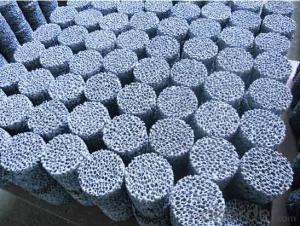

Silicon Carbide Ceramic Filter Plate Series JG-201

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile, Grey Iron, Vermicular Cast Iron and some Iron Alloy,and also for filtrating non-ferrous alloy, such as Cooper alloy and Aluminum alloy. It can remove impurities efficiently, and make metal filling steady in mould. It can also reduce air flow and casting impact in mould, and decrease pin hole, sand hole defeats to increase casting quality and product rate.

JG-202 Silicon Carbide Foam Filter

These series of products are newest products, which are produced through special material formula and latest advanced technology. Compared with normal ceramic foam filters, these new series products can be used at a higher temperature, which have higher strength at room temperature and high temperature. The physical property of this special material enables JG-202 series filters to have a better thermal shock resistance. They are suitable for harsh casting condition, such as placing on the bottom of vertical runner and casting at high temperature.

JG-203 Silicon Carbide Foam Filter

This product is produced through special material formula, and it has good durability, high thermal shock resistance and high porosity. It is mainly applied in filtrating heavy castings and medium-large casting, such as windmill, machine tool, ship parts and large part of mechanical equipment, etc.

Parameters

TypeMaterialsCompressive

Strength (Mpa)Porosity (%)Bulk Density

(g/cm3)Applied Temp.(≤℃)

JG-201SiC≥1.280-900.40-0.551500

JG-202≥1.578-900.45-0.601550

JG-203≥2.078-900.45-0.601500

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- At this time, take the filtrate (this is not the first water slurry) will pollute the ceramic filter pipe, friction ring, filtrate pump, may damage the vacuum system, remaining in the pipeline in the pulp will recoil pressure under the action of pollution caused by the other ceramic plates, ceramic plates blocked him. Once the ceramic plate is broken (depending on the severity), it will make the vacuum distortion, resulting in ceramic filter suction effect worse or even no suction!

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Generally, the vacuum degree of ceramic filter is about -0.08MPa. Sufficient vacuum pressure is only a prerequisite for a good ceramic suction effect. Besides vacuum, the other factors may affect the suction effect:Vacuum display table fault, the difference between the display value and the actual data is great.

- Q: What are the materials that make up the ceramic mold?

- At present, the commercialized porous ceramic membranes are mainly composed of 3 types: flat plate, tubular and multi channel. Flat film is mainly used for small-scale industrial production and laboratory research. The tubular membrane is combined with rice to form a heat exchanger similar to a column tube heat exchanger, which can increase the loading capacity of the membrane, but is gradually withdrawn from industrial application due to its strength problem. The size of the applied ceramic membrane usually adopts a multi channel configuration, that is, a plurality of channels are distributed on a circular cross-section, and the number of general channels is 7, 19 and 37. The main business of the inorganic ceramic membrane preparation technology: using solid particle sintering preparation carrier and microfiltration membrane by sol-gel method in the preparation of ultrafiltration membrane: glass membrane by phase separation method: using special technology (such as chemical vapor deposition, electroless plating, etc.) the preparation of microporous membrane or dense membrane. Its basic theory involves colloid and surface chemistry, material chemistry, solid state ion science, material processing and so on.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: Ceramic filter capacity.

- You ask too general, to say processing capacity (ie capacity), at least to provide material conditions, such as: material name, concentration, particle size distribution. In addition, the basic conditions of equipment operation should be taken into account.

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- There may be a fault filtrate pump, diaphragm pump damage, pump mechanical seal failure, a leak, two is no output or output to the liquid, the pressure is too low, the cleaning effect is not good, the pressure is too large, will cause damage and reduce the concentration of slurry filter plate.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- First, the fineness of the material, resulting in the filter board filter cake moistureTwo, the vacuum can not reach, in the circumstances, whether the vacuum pipe leak

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

Send your message to us

Silicon Carbide Ceramic Filter Plate Series JG-201

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches