | kwh/t | 15 | 20 |

2 | 耗汽量Steam Consumption | t/t | 2.3 | 1.4 |

3 | 耗水量Water Consumption | t/t | 7 | 5 |

4 | 色度Colority | No. | 9.5 | 8 |

5 | 乙醇 Alcohol | %(v/v) | 95.5 | 95.5 |

6 | 硫酸试验Sulfuric Acid Test | No. | 70 | 55 |

7 | 醛Aldehyde (as acetaldehyde) | mg/l | 28 | 25 |

8 | 甲醇Methanol | mg/l | 100 | 55 |

9 | 正丙醇n-propyl alcohol | mg/l | 75 | 35 |

10 | 异丁醇+异戊醇Isobutanol+isoamylol | mg/l | 27.5 | 26 |

11 | 酸(以乙酸计)Acid(as acetic acid) | mg/l | 19 | 18 |

12 | 脂(乙酸乙酯)Ester (as acetic ether) | mg/l | 22 | 20 |

13 | 不挥发物Nonvolatile matter | mg/l | 23 | 21 |

14 | 重金属(以Pb计)Heavy metal | mg/l | 0.65 | 0.5 |

15 | 氰化物(以Hcn计)Cyanide(as HCN) | mg/l | 3.7 | 3 |

3. Production Capability

1. Our company was established in the 1950s,designed and manufactured the first stainlesssteel distillation column in China.

2. Our company can produce6 full sets of equipment (including crushing section, liquefyingsaccharification section, fermentation section, distillation section and DDGSsection) in a

month.

3. Among 16 production workshops,3 workshops arefor mechanic manufacture, 5 workshops arefor manufacturing process, 8 workshopsare for assembling & welding.

4. We own advanced machining equipment and producttesting equipment.

4. Designed capability

1). We own Design License of SpecialEquipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class;Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patentcertificates on distillation, DDGS, and other fields.

3). Ourcompany owns ASME certification, ISO 9001 Quality System Certification, ISO14001 Environmental Management System Certification & GB/T28001Occupational Health and Safety Management System Certification

5. After-sales Service

1).Our company can provide a sophisticatedproduct after-sale service and can ensure the implementation, maintenance andcommission of projects.

2). We can reach the project site afterreceiving the user’s notification.

6.Package & Transport

- Q: What is the purpose of the heat exchanger on my home's A/C unit?

- If it is an outside unit ... the heat exchanger removes heat from the compressor coils. This works just like a refrigerator. As the compressor works to lower the temperature of the refrigeration liquid, it must remove the heat. The unit (this is how ours works) has a fan that sits in the middle of a housing ... the housing is surrouded by metal tubing. The fan helps to blow air across these tubes to cool them. One of the reasons it's important to keep these units clean (leaves, yard debris, etc), is so the heat is removed efficiently. This allows the unit to operate efficiently and ultimately saves wear on the compressor and energy.

- Q: This is for a science project, so make sure it is not too big or expensive.

- Plastic tubing. Black. In Australia we use black plastic tubing on house roofs to heat pool water. A very shallow tray painted black to absorb heat. Stick to the top a clear piece of perspex with silicon sealant. Have a hose leave the end of the tray and loop around to the other end of the tray to the top of an ice cream bucket. From the bottom of the bucket (side) run a hose to the end of the tray. Place the tray in the sun on an angle with the ice bucket higher. Pour water in the ice cream bucket. Hope you tested for leaks. The cold water will fill the system The sun heats the tray, and the water. The hot water rises up the hose from the top of the tray to the top of the bucket. A cycle begins. Colder water at the bottom of the bucket flows down the hose to the bottom of the tray. Enters , gets hot and cycle continues. For use add tap to near bottom of bucket and top up via float if you want to get fancy. good luck on building your solar hot water system.

- Q: Im doing revision for the next academic year and have lost this particular worksheet.A heat pump is on the back of a fridge and it is what keeps the fridge cold.

- A heat pump is essentially a heat engine in reverse. Working in a reversed Carnot cycle it uses an energy input to move or pump heat from a cold source (e.g. the inside of a refrigerator) to a hot sink (the radiator on the back of a refrigerator). A vapour compression heat pump uses a compressor to raise the pressure and temperature of a refrigerant vapour (compression phase). It then condenses the vapour to a liquid in the hot sink heat exchanger exchanger (cooling phase), drops its pressure and temperature by expanding it through a restrictor or an expansion valve (expansion phase), finally evaporating the cold liquid to a gas in the cold source heat exchanger (heating phase) which in the case of a refrigerator is the cold space inside.

- Q: The unit Im making is brand new, never before seen or even thought about, I need a way to heat air from a controled flame. I need some simple,cheap, and easy to make schematics so I can build it myself. All plans of the unit are confidential.

- Check some of the forced air furnace repair and troubleshooting web sites. I'll bet that if you hunt around a bit you will get enough ideas to design your own pilot and burner flame safety and control systems.

- Q: seperate water cylcle that is entirley outside the reactor. Why is this done

- The water in the reactor becomes radioactive. The heat is passed through a heat exchanger to a different set of water tubes for the steam turbine. Then if steam is released it is not radioactive.

- Q: Checked online, but the first entries were for gall bladder, liver and kidney tests related to a HIDA test.Supposedly it helps find microcracks in the heat exchanger.

- if this is a residential furnace hydroscan is not necessary. there are more accurate ways to test the heat exchanger. there is a smoke bomb test. there is a draft test over the fire before and after the blower runs. these are the old standby test that the industry uses

- Q: My furnace heats for about six and a half minutes (blower running) then goes into the exhaust cycle for about 14 minutes. The furnace is a Bryant Plus 90 furnace that is around 20 years old.

- Sounds like the high temperature limit switch is tripping. Check your air-flow. If you aren't moving enough air through the heat exchanger the high limit will cycle the burners off until it cools down.

- Q: How long will it take to heat 100 litres of water with a 42kW heat exchanger, presuming no heat loss?

- Hello nigel : The water mass, TW1, and TW2 are needed to work this problem : ---------------------------------------... Assume : mw = 50 kg Tw1 = 25 C Tw2 = 75 C Qw = ( mw ) ( Cpw ) ( Tw2 - Tw1 ) Qw = ( 50 kg ) ( 4.184 kJ/ kg - C deg ) ( 75 C - 25 C ) = 10460 kJ t = Qw / Qwdot t = ( 10460 kJ ) / ( 42 kJ per s ) = 249 s <---------------------------------------...

- Q: Can this system be used in conjunction with a baseboard hot water system?Can anyone give me a ball park on the cost for a geothermal system for a 1600 sq ft house in North West New Jersey? I’m genuinely intrigued by this type of system but admittedly know very little about them.Thank you

- I think you mean a Hydroponic heating floor system, where circulated hot water goes through many tubes in beded in the floor to heat the home. Check with home depot.

- Q: From time to time my heater will suddenly start throwing out cold air the thermostat will go down 5-10 degrees lower than it's set at for several hrs. Then for no reason it will start giving out warm air again like it's supposed to. Sometimes it will even go 1-2 degrees higher than originally set before clicking off. It's done it a couple of times a month all this winter. Besides being cold I presume it's wasting energy money. This is the second year it's done it. But it doesn't do it in the summer with the cooling. I use electric for cooling gas for heating. Anyone have any ideas? My nephew has worked with heating/cooling units at work but never heard of anything like this.

- Sounds to me like a fan limit switch sticking closed. That is the component responsible for running the fan until the remaining heat is removed from the heat exchanger. (to keep it from cracking) But, it only does what the thermostat tells it do do.... The heater not initializing and then running too long is the anticipator in the thermostat not set right or not working at all. That component is responsible for turning on the heat before it cools off too much and then telling the heat to shut off before it gets too hot,.... to even out the temperature swing. Your best bet would be to try to get your hands on an old analog thermostat. That may iron out the whole problem.

Send your message to us

The spiral plate heat exchanger (Non-detachable)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords