Silica Brick - Refractory Silica Insulation Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

Our silicon insulation brick is made of baked crystalline silica as raw material by adding into compound flammable substance. This product has low thermal conductivity, high refractoriness

under load, residual expansion trace, excellent variability of re-burning line and other characteristics, which is widely available for heat-insulating layer of various high-temperature furnace equipments not in contact with molten slag under high temperature condition (≤1,500 ℃).

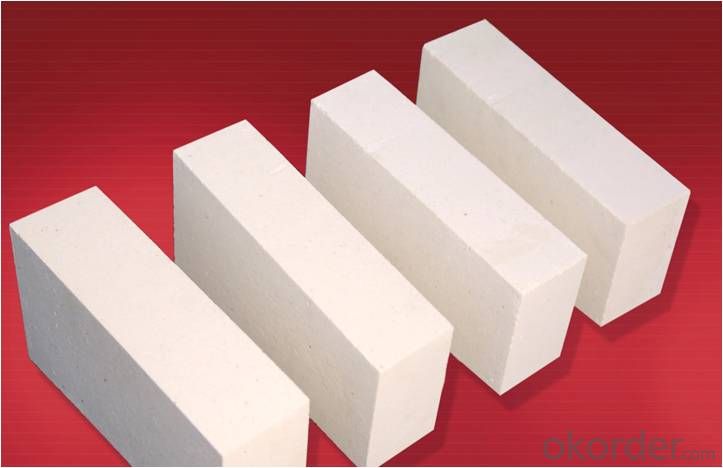

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size.

1) Silicon oxide is above 95%.

2) Good acid erosion resistance.

3) High softening point with temperature.

4) No shrink in burn repeatedly.

5) Temperature of refractoriness under load is above 1650º C

Typical Application

Light- weight Insulating Brick can be used as a hot surface or other refractory refractory insulation support, used for melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other industrial equipment.

Advantage of Insulating Brick

Light- weight Insulating Bricks are made from refractory clay as the main raw material of the AL2O3 content is 30% ~ 48% of the heat insulation refractory brick. The production process adopts the burn out of character and bubble method. With refractory clay, drift beads, refractory clay clinker as raw material, adding binder and sawdust, the ingredients, mixing, molding, drying, firing, volume density was 0.8 to 1.5 g/cm3.

Technical Data

| ITEM | General silica bricks | Hot Air Oven silica bricks | |||||

| GZ-95 | GZ-94 | GZ-93 | Vaults furnace bricks | checker bricks | |||

| SIO2 %Min | 95 | 94 | 93 | 95 | 96 | 95 | 96 |

| Fe2O3 %Max | 1.2 | 1.4 | 1.5 | 1.0 | |||

| Refractoriness °C | 1710 | 1710 | 1690 | 1710 | 1710 | 1710 | 1710 |

| 0.2 Mpa load softening temperature began °C p | 1650 | 1640 | 1620 | 1650 | 1660 | 1650 | 1660 |

| Porosity % | 22 | 23 | 25 | 22 | 22 | 22 | 22 |

| Normal temperature compression strength Mpa p | 29.4 | 24.5 | 19.6 | 35 | 40 | 30 | 35 |

| Bulk Density Min(Kg/m3) | 0.9 | 0.8 | 0.8 | 1.0 | |||

Photos for Workshop

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Brick - Refractory Silica Insulation Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords