Small industrial induction furnace machinery 20KW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Small Induction Furnace

1.Based on latest IGBT

2.Especially suitable for laboratory use

3.Ensure safety

4.Energy saving

20kw small industrial induction furnace machinery

About induction heating

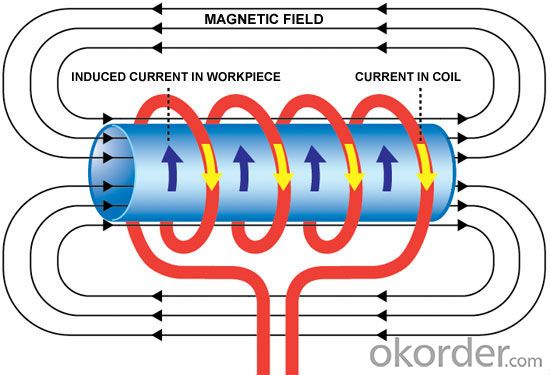

Induction heating is a form of non-contact heating for conductive materials. When alternating current flows in

induced coil, varying electromagnetic is set up around the coil, eddy current is generated in the workpiece

( the workpiece must be electrically conductive).

![]()

Rated Power output | 20KW |

3 phase input(V/Hz) | 380V/50Hz |

Operating voltage | 380V |

Input power | 22KW |

Oscillation frequency | 20-50KHZ |

Efficiency | 90% |

Duty cycle | 100% |

Current input | 30-40A |

Voltage range | 360-420V |

Cooling water flow | 24L/Min |

Water temperature protection point | 45°C |

Weight of power unit | 65-75kg |

Dimension of power unit(mm 3) | 500*400*650mm³ |

![]()

Main feature

induction heating work

IGBT power supply

safe and stability

environmetal and save energy

installation simple , operate easy

small size , move conveninetly

heating fast , heating uniformity

we can offer

induction heating equipments

induction coil ( the coil to be made depend on your heating work requirements and the size of your workpieces )

operation manual

![]()

smelting for iron , steel , cooper , aluminum

smelting for presious metals , such as gold , sliver ,

smelting for ferrous and non ferrous metals

smelting for alloys

smelting for metal rods

other smelting work for metal products

- Q: Selection of heat preservation material for industrial furnace

- In the neutral and oxidizing atmosphere, the tensile strength, toughness and fiber structure can be maintained for long term use. The temperature is 950-1400 centigrade. Excellent chemical stability; excellent thermal stability; excellent tensile strength; low thermal conductivity; low thermal capacity; excellent sound absorption and noise reduction performance.

- Q: What is the difference between industrial furnaces and boilers?

- Industrial kilns and industrial furnaces are collectively referred to as industrial furnaces. Industrial furnaces mainly refer to devices that heat materials by combustion reactions.

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The main equipments of heat treatment are classified into two major categories: main equipment and auxiliary equipment. The main equipment includes heat treatment furnace, heating device, surface modification, surface oxidation device, surface mechanical enhancement device, cooling equipment, cold processing equipment, process parameter detection and control instrument; auxiliary equipment includes cleaning cleaning equipment, furnace atmosphere heating medium permeability meter preparation equipment, cooling device, quenching medium heavy transport machinery, quality testing equipment, power transmission line and auxiliary equipment, fire safety equipment, dust and other production fixture.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- This series of electric furnace is made of super light refractory fiber. The electric stove and the temperature control cabinet matching use, the controller may automatically or the manual control electric stove temperature, may press the user request to provide the computer table or the computer control, does the multielement temperature measurement, guarantees the product quality. This series of electric furnaces are periodical operation type electric furnaces.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Of course, the difference is like the difference between a hog cap and a 100 story building. See the industrial furnace manual.

- Q: How to use industrial furnace equipment?

- If it is water cooling furnace door, but also to ensure the smooth flow of pipes, winter pipes are not frozen. When the boiler is in a limited position, the interlocking device for cutting off the power supply shall be provided when the furnace is in and out, and the number of broken wires in the pitch of the steel wire shall not exceed 10%, and the counterweight of the furnace door shall be reliably hung.

Send your message to us

Small industrial induction furnace machinery 20KW

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches