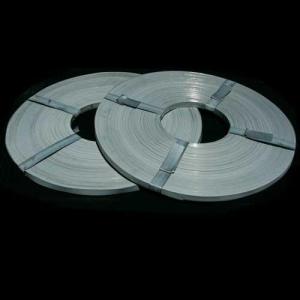

Silane Cross-linkable PE Compound for 10KV and Below Cable Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Grade 4214/4214B is suitable for 10kv and below medium and low voltage cable, it is composed by 95% silane crosslinkable low density polyethylene (compound A) and 5% catalyst (compound B). The main raw materials of the product are cable-use high-purity LDPE compound with mature graft technique and low impurity content, the product’s major characteristics are

◆The product is suitable for the extrusion method of squeezing extrusion,half-tubing extrusion and tubing extrusion.

◆Cables made from the product have excellent performance in smooth cablesurface, high extrusion speed and production efficiency.

◆Extremely low impurity content and excellent electric performance.

Standard

After crosslinked in the tepid water, the cable made from the product grade 4214/4214B can comply with the standard of IEC60502-2004,GB/T12706-2002.

Main Properties & Typical Values

Test items | Test method | Unit | Standard | Typical value |

Tensile strength | GB/T1040.3 | MPa | ≥14.0 | 21.5 |

Elongation at break | GB/T1040.3 | % | ≥350 | 480 |

Heat ageing properties (Test temperature 135℃, 168hr) Maximum tensile strength change Maximum elongation at break change | GB/T8815 |

% % |

±20 ±20 |

7.0 5.2 |

Heat elongation (200±3)℃x15minx0.2MPa) Maximum elongation change under load Maximum permanent elongation change after cooled | GB/T2951 |

% % |

≤80 ≤5 |

46 -4 |

Impact brittle temp. (-76℃) | GB/T5470 | --- | ≤15/30 | Pass* |

Dielectric Strength | GB/T1408.1 | MV/m | ≥35 | 39* |

Dielectric loss factor 50Hz, 20℃ | GB/T1409 | --- | ≤1×10-3 | 7×10-4* |

Dielectric constant 50Hz, 20℃ | GB/T1409 | --- | ≤2.35 | 2.25* |

Volume resistance (20℃) | GB/T1410 | Ω.m | ≥1.0×1014 | 5×1014* |

Typical values were tested on the 1mm sample strip by squeezing film extrusion after mixing compound of A & B (at percentage of95:5) and be boiled in 90℃ water for four hours.

*Especially, these typical values were tested by press moulding sample under the condition of 180±2 ℃, 15min, and pressure over 15Mpa, then boiled in 90℃ water for four hours.

Recommended Processing Technique

1. Extrusion Equipment

Most extruders for PVC and PE suit for 4214/4214B.

The recommended equipment and processing technique is as following.

Ratio of length and diameter 18—25:1

Diameter 45—120mm

Ratio of compressing 1.5—3.5

Ratio of elongation 1:1.0—1:1.5

Filtering mesh 40/60/40

2. Extruder processing temperature and other related settings

Temperature Setting: Specific processing temperature should be based on different equipment and pressing conditions, reference settings are as following:

Feeding section(℃) | Compression Section(℃) | Measurement Section (℃) | Die head and Mould (℃) |

150~165 | 165~175 | 175~190 | 190~200 |

Die head setting: Squeezing extrusion style, half-tubing extrusion style and tubing extrusion style

Cooling water temperature: Should not be less than 25℃,gradual cooling water tank is recommended.

3. Crosslink

After extrusion and cooling, the cable can be crosslinked by immersed in hot water (90℃) or exposed in low pressure vapour. The time required for crosslink is based on the thickness of the insulation and the coil size, the thicker the insulation and the greater the coil size, the longer the crosslink time required. The crosslink time can be calculated according to the equation of 4hr/mm for 90℃.

- Q: I would like to ask my new workshop power consumption of about 500KW, injection molding machine, 60KW . 40KW . 20KW . the other 20KW, how much should the wire? Respectively how to use lines and switches more

- A very practical proposal: to your local talent market, a large job fairs, and the best and your professional relevance, to see, look at what positions, pay how? You can also chat with hr, you will understand.

- Q: Ipad not charge how the matter. Said the cable or accessories have not been certified, and may not be able to cooperate with this ipad reliable work....

- According to the "Power Engineering Cable Design Code" GB-. 5.3.3 only asked for the depth of the cable buried directly: drop the blue skin to the ground depth, not less than 0.7 meters; when located in the roadway or farmland Under the appropriate should be deepened, and should not be less than 1.0 meters. 5.4.3 protected pipe buried in the ground, should meet the requirements under the depth of the pressure and environmental corrosion resistance. Through the uneven settlement of the backfill section and other places to increase the force, it is appropriate to use steel. Another direct burial should be selected armor type.

- Q: Remove the computer and wash it off. What the motherboard did not move it, that is, the dust of those dust sasses, as well as the other wire of the skin what Sassafras wash, but the computer re-connected to the Internet when the old mistakes . and the lower right corner of the red Fork appears, disappeared after the emergence. The The Said the network cable is not plugged in, but the MODERN that POWER, LINK, LINE, 3 lights are normal display. The The This is how the matter, and just also appeared keyboard and mouse just start the machine can also be used normally, but in a moment to fall, and then plug their plug re-plug the mouse lights can be displayed, but the lights on the keyboard simply do not Bright, restart the computer but good, what is going on? bother. The The I hope the master quickly to help me, and this machine is relatively old ah No problem added: on a machine, just tried to re-create a connection in the network neighborhood, useless more

- No need. Galvanized flat iron to do when the grounding grid is not anti-corrosion, but if there is welding or damaged place to become anti-corrosion.

- Q: Rt, the charger did not change, has been no problem before, today just plugged into the charger, the results appear as if the problem, before the out of this problem, and now only ipad power off after the power can not be charged, and ipad start , Then immediately prompted the title, can not charge more

- At the same time, security monitoring line itself is a weak line

- Q: IPhone mobile phone data cable can not charge the power, the above shows the cable or accessories not certified can not work with the iPhone,

- Not allowed to slot the proposal with PVC gusset which is only 1 cm thick only open protective layer on it! The water pipe is not enough unless you have a thickened wall outside the decoration.

- Q: Wire and cable CCC product consistency is what

- What brand of wire pipe PVC pipe used? Is not in the financial or plastic surgery better ah? Guiqiu we recommend, thank you! What brand of network cable used a good, need double shielded cable, thank you

- Q: What is the difference between "wire" and "cable"?

- Simple point, the plotter is generally used to out of the line map, the general is the Academy of Engineering, the Bureau of the use of a CAD map, and some can also be some effect of the general effect of the map, generally suitable for color requirements are not very high, but right Print accuracy requires a high place. Inkjet machine can be divided into indoor and outdoor ink, outdoor irritating smell, for outdoor advertising like the effect of the map, the indoor no irritating smell, the general subway, as well as other indoor advertising are used this out of

- Q: Apple 6 Charging Why always show this cable has not yet been certified

- Cable and cable distinction In fact, "wire" and "cable" and there is no strict boundaries

- Q: What are the varieties of wire and cable (detailed point)

- (The difference between the two cables: WDZ and WDZC are the combustion characteristics of the cable, both halogen-free low smoke flame retardant cable, but the former is a single vertical flame retardant test, which is bundled combustion C class flame retardant Test, but the flame retardant performance requirements are not the same. The meaning of the letter: W refers to the halogen-free; D refers to the low smoke; Z refers to the flame retardant WDZ is halogen-free low smoke flame retardant jacket power cable. WDZC refers to halogen-free low smoke C-class flame retardant reference )

- Q: Wire and cable fire resistance to meet what standards, which can provide about, thank you!

- Replaced with 30 * 30 PVC flameproof trough, side wiring side cover.

Send your message to us

Silane Cross-linkable PE Compound for 10KV and Below Cable Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches