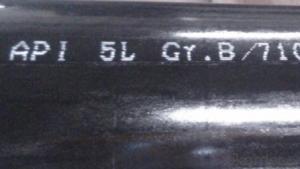

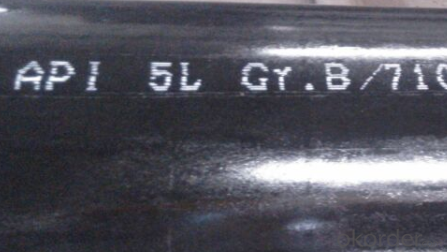

Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

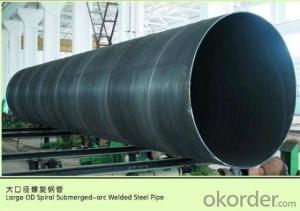

1、Structure of Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | He Bei, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery of Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation:

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 30-45days after received 30%TT |

5、FAQ of Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation Images:

- Q: How are steel pipes used in the power generation industry?

- Steel pipes are extensively used in the power generation industry for various purposes, such as transporting steam, water, and other fluids in power plants. They provide a reliable and durable solution for the high-pressure and high-temperature conditions found in power generation systems. Steel pipes are also used for the construction of boilers, condensers, and heat exchangers, ensuring efficient heat transfer and energy production. Additionally, steel pipes are employed in the exhaust system of power plants to safely and efficiently discharge emissions. Overall, steel pipes play a critical role in the power generation industry by facilitating the transportation of fluids and contributing to the reliable and efficient operation of power plants.

- Q: How do you calculate the pipe head loss for steel pipes?

- The head loss in steel pipes can be calculated using the Darcy-Weisbach equation, which takes into account factors such as the pipe length, diameter, roughness, flow rate, and fluid properties. This equation provides an accurate estimation of the head loss based on these variables.

- Q: What is the flexibility of steel pipes?

- Steel pipes are known for their exceptional flexibility, making them highly versatile and suitable for a wide range of applications. The flexibility of steel pipes refers to their ability to bend and withstand various forms of stress without breaking or deforming. This flexibility is primarily due to the inherent properties of steel, such as its high tensile strength and ductility. Steel pipes can be bent and formed into different shapes without compromising their structural integrity. This allows for easier installation and routing around obstacles, making them more adaptable for complex plumbing or piping systems. Additionally, the flexibility of steel pipes enables them to withstand external forces, such as ground movements or temperature fluctuations, without experiencing significant damage. The flexibility of steel pipes also makes them suitable for applications that require dynamic movement or expansion. For instance, in oil and gas pipelines or in heating and cooling systems, where temperature variations can cause expansion and contraction, steel pipes are able to accommodate these changes without causing leaks or failures. Furthermore, the flexibility of steel pipes contributes to their durability and longevity. The ability to withstand bending and stress helps prevent the formation of cracks or fractures that can lead to leaks or structural failures. This characteristic makes steel pipes a reliable choice for demanding environments, including high-pressure systems or corrosive conditions. In summary, the flexibility of steel pipes is a crucial attribute that allows for easy installation, adaptability to various conditions, and long-term reliability. With their exceptional flexibility, steel pipes are widely preferred in numerous industries and applications where strength, durability, and versatility are essential.

- Q: Can steel pipes be used for structural applications?

- Yes, steel pipes can be used for structural applications.

- Q: What are the factors that affect the lifespan of steel pipes in different environments?

- The factors that affect the lifespan of steel pipes in different environments include the presence of corrosive substances, such as chemicals or saltwater, which can corrode the steel and lead to degradation over time. Other factors include temperature fluctuations, which can cause expansion and contraction of the steel, leading to stress and potential cracking. The quality of the protective coating on the pipes also plays a role, as a strong and durable coating can provide better resistance against corrosion and prolong the lifespan of the pipes. Additionally, the maintenance and regular inspection of the pipes, including cleaning and repairs, can help identify and address any issues early on, preventing further damage and extending their lifespan.

- Q: How are steel pipes used in the construction of dams?

- Steel pipes are commonly used in the construction of dams for various purposes such as water diversion, drainage, and foundation reinforcement. They are used to transport water from one area to another, diverting it away from the construction site or controlling its flow within the dam. Steel pipes are also employed for drainage systems to prevent water accumulation and to ensure the stability of the dam structure. Additionally, they play a crucial role in reinforcing the foundation of the dam, providing strength and support to the overall structure.

- Q: What is the difference between standard wall thickness and extra-strong wall thickness steel pipes?

- Standard wall thickness steel pipes have a thickness that meets the minimum requirements set by industry standards, while extra-strong wall thickness steel pipes have a thicker wall, exceeding the minimum requirements. This difference in wall thickness makes the extra-strong pipes more robust, durable, and able to withstand higher pressure and stress compared to standard wall thickness pipes.

- Q: What are the dimensions of steel pipes?

- Steel pipes can have varying dimensions depending on specific requirements and industry standards. However, they generally adhere to standardized measurements for their outer diameter (OD), wall thickness, and length. The OD of steel pipes can range from small sizes, such as ¼ inch (6.35 mm) or ⅛ inch (3.175 mm), to larger sizes like 48 inches (1219.2 mm) or more for specialty applications. The wall thickness of steel pipes can also vary significantly, ranging from thin pipes with a few millimeters of thickness to thick pipes with several inches of thickness. Regarding length, standard steel pipes are typically produced in lengths of 20 feet (6.1 meters) or 40 feet (12.2 meters). However, custom lengths can also be manufactured to meet specific project requirements. It is important to note that these dimensions are only general examples and may not encompass all potential variations in steel pipe sizes. Therefore, consulting relevant industry standards and specifications is always recommended to determine the precise dimensions necessary for a specific application.

- Q: What are the different standards for steel pipes?

- There are several different standards for steel pipes that are used to ensure quality and compatibility in various applications. Some of the most commonly used standards include: 1. ASTM (American Society for Testing and Materials): ASTM standards are widely used in the United States and provide specifications for various types of steel pipes, including seamless and welded pipes. These standards cover dimensions, mechanical properties, and general requirements for steel pipes. 2. API (American Petroleum Institute): API standards are specifically designed for oil and gas industry applications. These standards provide guidelines for the manufacturing, testing, and inspection of steel pipes used in the oil and gas exploration, production, and transportation sectors. 3. DIN (Deutsches Institut für Normung): DIN standards are widely used in Europe and provide specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards cover dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 4. BS (British Standards): BS standards are widely used in the United Kingdom and cover specifications for steel pipes used in construction, engineering, and other applications. These standards provide guidelines for dimensions, materials, and manufacturing processes for steel pipes. 5. JIS (Japanese Industrial Standards): JIS standards are widely used in Japan and cover specifications for various steel pipe types, including seamless, welded, and cast iron pipes. These standards provide guidelines for dimensions, materials, and technical delivery conditions for steel pipes used in various industries. 6. ISO (International Organization for Standardization): ISO standards are recognized globally and provide specifications for steel pipes used in various industries. These standards cover dimensions, materials, testing, and quality control requirements for steel pipes. It is important to note that different industries and applications may have specific requirements, and therefore, it is essential to refer to the relevant standard for each specific use case. Adhering to these standards ensures the safety, reliability, and compatibility of steel pipes in their respective applications.

- Q: What quota is reserved for buried DN20 steel pipe?

- It is an embedded sleeve control sub item, if the reserved hole, then there is no need to cover, special subject structure adjustment factor of the cost of the water supply and drainage engineering, water supply and drainage engineering he is buried under the charge.

Send your message to us

Slaw Pipe Api 5l Gr. b Used for Oil and Gas Transportation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords