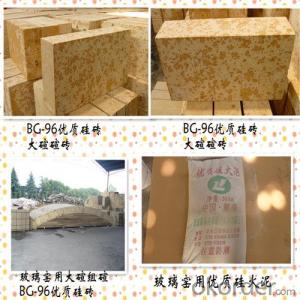

Silica Brick - Refractory Various Silicon Fire Brick Silica Fireproof Block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PHYSICAL AND CHEMICAL PROPERTIES:

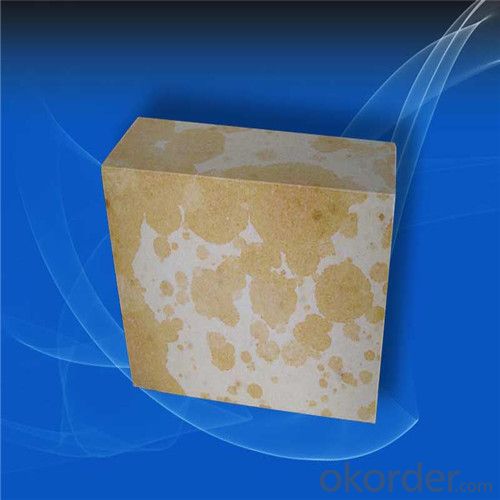

SiO2 content: 94% min

Refractoriness: 1700℃

Apparent porosity 22%max

True density: 2.35g/cm3

APPLICATION:

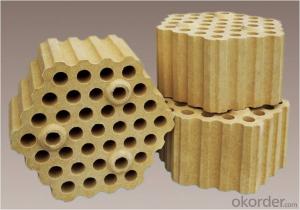

Widely used in coke ovens.

Used in high temperature sections of the checker chamber in hot blast stoves.

Used as low-cost alternative to andalusite and mullite checker bricks in hot blast stoves.

High refractoriness, average thermal shock resistance make it suitable in consistant temperature environment.

General Information of Silica Brick

CMAX silica brick is a kind of acid refractory product which is mainly made of tridymite and cristobalite, and a small amount of quartz and vitreous..

Feature of Silica Brick

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Insulation of hot blast stove, key insulation silica brick hot stove, hot blast stove is shutdown or need repairing in blast furnace.

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: The specific content is what gb/t2608-2012 brick

- Quality assessment procedures, packaging, marking, transport, storage, and quality certificates. Suitable for siliceous refractory bricks.

- Q: What is acid refractory?

- Refractory materials are mainly quartz glass products, combined with fused quartz products, silica brick and unshaped refractories. Semi siliceous refractory materials are generally attributed to this category. As for fireclay refractories, they are also classified as semi acidic or weakly acidic refractories. Also, zircon refractory and silicon carbide refractory for special acidic refractory materials are also classified into this category.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: Brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: Physical solid waste disposal

- Preparation of silica brick pug, a certain amount of waste silica brick used to add ingredients, for the purpose of expansion and stress reduction products when firing, reduce cracks, improve the rate of finished products.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Silica Brick - Refractory Various Silicon Fire Brick Silica Fireproof Block

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords