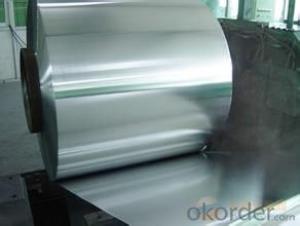

cold rolled steel Coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Specification:

COLD ROLLED STEEL | |

Thicknenss | 0.10mm-4.00mm |

Width | 600mm-2000mm |

Sheets length | 1200-6000mm |

Coil inner diameter | 508-610mm |

Surface treatement | matt finish/bright finish,oiling/dry, bright anneal/black anneal |

Coil weight | 3-5t |

Application:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Images:

Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

FAQ

1. Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.for quality inspection every day.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q: What is the role of steel coils in the production of storage shelves?

- Steel coils play a crucial role in the production of storage shelves as they are used as the primary material to create the structural components of the shelves. These coils are flattened, cut, and formed into various shapes and sizes to construct the frames, supports, and shelves themselves. The durability and strength of steel coils ensure that the storage shelves can withstand heavy loads and provide long-lasting storage solutions.

- Q: How are steel coils handled during loading and unloading?

- Steel coils are typically handled using cranes, forklifts, or coil hooks during loading and unloading. The coils are carefully lifted, secured, and transported to their respective destinations. Special attention is paid to ensure proper balance, stability, and safety measures are followed to prevent any damage or accidents during the process.

- Q: How do steel coils contribute to the manufacturing of construction materials?

- Steel coils contribute to the manufacturing of construction materials by providing a reliable and versatile raw material. These coils are typically made from high-quality steel and can be easily shaped, cut, and formed into various components such as beams, pipes, and sheets. The strength and durability of steel make it ideal for use in construction, ensuring the integrity and longevity of buildings and structures. Additionally, the consistent quality and availability of steel coils enable efficient and cost-effective production processes, making them an essential element in the manufacturing of construction materials.

- Q: What are steel coils used for?

- Steel coils are used in a wide range of industries and applications, including manufacturing, construction, automotive, and appliances. They are commonly used in the production of various metal products such as pipes, tubes, sheets, and wires. Steel coils provide strength, durability, and versatility, making them essential in many industrial processes.

- Q: What are the common methods of joining steel coils together?

- The common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), and adhesive bonding.

- Q: How are steel coils processed and shaped for specific applications?

- Steel coils are processed and shaped for specific applications through a series of steps. First, the coils are uncoiled and flattened to remove any bends or curls. Then, they undergo various processes such as cutting, slitting, or shearing to achieve the desired dimensions. Next, the steel is often subjected to heat treatment, such as annealing or tempering, to enhance its strength and flexibility. Finally, the steel is shaped into specific forms using techniques like rolling, bending, or stamping, to meet the requirements of different applications ranging from automotive parts to construction materials.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- I honestly don't like riding with heavy boots on my sport bikes. It it tough to get a feel for where neutral is, and there really isn't a ton of clearance between the peg and the shift lever. I prefer lighter, more flexible boots like my old desert combat boots. They are really well broken in and you can really feel what's going on. When I ride a bike with a heal-toe shift like my old Roadking, it doesn't matter nearly as much. You could probably shift pretty well wearing ski-boots. As long as they give you enough feel for the shift lever, any boots will probably be fine though.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials. This coating process enhances the electrical conductivity of the steel coils and allows them to conduct electricity efficiently.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide strength, durability, and energy absorption capabilities. These coils are typically formed into various shapes and sizes to create components that reinforce the vehicle's body, such as side impact beams or front and rear crumple zones. The steel coils absorb and distribute the impact energy during a crash, helping to protect the occupants by minimizing the force transferred to the passenger compartment.

Send your message to us

cold rolled steel Coil / sheet / plate -SPCG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords