Small Hydraulic Pump 2CY Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Export standard wooden pallet or user-defined. |

| Delivery Detail: | within 7 days after recieving payment(according to order QTY) |

Specifications

Mainly used for firing boiler hydraulic aspects.

High hardness and wear property.

Stable pump pressure, little discharge.

Small Hydraulic Pump

General Purpose Pumping manufacture Small Hydraulic Pump 2CY pump

2CY Small Hydraulic Pump's Application

2CY series pump applies to delievering non-corrosive lubricating-oil or equivalent liquid without solid particles.

It applies to hydraulic system,too.

Application fields:

Oil, Petrochemical, Chemical, Mining, Metallurgy, Electricity, Shipbuilding, Textile dyeing and printing, Paper manufacturing, Construction, Medicine, Foodstaff industries, ect.

If you are looking for Small Hydraulic Pump, maybe you need it -- 2CY Gear Pump ö.ö

| Name | 2CY Small Hydraulic Pump | |

| Type | 2CY SMALL GEAR PUMP | |

| Application | •Professional hydraulic oil pump •Transfer pump or booster pump •Fuel pump •Lubricating pump | |

| Material | Pump casing | 1.Cast iron (HT200, HT250) 2.Nodular cast iron (QT450) |

| Gear | 1.40Cr 2.38CrMoAl | |

| Capacity | 1.08~12 m3/h | |

| Viscosity | 5~1500cSt | |

| Temperature | <300°c | |

| Pressure | 2.5Mpa (max pressure is 4.0Mpa) | |

| Speed | 1420~1460r/min | |

| NPSH | 9.5m | |

Suction head | 0.5m | |

| Motor type | Normal type, Explosion-proof type, Shipborne type | |

| Advantage | Higher hardness and wear property | |

| Shaft seal | Mechanical seal or packing seal | |

More Details:

| MOQ | 1SET |

| Certification | GL, ABS, BV, CE, DNV |

| Package | Standard export carton or plywood case |

| Delivery date | Within 25 working days after confirm order |

| Warranty | 1 year |

| Customized | Available |

2CY Small Hydraulic Pump

Application Scope of Small Hydraulic Pump

1.Transfer pump or booster pump in oil delivery system.

2.Fuel pump for delivery, pressurization and injection in fuel supply system.

3.As hydraulic pump supplying hydraulic power in hydraulic system.

4.As lubricating pump in all dustry field.

5.The pressure can reach up 4.0Mpa.

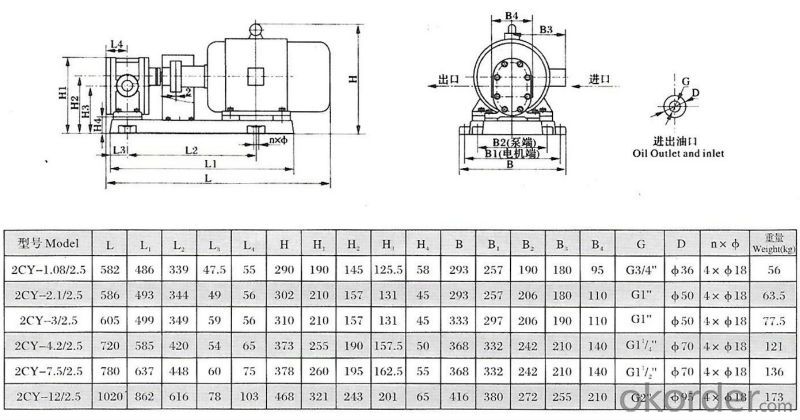

Small Hydraulic Pump Structural Diagram

Functional data

| Model | Capacity | Speed (r/min) | Exhust pressure (Mpa) | NPSH (m) | Efficiency (%) | Motor | ||

| m3/h | L/min | Power(KW) | Model | |||||

| 2CY-1.08/2.5 | 1.08 | 18 | 1420 | 2.5 | 9.5 | 58 | 2.2 | Y100L1-4 |

| 2CY-2.1/2.5 | 2.1 | 35 | 1420 | 2.5 | 9.5 | 58 | 3 | Y100L2-4 |

| 2CY-3/2.5 | 3 | 50 | 1440 | 2.5 | 9.5 | 59 | 4 | Y112M-4 |

2CY-4.2/2.5 | 4.2 | 70 | 1440 | 2.5 | 9.5 | 62 | 5.5 | Y132S-4 |

| 2CY-7.5/2.5 | 7.5 | 125 | 1440 | 2.5 | 9.5 | 63 | 7.5 | Y132M-4 |

| 2CY-12/2.5 | 12 | 200 | 1460 | 2.5 | 9.5 | 61 | 15 | Y160L-4 |

♥Dear friend, please provide me parameter of detailed information such as medium nature, capacity, pressure and meterial of pump so on. We will help choosing the most suitable pump with best quality for you.

Note:Pumps above can be matched with different motor as customer requirment.

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

| | | | | | | |

- Q: What are the ways of hydraulic pumps?

- Hydraulic pump is a power component of hydraulic system. It is driven by an engine or an electric motor. It draws oil from the hydraulic tank to form a component of the pressure oil which is sent to the actuating element.

- Q: What is the principle of a turbopump?

- Turbine [turbine] is a machine that converts the energy contained in a fluid medium into mechanical work, also called a turbine. Turbine is the transliteration of English turbine, derived from the Latin word "turbo", meaning "rotating object".

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- The working principle of submersible pumpBefore the pump is opened, the suction pipe and pump must be filled with liquid. Open the pump, the impeller rotating speed, which leaves the liquid together with the rotation under the action of centrifugal force, the left outside impeller injection, injection of the liquid in the pump shell gradually slow the spread of indoor speed, the pressure gradually increased, and then from the pump outlet, the outflow discharge tube. At this time, in the leaves at the center of the vacuum area of low pressure liquid was thrown to the surrounding formation there is no air and no liquid, liquid pool at the surface of the liquid under the action of atmospheric pressure, through the suction pipe into the pump, the liquid is continuously pumped up from the liquid pool is also continuously from the outflow discharge tube.

- Q: Bolus dosage of infusion pumpWhat is the purpose of the pill dose control in the special safety standard for infusion pumps? If the risk is not properly controlled, what is the degree of risk? And how can the open infusion pump be used in this regard?

- Four) release bolus dosage method can use automatic release and manual release two ways, the key is to alarm after the infusion must be stopped(five) any kind of pill dose release are not restricted to replace the pill. The total dose limit for in pipe blockage after pill agglomeration process will remove blocking accident, this time will be the rapid infusion of pill dose concentration into the patient's blood, if the total dose pill does not get test and limit, rapid infusion of this accident it may have unimaginable consequences.(six) supplies open type infusion pump overflow on the domestic market for pill characteristic parameters of consumables simply without testing and limitation. Therefore, the risk of accidental pill has become one of the residual risk of open type infusion pump supplies the most deadly.

- Q: Is the centrifugal pump large or small?

- When the liquid is lowered at a certain temperature to the vapor pressure at this temperature, the liquid bubbles. The phenomenon of producing bubbles is called cavitation. When the bubbles are flowing to the high pressure, the volume of the bubbles is reduced so that they are destroyed. This due to the pressure of rising bubbles disappear in the liquid in the phenomenon called cavitation bubble collapse. The local pump is in operation if the over-current part (usually the impeller blade inlet somewhere later) for some reason, the absolute pressure of pumping the liquid was reduced to liquid vapor pressure temperature, liquid vaporization began there, produce a lot of steam bubble formation, when the liquid contains a lot of bubbles by forward high pressure impeller Zone, high pressure liquid around the bubbles in the bubble decreases drastically and rupture. Condensation in the bubble burst and the liquid particle at high speed to fill a hole in this moment has a very strong effect of water hammer and the impact of high frequency against the metal surface, the impact stress of hundreds to thousands of atmospheric pressure, impact frequency can be up to tens of thousands of times per second, serious breakdown when the wall thickness will be. The process of cavitation in a pump is caused by the bursting of bubbles and bubbles in the water pump and the destruction of the over-current components. Water pump cavitation, in addition to the over-current components will have a destructive effect, but also produce noise and vibration, and lead to the performance of the pump down, seriously when the pump will be interrupted liquid, can not work properly.

- Q: What is the main difference between SK water ring vacuum pump and 2BV water ring vacuum pump?

- SK vacuum pump is a single-stage water ring vacuum pump, vacuum pump and motor separation, coupled with couplings, vacuum relatively low.

- Q: Working principle and structure of external gear pump

- The principle of the gear pump, gear pump structure consists of two gear mesh together with each other, and composed of pumps known as gear pumps. It relies on the gear teeth meshing space change in volume to transport the liquid, it belongs to the rotary pump, also can be considered as a volume pump. There are many kinds of gear pumps. According to the meshing mode, it can be divided into external gear pump and internal gear pump. According to the tooth shape of gear, it can be divided into positive gear pump, helical gear pump and herringbone gear pump.

- Q: The working principle of magnetic pump

- Working principle of magnetic pumpN of the magnet (n is even) arranged according to the laws in the magnetic clutch assembly inside and outside the magnetic rotor, the magnet part consisting of magnetic coupling system. When the inside and outside the two poles in different relative displacements, two poles between the angle phi = 0, the lowest energy magnetic system; when rotates to the relative displacement is two poles, pole angle between phi = 2 pi /n, the magnetic system of magnetic energy. Remove the external force, due to the magnetic system of magnetic poles repel each other, magnetic magnet will return to the lowest energy state. So magnets in motion, driven by the magnetic rotor.

- Q: Types and differences of pumps

- (I) volumetric typeClassification reciprocating rotary typeThe basic principle of reciprocating action by the piston in the cylinder in the cylinder volume changes again, with the suction and discharge of fluid in the shell or the rotor rotating member rotates, the volume of work between rotor and casing changes to the suction and discharge fluid, such as piston pump gear pump, screw pump(two) blade type;The main structure of vane pumps and fans is rotary, bladed impellers and stationary housings that rotate fluid through the impeller to do work, thereby enabling fluids to obtain energy

- Q: What's the difference between a centrifugal pump and a centrifugal pump? What are they used for?

- As the name suggests, centrifuges are machines that achieve centrifugal effects by centrifugal action. And you say the centrifugal pump is only specific, and the same as the pump

Send your message to us

Small Hydraulic Pump 2CY Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords