Providing 220v/380v 16kw-260kw high frequency small induction furnace

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard wooden case for motor for high frequency small melting furnace |

| Delivery Detail: | 1week after payment |

Specifications

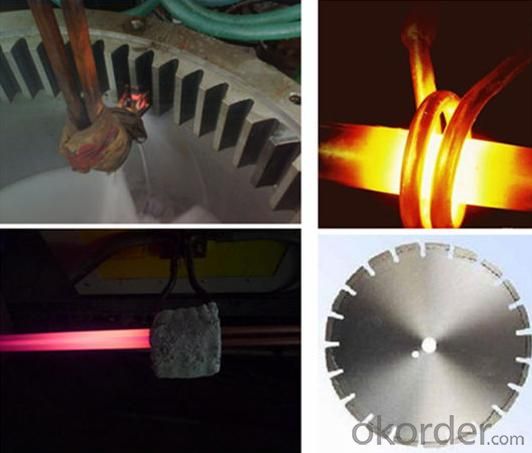

high frequency small melting furnace

1,save 40-60% energy

2,save 20% energy,comparing with thyristor

3, save 60% water

220v/380v 16kw-260kw high frequency small melting furnace

Process Management:

![]()

Welding & Machining MPP • Welding Process Flow Chart • Welding Procedure • Heat Treatment Procedure

Assembly Procedure • Painting Procedure • Lifting Procedure

Workshop Facilities (Phase 1):

![]()

Welding workshop | Material preparation workshop | Machining workshop | Assembly workshop | |

Dimension | 205m×36m×2 | 156m×26m | 217m×36m×2 | 217m×36m |

Overhead crane | 2×150T/16m | 75T/16m | 2×150T/16m | 2×150T/16m |

Main gate | 16m×12m | 12m×10m | 16m×12m | 16m×12m |

| ||||

After-sales Service:

![]()

Supervision for Installation, Commissioning & Training for Operation & Maintenance

Pictures:

![]()

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q: What's the role of anchor bricks in industrial furnaces?

- The wall of an industrial furnace or flue is mainly composed of an inner lining layer, a heat insulating layer and an outer wall layer. The lining is a refractory brick, and the outer wall is an ordinary sintered brick.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Electric furnace is divided into four categories: resistance furnace, induction furnace, arc furnace and special electric furnace according to the different ways of electric heating.

- Q: What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

- Q: What is an industrial furnace pit?

- Later, a chamber kiln with a semi closed or fully enclosed kiln made of refractory bricks can be used as fuel for coal, gas or oil, and electricity can be used as heat source. The workpiece will be heated in the kiln hearth.

Send your message to us

Providing 220v/380v 16kw-260kw high frequency small induction furnace

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches