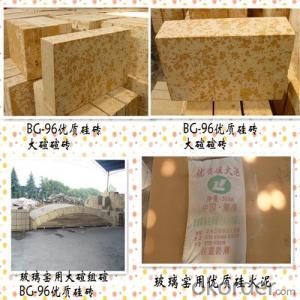

Silica Brick - Fused Silica Refractory Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Good acid and erosion resistance;

2.Widely used for different furnace;

3.Good bonding and structural strength of furnace.

Features:

1.Good acid and erosion resistance, powerful anti high-temperature strength.

2.Soften melting temperature is 1620~1670 °C.

3.Low thermal shock resistance.

4.Natural silica as raw material, plus regular mineralizer.

5.Ensure good bonding and structural strength of furnace.

6.Good heat resistance and long service life.

Application:

1.Glass melting furnace, ceramic frit kiln, sodium silicate furnace, soaking furnace, ceramic kiln, etc

2.Coke oven's coking chamber, combustion chamber walls, steel open-hearth's regenerator and sediment chamber, etc.

3.Load-bearing parts of high temperature hot air furnace and acid open-hearth furnace roof, etc.

Item | Properties | |||

BG-96A | BG-96B | BG-95A | BG-95B | |

SiO2,% | 96 | 96 | 95 | 95 |

Fe2O3 ,% | 0.8 | 1.0 | 1.2 | 1.2 |

Melt index,% Unit weight<20KG Unit weight≥20KG |

0.5 0.6 |

— — |

0.7 0.7 |

— — |

Cold Crushing strength MPa, Unit weight<2KG Unit weight≥20KG |

35(30) 30(25) | |||

Softening temperature under load,°C | 1680 | 1670 | 1660 | 1650 |

Apparent porosity % | 22(24) | |||

Bulk density,g/cm3 | 1.85-1.9 | |||

True density,g/cm3 | 2.34 | 2.35 | ||

Application | sodium silicate furnace,ceramic frit furnace ,glass furnace,coking furnace, metallurgical furnace and other furnaces | |||

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Acidic materialMainly siliceous materials, such as quartz, tridymite and cristobalite, chalcedony, flint, opal, white quartzite, silica sand, diatomaceous earth, silicon oxide contained in these siliceous materials (SiO2) at least 90%, pure raw materials are silicon oxide as high as 99% or more. Siliceous materials at high temperature is the acidic nature of chemical dynamics, when the presence of metal oxide, or when in contact with the chemical reaction, and combined with a fusible silicate. Therefore, if there is a small amount of metal oxide in siliceous material, it will seriously affect its thermal resistance.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The use of high thermal conductivity of silica brick, reducing coke fuel consumption, reduce emissions of pollutants such as NOx, with considerable economic benefits and social benefits, is the future direction of the new technology of using coke oven refractory.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: What are the main constituents of refractory bricks?

- Clay brick and clay brick are mainly composed of mullite (25% ~ 50%), glass phase (25% ~ 60%) and square quartz and quartz (up to 30%). Usually with hard clay as raw material, pre calcined mature material, and then with soft clay, semi dry or plastic molding, the temperature at 1300~1400 C fired clay brick products. Can also be added a small amount of water, glass, cement and other binders to make non burning products and amorphous materials. It is a refractory brick commonly used in blast furnaces, hot blast furnaces, heating furnaces, power boilers, lime kilns, rotary kilns, ceramics and refractory bricks.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Brick - Fused Silica Refractory Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords