API 5L GR.B SSAW Steel Pipe With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

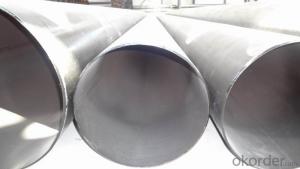

1、Structure of API 5L GR.B SSAW Steel Pipe:

This is Spirally Submerged Arc Welded Steel Pipe.

2、Main Features of the API 5L GR.B SSAW Steel Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、 API 5L GR.B SSAW Steel Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of API 5L GR.B SSAW Steel Pipe :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please feel free to contact us.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Choices happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、 API 5L GR.B SSAW Steel Pipe Images:

- Q: What are the different types of steel coatings used for pipes?

- There are several types of steel coatings used for pipes, including epoxy, polyethylene, polypropylene, and fusion bonded epoxy (FBE) coatings. Each of these coatings provides different levels of corrosion resistance and protection, making them suitable for various applications and environmental conditions.

- Q: How do you determine the required support spacing for steel pipes?

- The required support spacing for steel pipes is determined by considering various factors such as the pipe diameter, material strength, operating conditions, and local building codes and regulations. One of the primary considerations is the pipe's diameter. Larger diameter pipes generally require more frequent support than smaller diameter pipes to prevent excessive deflection and sagging. The material strength of the pipe is also important, as stronger pipes can span longer distances without additional support. The operating conditions of the pipe, such as the fluid being transported and the temperature, can also impact the required support spacing. For example, pipes carrying heavy or corrosive fluids may need more frequent support to prevent excessive stress and potential failure. Local building codes and regulations often provide specific guidelines for the minimum support spacing for steel pipes. These codes may take into account factors such as the pipe diameter, material strength, and operating conditions, as well as safety considerations and structural requirements. In general, it is essential to consult relevant codes, standards, and engineering guidelines to determine the required support spacing for steel pipes accurately. Additionally, working with qualified engineers and professionals experienced in pipe design and installation can ensure that the support spacing meets all necessary requirements and ensures the safe and efficient operation of the piping system.

- Q: How are steel pipes used in the construction of telecommunications towers?

- Steel pipes are commonly used in the construction of telecommunications towers as they provide a strong and durable framework for supporting the tower structure. These pipes are used to create the main mast or tower structure, providing stability and strength to withstand various weather conditions. Additionally, steel pipes are often used for mounting antennas and other equipment on the tower, ensuring secure installation and efficient signal transmission.

- Q: SC15 what does galvanized steel pipe look like?

- Zinc plating: galvanized steel pipe hot galvanized and galvanized two kinds, hot galvanized, zinc coating thickness, with uniform coating, adhesion, long service life and so on. The cost of galvanizing is low, the surface is not very smooth, and the corrosion resistance of itself is much better than that of galvanized pipe. Refer to

- Q: Are steel pipes suitable for use in hydropower plants?

- Yes, steel pipes are suitable for use in hydropower plants. Steel pipes are known for their durability, strength, and longevity, making them ideal for withstanding the high pressures and transporting fluids in hydropower plants. Additionally, steel pipes can effectively handle the flow of water and resist corrosion, making them a reliable choice for hydropower plant applications.

- Q: What are the different types of coatings applied to steel pipes?

- There are several types of coatings that can be applied to steel pipes. Some common ones include fusion-bonded epoxy (FBE) coating, polyethylene (PE) coating, polypropylene (PP) coating, and zinc coating. These coatings serve various purposes such as corrosion protection, insulation, and enhancing the pipe's durability.

- Q: What is the maximum allowable pressure for steel pipes?

- The maximum allowable pressure for steel pipes depends on various factors such as the type of steel used, the diameter and thickness of the pipe, and the specific application or industry requirements. The American Society of Mechanical Engineers (ASME) provides guidelines and standards for pressure vessel and piping design, including the determination of maximum allowable pressure. ASME B31.1 and B31.3 are widely used codes for power piping and process piping respectively. These codes specify the design criteria for various materials, including steel, and provide formulas and charts to calculate the maximum allowable pressure for different pipe sizes and wall thicknesses. The maximum allowable pressure is typically determined based on the pipe's ability to withstand internal pressure without causing any permanent deformation or failure. It is important to note that the maximum allowable pressure for steel pipes may also be influenced by other factors such as temperature, corrosion, and the presence of any external loads or stresses. Therefore, it is essential to consult the relevant codes, standards, and engineering calculations specific to the application to ensure the safe and reliable operation of steel pipes under the given conditions.

- Q: How do steel pipes differ from other types of pipes?

- Steel pipes differ from other types of pipes in a few key ways. Firstly, steel pipes are known for their strength and durability. They have a high resistance to heat, pressure, and corrosion, making them suitable for a wide range of applications. This strength also allows steel pipes to withstand heavy loads and provide a long service life. Another distinguishing feature of steel pipes is their versatility. Steel pipes can be manufactured in various shapes and sizes to meet specific project requirements. This adaptability makes them a popular choice for a wide range of industries, including construction, oil and gas, water treatment, and manufacturing. Steel pipes also offer excellent thermal conductivity, meaning they can efficiently transfer heat from one area to another. This makes them suitable for applications such as heating and cooling systems, as well as for transporting hot fluids or gases. Furthermore, steel pipes are known for their resistance to fire. They have a high melting point and do not easily catch fire or contribute to the spread of flames. This property is crucial in applications where fire safety is a concern, such as in buildings or industrial facilities. Lastly, compared to other types of pipes, steel pipes have a higher initial cost. However, their long-term benefits, such as their durability and low maintenance requirements, often outweigh the initial investment. Steel pipes are also highly recyclable, making them an environmentally friendly choice. In summary, steel pipes stand out from other types of pipes due to their strength, durability, versatility, excellent thermal conductivity, fire resistance, and recyclability. These qualities make steel pipes a preferred option for a wide range of applications in various industries.

- Q: What are the different types of steel pipe bends?

- There are several types of steel pipe bends, including U-bends, J-bends, Miter bends, and Long radius bends. Each type serves a specific purpose and is designed to accommodate different flow requirements in piping systems.

- Q: What are the different wall thicknesses available for steel pipes?

- There are various wall thicknesses available for steel pipes, depending on the specific requirements and applications. Steel pipes come in different schedules, which indicate the wall thickness. The most common wall thicknesses for steel pipes are Schedule 40, Schedule 80, and Schedule 160. Schedule 40 steel pipes have a relatively medium wall thickness and are commonly used for general-purpose applications, such as conveying fluids and gases. They are suitable for low-pressure systems and are widely used in plumbing, HVAC, and irrigation systems. Schedule 80 steel pipes have a thicker wall compared to Schedule 40 pipes and are designed for high-pressure applications. They are commonly used in industrial settings, oil and gas pipelines, and high-pressure fluid transport systems. The increased wall thickness provides higher strength and durability to withstand the pressure. Schedule 160 steel pipes have the thickest wall among the commonly available options. They are designed for extremely high-pressure applications, such as in refineries, chemical plants, and power generation facilities. These pipes provide exceptional strength and can handle the intense pressure and stress found in these industrial environments. Apart from these standard schedules, there are also other wall thicknesses available for specific purposes. For example, extra-strong (XS) pipes have a thicker wall than Schedule 80 pipes and are used for applications that require even higher pressure resistance. It is important to consult with professionals or refer to industry standards to determine the appropriate wall thickness for a specific application. Factors such as fluid or gas pressure, temperature, and environmental conditions should be considered when selecting the appropriate steel pipe with the desired wall thickness.

Send your message to us

API 5L GR.B SSAW Steel Pipe With Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords