SK-4.5D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

SK-DSeries

SK-D series of plastic machinery industry is the ideal vacuum pumps, vacuum pump SK is based on the specific requirements of the plastics industry developed. The suction pump to solve a lot of water in the conditions can not be continuous, severe hard water scaling can not start down a long time and so on. Widely used pipe machine, profiles and other equipment.Items:SK-2D、SK-3D、SK-4.5D、SK-6D,Motor power:4~11KW,extract capacity:2~6(m3/min),Limit vacuum:-0.095MPa.

■List of performance

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

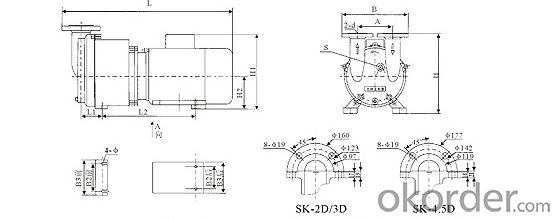

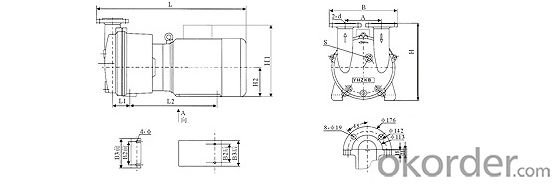

■List of size installation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

■List of size installation

type of pump | L | L1 | L2 | A | B | B2 | B3 | H | H1 | H2 | 2-d | 4-φ | S | ||

Before | After | Before | After | ||||||||||||

SK-6D | 854 | 103 | 481 | 200 | 380 | 300 | 254 | 357 | 315 | 425 | 400 | 160 | φ66 | 16 | G1/2" |

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The diaphragm pump and centrifugal pump refer to the structure of the pump, and the vacuum pump means the use of the pump. There is no comparability between them.Centrifugal is the sign of inertia of an object. As the umbrella turns, water droplets move out of the outer edge of the umbrella and are thrown out. This is what is called centrifugal. Centrifugal pump is designed according to this principle. The high speed rotating impeller blade drives the medium to rotate and is thrown out so as to achieve the purpose of conveying.

- Q: Is the vacuum pump air compressor?

- A vacuum pump is a device or device that uses a mechanical, physical, chemical, or physical chemical method to pump a vacuum from a container to be evacuated. Generally speaking, a vacuum pump is a device that uses various methods to improve, produce, and maintain a vacuum in a confined space.

- Q: What are the starting and stopping procedures for centrifugal pumps?

- Before using the centrifugal pump, the operation instructions of the centrifugal pump shall be read carefully and the specific operation procedures shall be understood so as to make proper use of the centrifugal pump products. The first step is the operation of centrifugal pump inlet valve of centrifugal pump centrifugal pump for all open cavity filled with liquid, close the outlet valve, start the motor, the motor speed is normal, can gradually open the outlet valve, to adjust to the desired condition. Pay attention to self suction centrifugal pump starts to open the exhaust valve, outlet valve should be opened quickly in the normal operation of the motor, to prevent air inlet pipe off caused by cavitation phenomenon produces centrifugal pump, centrifugal pump vibration phenomenon leads to noise of the smoke is not on the water.

- Q: What does electromechanical vector pump mean?

- It is a close set of mechanical and microelectronic technology. It adopts dual control center mode to control, and has a new water pump with logic control center and IPC control center.

- Q: What is the function of the heating pump system for the water pump design?

- Will cause some of the internal friction gap disappeared, the coupling center damage. In this case, starting the pump inevitably results in vibration, friction, etc.

- Q: Difference between pump and compressor

- In the spiral case, the liquid slows down due to the gradual enlargement of the flow passage, and the part of kinetic energy is converted to static pressure, and finally flows into the exhaust pipe at higher pressure and is sent to the required place. When the liquid flows from the center of the impeller to the outer edge, a vacuum is formed at the center of the impeller. As the pressure at the upper level of the tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller. Visible, as long as the impeller continues to rotate, the liquid will continue to be inhaled and discharged.The working principle of the linear pump is different from that of any other pump. It adopts the principle of magnetic suspension and the hydraulic structure of the spiral ring to realize liquid propulsion, that is, to cancel the shaft, to cancel the shaft connection, and to cancel the sealing structure of the shaft. After starting, the electric current is transformed into a magnetic field, and the magnetic field force drives the spiral ring to move, namely, the spiral ring promotes the liquid advance.Compressor (compressor), a driven fluid machine that promotes low-pressure gas as a high pressure gas, is the heart of a refrigeration system. It is of low temperature and low pressure refrigerant gas suction pipe from the suction, through the operation of the motor drives the piston to compress it after high temperature and high pressure refrigerant gas discharge pipe to the exhaust, to provide power for the refrigeration cycle, so as to realize the compression and condensation (exothermic), expansion and evaporation (endothermic) refrigeration cycle.

- Q: What does centrifugal pump mean horizontally?

- Centrifugal pump: centrifugal pump is a centrifugal force on the impeller rotates to transport liquid pump. Centrifugal pumps use the impeller to rotate and cause centrifugal motion of the water to work. The pump before starting to pump shell and the water pipe filled with water, and then start the motor, the pump shaft to drive the impeller and water do high-speed rotation, centrifugal water movement, was thrown to the outer edge of the impeller, the pressure water pipeline flow through the volute pump into the pump shell.

- Q: What is the liquid pump? What are their categories? What are their strengths and weaknesses?

- The liquid pump can be filled with oil, water and chemical medium. The gas drive range of the liquid pump is 1 to 10bar (14.5-145psi). The bottom piston is controlled by a two position four pass pilot valve.

- Q: Direct connection pump What is straight pump and non direct pump? What's the difference in structure?

- What is straight pump and non direct pump? Direct coupled pump shaft and the motor shaft is directly coupled with the coupling and non direct coupled pump: pump shaft and motor shaft through the belt pulley, V-belt connection or other forms of transmission. What is the difference in the structure: the direct coupled pump has the advantages of compact structure, simple installation, but the relatively small power; non direct coupled pump: pump and motor is independent, the two transfer torque through the belt, the structure is relatively large, complex installation, general power is relatively large.

- Q: Pneumatic diaphragm pump compressed air pressure is 4 kg, the discharge pressure is how big?

- Generally slightly lower than 0.4MPa, Zai 0.35Mpa or so, if the outlet is blocked, the outlet pressure will equal 0.4MPa

Send your message to us

SK-4.5D water ring vacuum pump with flange port

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords