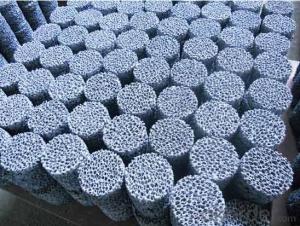

Ceramic Filter Plate - Zirconia/Alumina/Silicon Carbide Foam Ceramic Filter for Alumina Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Zirconia/Alumina/Silicon Carbide Foam Ceramic Filter for Alumina casting

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Application:

For the filtration of molten steel and alloy,large scale iron casting

Product standard:China national GB/T 25139-2010

Zirconia ceramic foam filters are determined for filtering of steel and steel alloys up to the temperature of 1700 °C.

Filters are recommended especially for high quality grades of alloys.

-Drop turbulent of molten steel and alloy

-Improve accepted rate of steel casting

-Reduce foreign matter of steel casting

-Drop twice oxide flaw

-Reduce second-face flaw after machine process

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Other products:

US:

Welcome to visit our factory~

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- In ancient China, filtration technology was applied to produce paper made from plant fibers in 200 bc. The paper method was improved in AD 105. He wandered in dense in papermaking during plant fiber pulp fine bamboo. Water curtain gap filtration, a thin layer of wet pulp stay on the bamboo surface, after drying into paper.

- Q: What filter material are placed in the aquarium filter?

- Generally let off the filter cotton and ceramic rings, there are biochemical balls, coral bone, stone, activated carbon and so onConditional: filter cotton, ceramic ring, biochemical ball, coral bone, stone, activated carbon

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- The shape and mechanism of the ceramic filter are similar to those of the disc vacuum filter, but the filter media are different. The filter medium of ceramic filter is the ceramic filter plate, it can produce the micro capillary effect and capillary force in micropores is higher than the general vacuum applied force, so that the pores keep full of liquid state, so no matter what the circumstances, the air does not pass through the ceramic filter plate, so that the ceramic filter solid-liquid separation of low energy consumption, and high vacuum.

- Q: Influence factors of ceramic filter

- Ceramic filter board, also known as ceramic filter membrane, ceramic plate, ceramic plate, filter plate, etc., is made of corundum, silicon carbide and other special process made of new filter media. At present, as the core component of the ceramic filter, ceramic filter plate has been widely used in solid-liquid separation of iron concentrate, zinc concentrate, sulfur concentrate, copper concentrate, nickel concentrate, molybdenum concentrate, lead concentrate, tungsten concentrate, manganese ore, vanadium ore, aluminum ore, gold ore, non-metallic mine Ore Concentrate Dewatering and coal, chemical industry, papermaking, pharmaceutical, chemical, food, environmental protection and other industries.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: Common troubles of ceramic filter

- (1) low vacuum, can not meet the production requirements. The main reason is the vacuum pipeline leakage, vacuum pump circulating water is not enough, vacuum pump impeller wear and tear, distribution head wear, ceramic filter plate damage, filtrate tank drainage valve is not closed, pulp trough material level is lower;(2) low or fluctuating backwash water pressure. The main reason is the blockage or leakage of the backwash water pipe system and the distribution of head wear;(3) the liquid level of the filtrate tank is high. The main reason is that the circulating water pump impeller or pump shell wear, pressure is insufficient, so that the drain valve can not open or drain valve itself failure, and filter barrels and circulating water pipe between the leakage;

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: What is the backwashing pressure of the ceramic filter?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

Send your message to us

Ceramic Filter Plate - Zirconia/Alumina/Silicon Carbide Foam Ceramic Filter for Alumina Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords