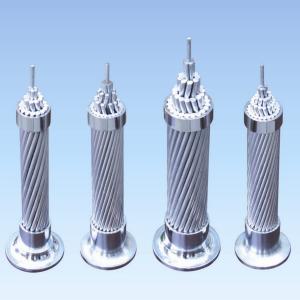

Black Silane XLPE Compound for 10KV and Below Aerial Hanging Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Grade 4215 is specially used for 10KV below aerial hanging power cable, it is composed by 90% silane crosslinkable low density polyethylene (compound A) and 10% black catalyst (compound B). The product has outstanding performance in anti-ageing property, wild processing temperature,easy processing characteristics and excellent product quality.

Standard

After crosslinked in the tepid water, the cable made from the product grade 4215 can comply with the standard of IEC60502-2004, GB/T14049-2008.

Main Properties & Typical Values

Test Items | Unit | Test Method | Standard | Typical value |

Tensile strength | MPa | GB/T1040.3 | ≥13.5 | 19.0 |

Elongation at break | % | GB/T1040.3 | ≥300 | 460 |

Heat ageing properties (Test temperature 135℃, 168hr) Maximum tensile strength change Maximum elongation at break change |

% % | GB/T8815 |

±20 ±20 |

7.2 6.0 |

Heat elongation (200±3)℃x15minx0.2MPa) Maximum elongation change under load Maximum permanent elongation change after cooled |

% % | GB/T2951 |

≤80 ≤5 |

60 2 |

Impact brittle temp. (-76℃) Impact brittle | Failure no. | GB/T5470 | ≤15/30 | pass* |

Dielectric Strength | MV/m | GB/T1408.1 | ≥30 | 37* |

Dielectric loss factor 50Hz, 20℃ | -- | GB/T1409 | ≤1×10-4 | 1×10-4* |

Dielectric constant 50Hz, 20℃ | -- | GB/T1409 | ≤2.35 | 2.2* |

Volume resistance (20℃) | Ω·m | GB/T1410 | ≥1.0×1014 | 1×1014* |

Pressure crack test F50 | hr | GB/T2951 | 1000 | pass* |

Artificial atmosphere ageing properties: Ageing After 42days, Maximum tensile strength change Maximum elongation at break change Ageing after 42days vs. after 21days Maximum tensile strength change Maximum elongation at break change |

% %

% % | GB/T14049 |

±30 ±30

±15 ±15 |

-15 -20

-10 -11 |

Typical values 1-4, 11 were tested on the sample strip by squeezing film extrusion after mixing compound of A & B (at percentage of 90:10) and be boiled in hot water at 90℃ for 4 hours.

*Especially, these typical values were tested by press moulding sample (A and B mixed atpercentage of 90:10), under the condition of 180±2 ℃, 15min, and pressure over 15Mpa, then boiled in 90℃ water for four hours.

Recommended Processing Technique

1. Extrusion Equipment

Most extruders for PVC and PE suit for 4215

The recommended equipment and processing technique is as following.

Ratio of length and diameter 18—25:1

Diameter 45—120mm

Ratio of compressing 1.5—3.5

Ratio of elongation 1:1.0—1:1.5

Filtering mesh 40/60/40

2. Extruder processing temperature and other related settings

Temperature Setting: Specific processing temperature should be based on different equipment and pressing conditions, reference settings are as following:

Feeding Section(℃) | Compression Section(℃) | Measurement Section (℃) | Die head and Mould (℃) |

150~165 | 165~177 | 175~190 | 190~200 |

Die head setting: Squeezing extrusion style and tubing extrusion style

Cooling water temperature: Should not be less than 25℃, when using tubing style extrusion method, gradual cooling water tank is recommended for better control the heat shrinkage.

3. Crosslink

After extrusion and cooling, the cable can be crosslinked by immersed in hot water (90℃) or exposed in low pressure vapour. The time required for crosslink is based on the thickness of the insulation and the coil size, the thicker the insulation and the greater the coil size, the longer the crosslink time required. The crosslink time can be calculated according to the equation of 4hr/mm for 90℃.

- Q: Four lines only reached a phase line, at the other end all charged, I use the digital pen! In addition, I often check the cable when the cable current through the dot digital pen voltage symbols sometimes have time to disappear, in other bare wires when the test keys are normal! What is this going on! Ask the heroes to give the younger brother a complete point of the answer! More

- There are [the top of the machine can be broken off the ball can be hit by Jiu turtle snow box video output cable and DVD video output line] into a junction box, and then through the sub-box toggle switch to select the 'set-top box' or 'DVD'; This junction box outputs a wire connection device or is connected to a TV.

- Q: Rt, the charger did not change, has been no problem before, today just plugged into the charger, the results appear as if the problem, before the out of this problem, and now only ipad power off after the power can not be charged, and ipad start , Then immediately prompted the title, can not charge more

- The proportion of the cross-sectional area of the cable through the embedded pipe is 20%

- Q: IPhone mobile phone data cable can not charge the power, the above shows the cable or accessories not certified can not work with the iPhone,

- Wiring room refers to the distribution of the weak floor of the room, the weak point refers to the building weak vertical pipe

- Q: Cable a fire line power and why the other did not pick up the line with a pen test also have electricity? Answer detailed point

- Megohmmeter, such as measuring insulation normal, that is, induction power, the other line after grounding, the pen measured no electricity.

- Q: Apple mobile phone does not support this charge when charging this thing how to charge

- Charging line and the phone does not match, for the good point of the line just fine

- Q: What is the difference between "wire" and "cable"?

- Inkjet printer is not printed, pictorial machine high definition, generally used in the advertising industry, for large outdoor advertising, the nozzle can choose not necessarily the number of installed, the more spray, spray the faster, a nozzle of the general life 1 year.

- Q: IPhone6 This cable or accessories have not been certified how to solve

- The color is easy to distinguish. General yellow on behalf of the video line, red white plug left and right audio.

- Q: Wire and cable model ZD what does it mean

- Wire pipe water problem: In fact, this problem is very serious, then this line should be scrapped or replaced, if you continue to reluctantly use not only to bring you the safety of trouble and the insulation of the wire dropped sharply! Because there is water it will lead to internal leakage can also make the wire heat caused by wire burning and trivial trivial accident, so be sure to take the necessary replacement! Supplement: the wire out of all, with the wire to grab the absorbent gauze and the like back to the twitching, many times for the gauze to dry the water, hair dryer toward the tube to heat the tube to dry and then re-layout of the new line.

- Q: What are the varieties of wire and cable (detailed point)

- (The difference between the two cables: WDZ and WDZC are the combustion characteristics of the cable, both halogen-free low smoke flame retardant cable, but the former is a single vertical flame retardant test, which is bundled combustion C class flame retardant Test, but the flame retardant performance requirements are not the same. The meaning of the letter: W refers to the halogen-free; D refers to the low smoke; Z refers to the flame retardant WDZ is halogen-free low smoke flame retardant jacket power cable. WDZC refers to halogen-free low smoke C-class flame retardant reference )

- Q: What is the difference between the WDZ wire and cable, the ZR wire cable and the NH wire and cable, and what kind of wire and cable should be used?

- BV1 * 2.5 is a 2.5 square line. 2 * 2.5 is two 2.5 square lines. 3 * 2.5 is three 2.5 square lines. 4 * 2.5 is the 4 2.5 square line lighting wire power cord with 2 * 2.5. Light wire with 1.5 is enough. Socket (pipe) with three 2.5 square lines, you can also use 3 * 2.5 a. 4 * 2.5 for three-phase motors.

Send your message to us

Black Silane XLPE Compound for 10KV and Below Aerial Hanging Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000kgs kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches