Special Steel D3M Mould Steel Alloy Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Chemical Composition(GB %)

| C | Si | Mn | Cr | V | S | P |

| 1.4 | 0.35 | 0.35 | 8.00 | 0.15 | ≤0.030 | ≤0.030 |

Available Size

| Rolled flat steel | 12-90mm×205-610mm×L |

Heat Treatment

| Item | Temperature℃ | Hardness |

| Anneal | 850-870 | ≤255HB |

| Quenching | 920-980 | 64-66HRC |

| Tempering | 200 | 61-63HRC |

Characterstics

| 1.New type of chromium containing high carbon cold working die steel | |||||

| 2.Better hardening ability and high abrasion resistance |

Applications: Suitable for various codl working dies with higher abrasion resistance

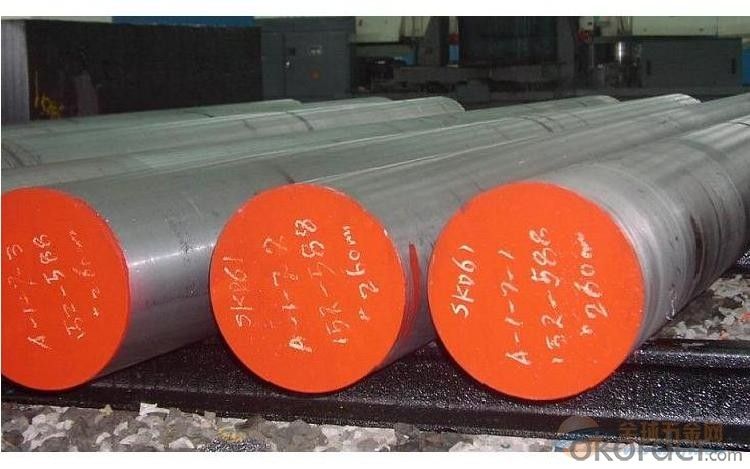

Product Show:

Workshop Show:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

4, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

WE provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the applications of special steel in the food processing industry?

- Special steel has a wide range of applications in the food processing industry due to its unique properties and characteristics. One of the main applications of special steel in this industry is in the manufacturing of equipment and machinery used in food processing plants. Special steel is highly resistant to corrosion and can withstand extreme temperatures, making it ideal for use in food processing equipment that needs to be sanitized frequently and operate in harsh conditions. Special steel is commonly used in the production of blades, knives, and cutting tools used in food processing. The high strength and durability of special steel allow these tools to maintain their sharpness and effectiveness even after prolonged use, ensuring efficient and precise cutting of food products. Another application of special steel in the food processing industry is in the construction of storage tanks and containers. These tanks are used to store and transport various food products, and special steel's corrosion resistance and hygiene properties prevent contamination and ensure the quality and safety of the stored food. Additionally, special steel is also utilized in the construction of processing machinery such as mixers, grinders, and extruders. Its high strength and stability enable these machines to handle the rigorous demands of food processing, ensuring smooth operation and minimizing downtime. Furthermore, special steel is often employed in the production of conveyor systems used in food processing facilities. These conveyors are responsible for moving food products along the processing line, and special steel's resistance to wear and tear means that the conveyor systems can operate efficiently and reliably, reducing the risk of product contamination. In summary, the applications of special steel in the food processing industry are extensive and crucial. From manufacturing equipment to construction and storage, special steel's unique properties play a vital role in ensuring the efficiency, safety, and quality of food processing operations.

- Q: What are the different surface finishing methods used for special steel?

- There are several surface finishing methods used for special steel, each serving a specific purpose and achieving different results. Some of the common surface finishing methods for special steel include: 1. Grinding: Grinding is the process of using abrasive materials to remove excess material from the surface of the steel. It is typically used to achieve a smooth and polished finish, as well as to remove any imperfections or roughness. 2. Polishing: Polishing involves using polishing compounds and abrasive materials to create a smooth and shiny surface on the steel. This method is often used to enhance the aesthetic appeal of the steel and improve its corrosion resistance. 3. Shot blasting: Shot blasting is a technique that involves propelling small metal or mineral particles at high speeds onto the surface of the steel. This process helps to remove any contaminants, scale, or rust from the surface, resulting in a clean and uniform finish. 4. Electroplating: Electroplating is a process where a thin layer of metal is deposited onto the surface of the steel through an electrochemical reaction. This method is commonly used to enhance the appearance of the steel, improve its corrosion resistance, and provide a decorative or protective coating. 5. Passivation: Passivation is a chemical process that involves treating the surface of the steel with an acid solution to remove any impurities and create a passive, corrosion-resistant layer. This method is often used to improve the corrosion resistance of stainless steel and other alloys. 6. Coating: Coating is the process of applying a protective layer or coating onto the surface of the steel. This can include paints, lacquers, enamels, or other types of protective coatings that help to prevent corrosion, improve durability, or provide a specific aesthetic finish. It is important to note that the choice of surface finishing method for special steel depends on the desired outcome, such as aesthetics, corrosion resistance, or functionality. Additionally, the specific characteristics of the steel, such as its composition, hardness, and intended application, also play a significant role in determining the most suitable surface finishing method.

- Q: What are the different classifications of special steel?

- Various types of steel alloys fall under the category of special steel, each possessing unique properties and characteristics that make them suitable for specific applications. Special steel can be classified into several categories: 1. Stainless Steel: This special steel contains a high percentage of chromium, which provides excellent corrosion resistance. It also typically includes elements like nickel and molybdenum, enhancing its strength and durability. Stainless steel finds common use in applications requiring resistance to oxidation, heat, chemicals, and wear, such as in food processing, medical devices, and construction. 2. Tool Steel: Specifically designed for manufacturing tools, dies, and molds, tool steel is known for its exceptional hardness, wear resistance, and toughness. Tool steel is further categorized into subcategories like high-speed steel (HSS), cold work steel, hot work steel, and plastic mold steel, each tailored for specific tooling applications. 3. Alloy Steel: This type of special steel contains additional alloying elements besides carbon. These elements, like manganese, silicon, nickel, chromium, and molybdenum, are added to enhance specific properties such as strength, toughness, hardenability, and corrosion resistance. Alloy steels are used in various applications, including automotive components, machinery, construction, and aerospace. 4. Spring Steel: Specifically designed to withstand repeated bending or twisting without permanent deformation, spring steel possesses excellent elasticity and fatigue resistance. It finds applications in springs, suspension systems, and high-performance automotive parts. 5. Bearing Steel: Bearing steel is engineered to provide high hardness, wear resistance, and dimensional stability necessary for manufacturing bearings. It typically contains high levels of carbon, chromium, and other alloying elements, ensuring the required mechanical properties for reliable and long-lasting bearings. 6. Electrical Steel: Also known as silicon steel, electrical steel is specifically designed for electrical applications. It possesses low electrical resistivity and high magnetic permeability, allowing efficient conduction and transformation of electrical energy. Electrical steel is commonly used in transformers, electric motors, and generators. These classifications of special steel emphasize the versatility and tailored properties of different steel alloys, enabling their application in a wide range of industries and specialized uses.

- Q: What are the factors to consider when selecting special steel for a specific application?

- When selecting special steel for a specific application, some important factors to consider include the required strength and hardness, corrosion resistance, temperature resistance, machinability, weldability, and cost. Other factors may include the desired surface finish, dimensional stability, availability, and any specific industry or regulatory requirements.

- Q: What are the specific requirements for special steel used in the marine propeller industry?

- The special steel used in the marine propeller industry must meet specific requirements to ensure optimal performance and durability in harsh marine environments. Some of the key requirements include: 1. Corrosion Resistance: Marine propellers are constantly exposed to saltwater, which can cause corrosion. Therefore, special steel used in the marine propeller industry must have high resistance to corrosion, preventing the formation of rust and maintaining the propeller's integrity over time. 2. Strength and Toughness: Marine propellers are subjected to high mechanical stresses and impacts, especially in rough sea conditions. The special steel used must possess high strength and toughness to withstand these forces without deformation or failure. 3. Fatigue Resistance: Propellers experience cyclic loading due to rotational forces, which can lead to fatigue failure over time. The special steel should have excellent fatigue resistance to withstand millions of load cycles without developing cracks or fractures. 4. Weldability: Propellers are often manufactured in segments and then welded together. The special steel used must be easily weldable, ensuring strong and reliable joints that can withstand the propeller's operational stresses. 5. Heat Resistance: Propellers generate significant heat due to friction and propulsion forces. The special steel should have good heat resistance to prevent deformation or loss of mechanical properties at elevated temperatures. 6. Machinability: Special steel used in the marine propeller industry should be readily machinable to allow for precise shaping and finishing of complex propeller blade designs. 7. Non-Magnetic Properties: Many modern ships utilize magnetic navigation systems and sensors. Therefore, the special steel used in propellers should have low magnetic permeability to minimize interference with these systems. Meeting these specific requirements ensures that the special steel used in the marine propeller industry can withstand the challenging conditions of seawater, provide efficient propulsion, and maintain its structural integrity throughout the propeller's lifespan.

- Q: What are the different medical grades of special steel?

- Special steels used in the medical field are typically classified into different grades based on their unique properties and characteristics. These grades are specifically designed to meet the stringent requirements of medical applications, such as surgical instruments, implants, and medical devices. Some of the commonly known medical grades of special steel include: 1. Stainless Steel: Stainless steel is the most widely used medical grade of special steel due to its excellent corrosion resistance and biocompatibility. It contains high amounts of chromium and nickel, which provide resistance against corrosion and make it suitable for use in implants and surgical instruments. 2. Titanium Alloys: Titanium alloys are lightweight yet strong, making them ideal for medical applications such as orthopedic implants, dental implants, and cardiovascular devices. These alloys exhibit high biocompatibility and have excellent resistance to corrosion and fatigue, ensuring long-term durability. 3. Cobalt-Chromium Alloys: Cobalt-chromium alloys possess exceptional strength, wear resistance, and high-temperature stability, making them suitable for implantable devices like hip and knee replacements. They have excellent biocompatibility and offer a good balance between strength and flexibility. 4. Nitinol: Nitinol is a shape memory alloy composed of nickel and titanium. It displays unique properties, such as superelasticity and shape memory effect. Nitinol is commonly used in medical devices like stents, orthodontic wires, and vascular closure devices due to its excellent biocompatibility and ability to adapt to various physiological conditions. 5. High Carbon Stainless Steel: High carbon stainless steel is a specialized grade used in surgical instruments that require exceptional sharpness, hardness, and wear resistance. This grade allows for the production of extremely fine and precise cutting edges, making it suitable for delicate procedures. These are just a few examples of the medical grades of special steel used in the healthcare industry. Each grade offers specific advantages depending on the intended application, and their selection is crucial to ensure optimal performance, biocompatibility, and patient safety.

- Q: What are the challenges in welding special steel?

- One of the main challenges in welding special steel is its high carbon content, which can lead to increased difficulty in achieving proper fusion and producing a sound weld. Additionally, special steels often have alloying elements that can affect their weldability, such as increased susceptibility to cracking or reduced ductility. Another challenge is the potential for distortion or warping during the welding process due to the high heat input required. Overall, welding special steel requires careful consideration of the material's composition and properties to ensure successful and reliable welds.

- Q: What are the different tooling grades of special steel?

- Special steel is a category of steel that has been designed and manufactured to possess specific characteristics or properties, making it well-suited for various industrial applications. Within special steel, there are different tooling grades available, each with its own unique composition and properties. These grades are specifically engineered to meet the demands of different tooling applications, ensuring optimal performance and durability. Some common tooling grades of special steel include: 1. High-Speed Steel (HSS): HSS is a type of tool steel that exhibits excellent hardness, wear resistance, and heat resistance, making it ideal for high-speed cutting tools such as drills, milling cutters, and taps. It retains its hardness even at elevated temperatures, enabling it to maintain cutting performance without losing its edge. 2. Hot Work Tool Steel: Hot work tool steel is designed to withstand high temperatures and thermal cycling encountered in applications such as hot forging, die casting, and extrusion. It possesses good toughness, high heat resistance, and excellent wear resistance, allowing it to retain its strength and shape even under extreme thermal conditions. 3. Cold Work Tool Steel: Cold work tool steel is primarily used for cutting and forming applications at lower temperatures. It exhibits a high level of hardness, toughness, and wear resistance, making it suitable for applications such as blanking, shearing, and cold forming. Cold work tool steel maintains its hardness even under compressive forces, ensuring long-lasting performance. 4. Plastic Mold Steel: Plastic mold steel is specifically designed for the production of plastic injection molds and related tooling. It possesses excellent machinability, high polishability, and good wear resistance, allowing it to withstand the demanding conditions encountered during plastic molding processes. Plastic mold steel ensures precise and high-quality molding performance. 5. Powder Metallurgy (PM) Steel: PM steel is a tooling grade that is manufactured using a powder metallurgy process. This method allows for the production of complex shapes, uniform microstructure, and improved properties. PM steels are commonly used in high-performance cutting tools, wear-resistant parts, and high-strength applications. These are just a few examples of the different tooling grades available in special steel. Each grade is carefully engineered to meet the specific requirements of various tooling applications, ensuring optimal performance, durability, and efficiency in different industrial sectors.

- Q: How is electrical steel used in the manufacturing of transformers?

- Electrical steel, also known as transformer steel, is a specialized type of steel used in the manufacturing of transformers. It is primarily used as the core material in transformers due to its unique magnetic properties. The core is responsible for transferring electrical energy from the primary coil to the secondary coil by creating a magnetic field. Electrical steel's low core losses and high magnetic permeability make it ideal for this purpose. Its high silicon content helps reduce energy loss and heat generation, improving the efficiency of transformers.

- Q: What are the requirements for special steel used in chemical processing?

- The requirements for special steel used in chemical processing are generally more stringent compared to regular steel due to the harsh and corrosive nature of the chemicals involved. Some of the key requirements for special steel in chemical processing include: 1. Corrosion resistance: Special steel used in chemical processing must exhibit high resistance to corrosion from acids, alkalis, and other corrosive chemicals. This is achieved by adding alloying elements such as chromium, nickel, and molybdenum, which form a protective oxide layer on the surface of the steel, preventing it from reacting with the chemicals. 2. High temperature resistance: Chemical processing often involves high-temperature reactions. Therefore, special steel used in this industry must have excellent heat resistance to maintain its strength and structural integrity at elevated temperatures. This is achieved by adding elements like chromium, nickel, and tungsten, which help in maintaining the stability of the steel at high temperatures. 3. Mechanical strength: Special steel used in chemical processing should possess sufficient mechanical strength to withstand the pressures and loads encountered in the process equipment. This requirement is met by adding alloying elements such as manganese, silicon, and carbon, which enhance the steel's strength and toughness. 4. Weldability: Weldability is a crucial requirement for special steel used in chemical processing as it allows for easy fabrication and installation of process equipment. Special steel with good weldability ensures strong and reliable joints, which are essential for the safe and efficient operation of chemical plants. 5. Resistance to stress corrosion cracking: Stress corrosion cracking is a significant concern in chemical processing environments. Therefore, special steel used in this industry should have good resistance to stress corrosion cracking, which is achieved by carefully selecting the alloying elements and controlling the material's microstructure. 6. Cleanliness: Special steel used in chemical processing should be free from impurities and have a low content of harmful elements that could contaminate the process or react with the chemicals. This necessitates strict quality control measures during steel production to ensure the desired cleanliness and purity. Meeting these requirements ensures that special steel used in chemical processing can withstand the aggressive chemical environment, high temperatures, and mechanical stresses encountered in the industry, leading to safe and reliable operation of the process equipment.

Send your message to us

Special Steel D3M Mould Steel Alloy Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords