Smooth Two Coat Finish Aluminum Coil for Cable Shield with High Quality and Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Coil for Cable Shield with High Quality and Cheap Price

l Product Introduction

Alloy: 1000 series, 3000 series, 8000series

Temper: O H22 H24 H26 H28

Apply: bill board, selectronic circuit board, building exterior decoration, curtain wall plate,reflective devices,etc.

Thickness: 0.2-2.0mm

Length: 1000-6000mm

Width: 1100-1700mm

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| 1100, 1050, 3003, 8011 | 0.2-2.0 | 1100-1700 | 1000-6000 | O, H22, H24, H26, H28 | |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

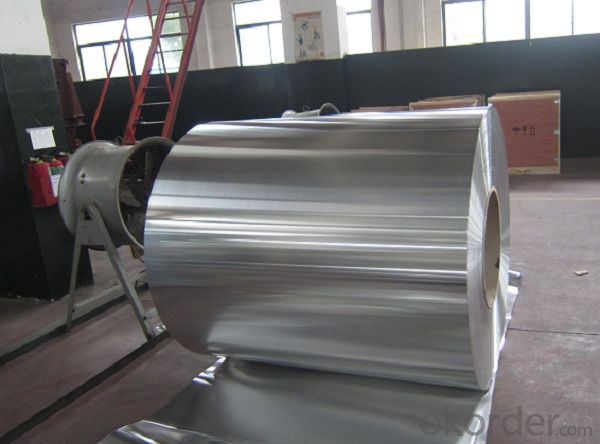

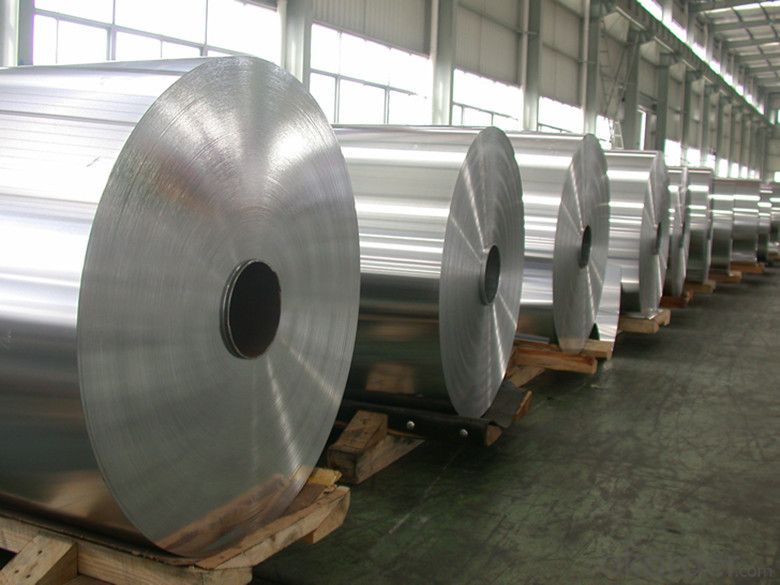

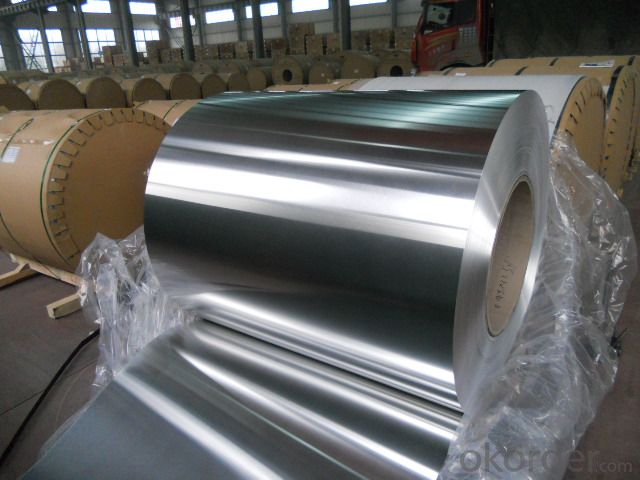

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What should pay attention to transporting aluminum coil?

- You must ensure the good property of the aluminum coil.

- Q: This question asks if aluminum coils are susceptible to rusting.

- <p>Aluminum coils do not rust in the traditional sense. Aluminum reacts with oxygen in the air to form a thin, protective layer of aluminum oxide on its surface, which prevents further corrosion. This oxide layer is different from rust, which is iron oxide. While aluminum can tarnish or corrode under certain conditions, such as exposure to certain chemicals or harsh environments, it does not rust like iron or steel. Proper storage and handling can help maintain the integrity of aluminum coils and prevent any form of corrosion.</p>

- Q: What precautions should be taken to ensure the safe and efficient transportation of aluminum coils?

- <p>The best way to handle aluminum coil during transportation involves using proper lifting equipment, ensuring secure strapping, and maintaining a stable and dry environment. Use slings or lifting beams specifically designed for metal coils to prevent damage. Ensure the coil is strapped tightly to prevent shifting during transit. Keep the coils covered to protect from moisture and dirt. Always follow the manufacturer's guidelines for weight limits and handling procedures.</p>

- Q: This question asks for the cost of an aluminum coil, which can vary based on factors such as weight, quality, and market conditions.

- <p>The cost of an aluminum coil can vary significantly based on its weight, grade, and current market prices. As of my last update, the price per pound can range from about $0.30 to $1.50, but this is subject to change with market fluctuations. For precise pricing, it's best to check with a supplier or on a commodity exchange, as aluminum prices are dynamic and influenced by global supply and demand.</p>

- Q: How do aluminum coils contribute to energy efficiency?

- Aluminum coils contribute to energy efficiency in several ways. Firstly, aluminum is a highly conductive metal, which means it can efficiently transfer heat. When used in HVAC systems, aluminum coils help in the efficient transfer of heat between the air and the refrigerant, allowing for quicker cooling or heating of the space. Secondly, aluminum coils are lightweight and have a high strength-to-weight ratio. This characteristic makes them easier to handle and install, reducing the overall weight of the HVAC system. The reduced weight not only makes transportation and installation more efficient but also reduces the load on the building structure. Furthermore, aluminum coils are durable and corrosion-resistant. This longevity ensures that the HVAC system operates smoothly over an extended period, minimizing the need for frequent repairs or replacements. As a result, less energy is wasted on maintaining or replacing components, leading to better energy efficiency. Additionally, aluminum is a recyclable material, and using aluminum coils in HVAC systems promotes sustainability. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, thus reducing the overall carbon footprint and energy consumption. Lastly, aluminum coils are often manufactured with enhanced fin designs and advanced technology, such as microchannel coils. These innovations increase the surface area of the coil, improving heat transfer efficiency and reducing the energy required for cooling or heating. Overall, aluminum coils contribute to energy efficiency by facilitating efficient heat transfer, reducing system weight, promoting durability, supporting sustainability through recycling, and incorporating advanced technology to enhance heat exchange.

- Q: Can aluminum coils be used in the production of cans?

- Yes, aluminum coils can be used in the production of cans. Aluminum coils are commonly used in the manufacturing process of cans due to their lightweight, durability, and corrosion resistance. These coils are typically shaped into sheets that are then formed into cans, making them a popular choice for the production of beverage and food containers.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: Can aluminum coils be welded or soldered?

- Aluminum coils possess the capability of being both welded and soldered. The fusion of aluminum coils can be achieved through welding or soldering, which are two widely employed techniques in this regard. Welding entails the melting of the aluminum material within the coils, followed by the application of heat and pressure to bind them together. This particular procedure necessitates the utilization of specialized equipment and skilled operators. Conversely, soldering is a process that utilizes solder, a filler material with a lower melting point, to connect the aluminum coils. Soldering is commonly employed in lighter applications and necessitates less heat compared to welding. Both welding and soldering are effective methods for joining aluminum coils. However, the selection between these two techniques depends on the project's specific requirements, the availability of equipment, and the proficiency of the operator.

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- When it comes to durability, aluminum coils outperform plastic coils. Aluminum is renowned for its strength and ability to resist wear and tear, making it a highly durable material. It can withstand heavy usage without cracking, breaking, or deforming under pressure. In contrast, plastic coils are more susceptible to damage, particularly with repetitive use or extreme temperatures. Although plastic coils may be cost-effective and lightweight, they may not maintain their quality over time. Consequently, for those prioritizing durability, aluminum coils are the superior option due to their longer lifespan and increased resistance to damage.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

Smooth Two Coat Finish Aluminum Coil for Cable Shield with High Quality and Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords