Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Other |

| SiO2 Content (%): | 91 | MgO Content (%): | 0 | CaO Content (%): | 0 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 | SiC Content (%): | 0 |

| Model Number: | QG1.2 | Brand Name: | sunrise | size: | any size |

Packaging & Delivery

| Packaging Details: | wooden pallet |

| Delivery Detail: | 2 months |

Specifications

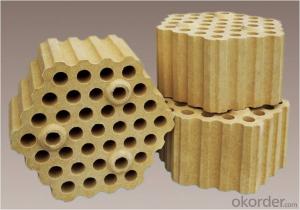

light weight fused silica refractory for hot blast furnace

1)Good acid erosion resistance.

2) High softening point with temp

light weight fused silica refractory for hot blast furnace

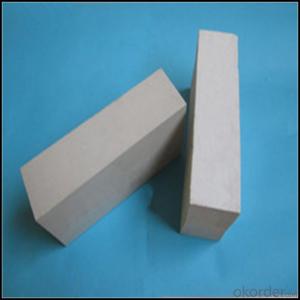

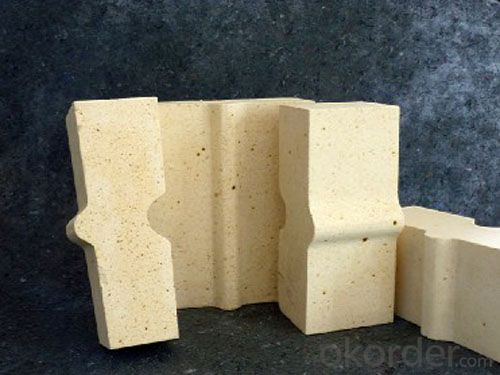

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size

1)Good acid erosion resistance.

2) High softening point with temperature.

3) No shrink in burn repeatedly.

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products

Item Brand Index | Light weight silica brick |

QG-1.2 | |

SiO2≥ | 91 |

Refractoriness | 1670 |

RUL(0.2 MPa)T1, °C | 1560 |

Apparent Porosity%≤ | ≥45 |

Cold Crushing Strength Mpa ≥ | 3.5 |

True Density g/cm3 ≤ | 2.39 |

Bulk Density g/cm3 ≤ | 1.20 |

Our factory product various kinds of refractory products. The products can be made according with the customers' requirement

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

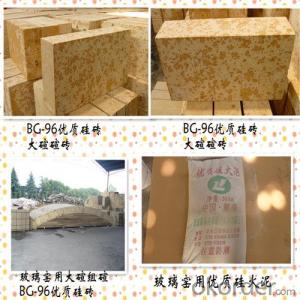

- Q: The introduction of silica brick

- Brick refers to the content of more than 93% products SiO2. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system. The higher the content of SiO2 in silica raw material, the higher the refractoriness of the product. According to the use of brick varieties, divided into: coke oven silica brick, brick for hot blast stove, electric stove with brick, brick for glass furnaces. According to the transformation is divided into: standard bricks, tiles, bricks and general special brick etc..

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: Semisilica brick, clay brick, high alumina brick and what is the difference?

- This is a kind of refractory material is divided into three types: semisilica brick (A12O315 ~ 30%), clay brick (A12O330 ~ 48%), high aluminum brick (A12O3>48%).

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Why in the production of the brick to detect the volume density

- Fast density test, please consult an instrument.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

Send your message to us

Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords