Silicon Carbide Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Include:

SiC Foam Filter/CFF-01

Alumina Foam Filter/CFF-02

Zirconia Foam Filter/CFF-03

Magnesium Foam Filter (less used)

Ceramic foam filter is a kind of effective molten metal filter. It’s three-dimensional connected mesh skeleton structure and high porosity makes it has many advantages,large surface area of slags collection,large inner surface area of filtering,Small flow resistance,good filtering effect,etc.

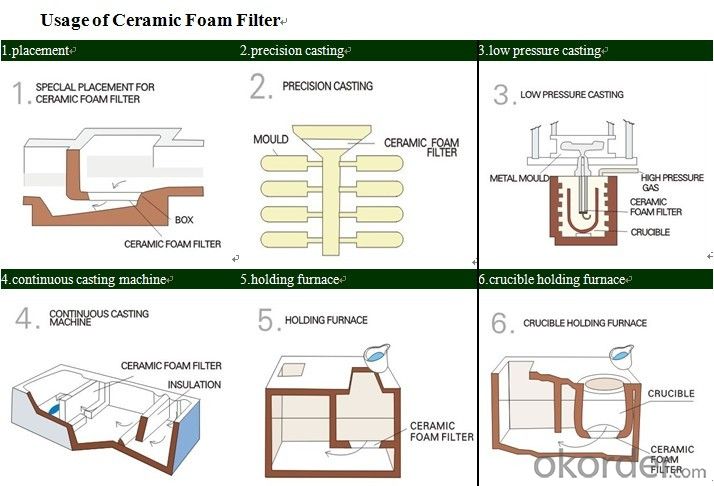

Functions of ceramic foam filter

decontaminate the melting metal liquid,Simplified gating system,Improve casting quality rate,Reduce casting internal re-oxidation defects.Reduce the surface defects after machining of the castings

Physical and Chemical Properties

Material | Alumina | Silicon Carbide | Zirconia | Magnesia |

Color | White | Grey black | Yellow | Dark yellow |

Pore Density | 8-60ppi | 8-60ppi | 8-60ppi | 8-60ppi |

Porosity | 80-90% | 80-90% | 80-90% | 80-90% |

Refractoriness | ≤1100°C | ≤1500°C | ≤1700°C | ≤1000°C |

Bending Strength | >0.6Mpa | >0.8Mpa | >1.0Mpa | >0.6Mpa |

Compression Strength | >0.8Mpa | >0.9Mpa | >1.2Mpa | >0.8Mpa |

Volume-weight | 0.3-0.45g/cm3 | 0.35-0.5 g/cm3 | 0.9-1.5 g/cm3 | 0.35-0.5 g/cm3 |

Thermal shock resistance | 6times/1100°C | 6times/1100°C | 6times/1100°C | 6times/1100°C |

Application | Aluminium , Aluminium alloys and other Non-ferrous alloys | Ductile Cast Iron, Malleable Cast Iron,Gray iron and other Cast Iron | High melting point metal alloys like Steel,AlloySteel,Stainless Steel etc | Magnesium and High-Active Alloy |

For Alumina Casting

Dimensions (mm) | Dimensions (inch) | Pouring Rate (kg/s) | Filtration Capacity (ton) |

178×178×50 | 7×7×2 | 0.2-0.6 | 5 |

228×228×50 | 9×9×2 | 0.3-1.0 | 10 |

305×305×50 | 12×12×2 | 0.8-2.5 | 15 |

381×381×50 | 15×15×2 | 2.2-4.5 | 25 |

430×430×50 | 17×17×2 | 3.0-5.5 | 35 |

508×508×50 | 20×20×2 | 4.0-6.5 | 45 |

585×585×50 | 23×23×2 | 5.0-8.6 | 60 |

For Iron Casting

Dimension (mm) | Pouring Rate (kg/s) | Filtration Capacity (kg) | ||

Grey Iron | Ductile Iron | Grey Iron | Ductile Iron | |

40×40×22 | 4 | 3 | 65 | 32 |

50×50×22 | 6 | 4 | 100 | 52 |

75×50×22 | 9 | 6 | 150 | 75 |

75×75×22 | 14 | 9 | 220 | 100 |

100×50×22 | 12 | 8 | 200 | 100 |

100×75×22 | 18 | 12 | 300 | 150 |

100×100×22 | 25 | 16 | 400 | 200 |

150×150×22 | 50 | 36 | 900 | 450 |

For Steel casting

Dimensi | Zirconia Foam Filter | |

Pouring Rate(kg) | Filtration Capacity(kg) | |

50×50×22 | 3~5 | 30 |

50×75×22 | 4~6 | 40 |

75×75×22 | 7~12 | 60 |

75×100×22 | 8~15 | 80 |

100×100×22 | 14~20 | 100 |

50×22 | 2~6 | 18 |

80×22 | 6~10 | 50 |

90×22 | 8~16 | 70 |

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: The ceramic filter plate is broken. What will happen to the vacuum pump?

- That's a good question. I hope my answer will help you.Ceramic filter ceramic plate broken, nothing more than ceramic plate plug and ceramic plate rupture, you should be the problem of ceramic plate rupture.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The incoming mud content, fine particle size, pulp itself is not suitable for the use of ceramic filter dehydration, if the use of ceramic filter dehydration in this case, will accelerate the blockage of ceramic filter plate, blocking the situation after the second reference description.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Why does not the iron filter of the ceramic filter work?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large?

- The concentration, particle size and mud content of the raw materials are not suitable for or due to changes, which are no longer suitable for dehydration using ceramic filters

- Q: What are the reasons for the program alarm of ceramic filter?

- If that is the ceramic filter tank body of the slurry concentration is diluted, has nothing to do with the ceramic filter itself, can think of ways to enter the ceramic filter tank before the slurry concentration increased, thereby improving the dewatering efficiency of ceramic filter.

- Q: What is the reason that the whole ceramic filter does not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

Send your message to us

Silicon Carbide Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords