industrial smelting furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

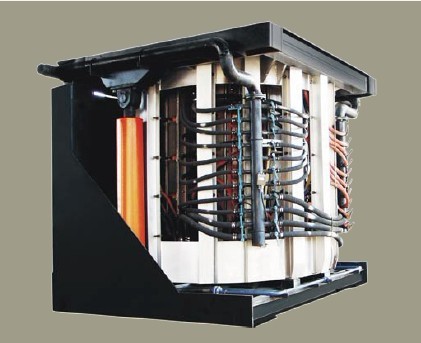

Our industrial smelting furnace and medium Frequency Induction Furnace with technology of dual Track furnaceDual Track furnace

Our industrial smelting furnace for melting steel to produce billets and rebar etc.Detail spec.:

1ton Dual track KGPS induction furnaceMedium Frequency Induction Furnace Dual Track furnace

Technical parameter

Item | Unit | Data |

Furnace parameter |

| 1t |

Rated capacity | t | 1 |

Maximum capacity | t | 1.2 |

Induction coil inside diameterΦ | mm | 700 |

Induction coil height | mm | 820 |

Maximum working temperature | °C | 1750 |

Electrical parameter |

|

|

Transformer capacity | KVA | 1000 |

Transformer primary voltage | KV | 10 |

Transformer secondary voltage | V | 660 |

Rated power of MF power supply | KW | 800 |

Maximum output voltage of MF power supply | V | 1450 |

Coil voltage | V | 2900 |

Rated working frequency | Hz | 1000 |

Power supply convert frequency | % | 96 |

Startup successful frequency | % | 100 |

Composite parameter |

|

|

Melting rate(rise to 1450°C) | t/h | 1.4 |

Melting power consumption (rise to 1450°C) | KW.h/t | 580 |

Working noise | db | ≤75 |

Hydraulic system |

|

|

Hydraulic station capacity | L | 200 |

Working pressure | MPa | 11 |

Hydraulic medium |

| Hydraulic oil |

Cooling water system |

|

|

flow | M3/h | 34 |

Water supply pressure | MPa | 0.2~0.3 |

Inlet water temperature | °C | 5~35 |

Outlet water temperature | °C | 35~55 |

The way of rectifier transformer what is our company recommended as follow:

The specification of rectifier transformer (double 6-pulse)

Furnace capacity | Power of MF power supply(KW) | Transformer Capacity(KVA) | Voltage combination | Coupling group mark | Impedance voltage (%) | |

Primary side (KV) | Secondary side (V) | |||||

1t | 800 | 1000 | 10 | 660 | Δ/Y0-12 | 6~8 |

0

1 Remark:It should be has no-load voltage adjustment switch in high voltage side of transformer, the voltage is adjusted at -0.5%, 0, +0.5% 3 level.

The rectifier tube and inverter tube are chosen as follow specification:

Furnace model | KK tube | KP tube |

1t | KK—1200A/1800V | KP—1000A/2200V |

- Q: Selection of heat preservation material for industrial furnace

- Micro nano heat insulation board.The thermal conductivity of micro nano heat insulation board is very low, only a fraction of the traditional thermal insulation material, and the insulation effect is very efficient.

- Q: What is the difference between industrial furnaces and boilers?

- A boiler is a mechanical device for heating water into hot water or steam by the use of heat from fuel or other sources of energy. The original meaning of a pot is a water container heated by fire. The furnace is the place where the fuel is burned. The boiler includes two parts, the cooker and the furnace.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- There are many kinds of furnaces in metallurgical industry,colored and black,smelting and heat treatment are also included.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: What is industrial furnace masonry?

- Before masonry construction, the pre process and parts that may affect the quality of masonry work shall be re tested,masonry construction shall be carried out according to the datum central line and the datum elevation.

- Q: What's the role of anchor bricks in industrial furnaces?

- Anchorage brick is a new type of anchor brick relates to an industrial furnace, in particular to anchor brick of an industrial furnace roof, including column hanging end and the anchor structure, opened in the anchor on the surface of the spacing of the grooves in the anchor on at least one surface is arranged along the length direction ribs is provided with ribs, the ribs of the reinforcement and anchorage tension, tensile and flexural strength was obviously improved, the stress generated in the groove at the bar at the barrier can not continue to transfer, so the anchor brick of this kind of structure is not easy to break.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What are the advantages of a vacuum furnace?

- No pollution to the environment, no need for three wastes treatment.

- Q: What is an industrial furnace pit?

- The creation and development of industrial kilns play an important role in the progress of mankind. Chinese appeared more perfect in the Shang Dynasty copper smelting furnace, furnace temperature is up to 1200 DEG C, up to 0.8 meters in diameter kiln stove.

Send your message to us

industrial smelting furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords