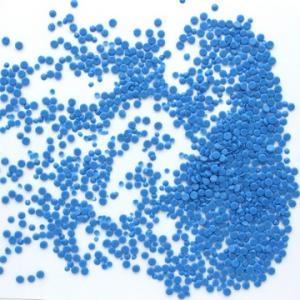

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant EPDM Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

epdm rubber cable:

1, 30-year professional manufacturer

2, low-smoke, halogen-free, flame retardant

3, UL and CM grade

epdm rubber cable:

1. Type and application

Type | Product | Application and Cable Specification |

GDWE1125 | 125 degree C Silane Cross-linkable Low Smoke Halogen Free Flame Retardant EPDM Compound | Used as insulation for low voltage cables, flexible cables, and rubber insulation and jacket for 105 degree C and 125 degree C cross-linkable low smoke halogen free cables Work temperature: -40 to 125 degree C |

GYJE-20 | Silane Cross-linkable EPDM Insulating Compound | Used as rubber insulation for 15 to 20 KV cables and flexible cables, and rubber insulation and jacket for 70 degree C to 125 degree C cables Work temperature: -40 to 125 degree C |

GYJE-10 | Silane Cross-linkable EPDM Insulating Compound | Used as rubber insulation for less than 10 KV cables and flexible cables, and rubber insulation and jacket for 70 degree C to 125 degree C cables Work temperature: -40 to 125 degree C |

2. Description

Silane cross-linkable EPDM rubber compound, based on EPDM and other copolymer, is produced and pelletized by special technology, adding some flame retardant, initiating agent, cross-linking agent, and some other suitable additives. This compound contains two parts A and B, which should be mixed according to suitable proportion when used. This compound has well performance of processing easily, physical properties, and cost advantage with low density.

3. Processing

The following temperature(℃) profile of extruder is recommended:

Type | Proportion of A and B | Processing Equipment | Compression ratio | L/D | Processing temp. | Cross-linkable conditions | |||||

Z 1 | Z2 | Z3 | Z4 | Head | Die | ||||||

GDWE1125 | 90:10 | It is better to use professional extruder for halogen free compound. If you use PVC extruder, the speed should be lower, reinforce cooling | 1.2~1.5:1 | 25:1~ 18:1 | 100 | 140 | 160 | 160 | 165 | 170 | Hot water or steam, based on the terms of more than 85℃, 4h/mm thickness cross-linking speed |

GYJE-20 GYJE-10 | 97:3 | Conventional PVC extruder | 2.5:1~3.5:1 | 25:1 | 110~170℃ | 180-190℃ | |||||

method of application:

1. When you use this product, please mix A and B before put into the hopper. If you need color, the cable factory can use the polyvinylene masterbatch. The material should be used up in 8 hours after being opened and the rest can be resealed and usable within 24 hours.

2. The extruder should be cleaned after stopping with PVC material, (It is preferable if you can take apart the screws to clean.)

3. The silane cross-linkable LSZH compound should not be stayed in the extruder for a long time .If it stayed for long time, it will pre-crosslink after open the machine, which will make lumps in the surface of cable. It need to be discharged all the pre cross-linker, and then produce the cable properly.

4. To ensure the safety and fully of the cross-linking, when immersed the compound into the hot water or steam, please calculate the cross-linking time based on the terms of more than 85℃, 8h/mm thickness cross-linking speed.

5. At room temperature, the degree of cross-linking can also meet requirements after 4-10 days. The specific time can be different according to the temperature and humidity.

Note:

1. Transportation: avoid direct sunlight and weathering and machine damage

2. Convey: discharge softly, put off softly, avoid from the bursting by the stressed with the aluminum-plastic Bag.

3. Storage: it can not be landing stack. It should be put on the pallet in the clean dry storage.

4. Keep dry: When the material used, it must not be contained the outer water. Otherwise, it will seriously pre-crosslink.

5. Quality guarantee period: 6 months after manufacturing.

4. Storage and transport

Packaging:Vacuum Aluminum foil and PE membrane inside bag, and kraft outside bag.

Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated.

5. Properties

Note: The below data is got after the compound boiled in 80 degree C water 4 hours. Natural crosslink can also be finished at proper temperature and in proper time.

NO. | Item | Units | GDWE1125 | GYJE-20 | GYJE-10 | |||

Standard Vaule | Typical Value | Standard Vaule | Typical Value | Standard Vaule | Typical Value | |||

1 | Density | g/cm3 | — | 1.35 |

| 0.9 |

| 0.88 |

2 | Tensile Strength | MPa | ≥10 | 12.0 | ≥16 | 23.0 | ≥16 | 21.0 |

3 | Elongation at break | % | ≥150 | 250 | ≥300 | 530 | ≥300 | 540 |

4 | Hardness | Shore A | — | 90 |

| 90 |

| 70 |

5 | Thermal aging |

|

|

|

|

|

|

|

Conditions: temperature | 158℃ |

|

|

|

|

|

| |

time | 168h |

|

|

|

|

|

| |

TS retention | % | ≤±30 | -11 | ≤±30 | -6 | ≤±30 | -8 | |

EB retention | % | ≤±30 | -10 | ≤±30 | -8 | ≤±30 | -7 | |

6 | Thermal prolongation |

|

|

|

|

|

|

|

200℃,0.2MPa,15min |

|

|

|

|

|

|

| |

Elongation under load | % | ≤175 | 80 | ≤175 | 70 | ≤175 | 70 | |

Permanent deformation | % | ≤15 | 0 | ≤15 | 0 | ≤15 | 0 | |

7 | Volume Resistivity | Ω·m | ≥1.0×1012 | 2.3×1013 | ≥1.0×1013 | 1.0×1014 | ≥1.0×1013 | 1.0×1014 |

8 | Dielectric Strength | MV/m | ≥20 | 28 | ≥25 | 35 | ≥25 | 32 |

9 | Resistance to thermal stress crack | h | ≥96 | pass |

|

|

|

|

10 | Resistance to environment stress crack | h | ≥96 | pass |

|

|

|

|

11 | Oxygen Index |

| ≥30 | 30 |

|

|

|

|

12 | Smoke density Flaming |

| ≤100 | 60 |

|

|

|

|

Non flaming |

| — | 180 |

|

|

|

| |

13 | Burst size of HCL | mg/g | ≤5 | 0 |

|

|

|

|

14 | PH Value |

| ≥4.3 | 5.6 |

|

|

|

|

15 | Conductivity | μS/mm | ≤10 | 0.6 |

|

|

|

|

16 | Toxicity Index |

| ≤5 | 1 |

|

|

|

|

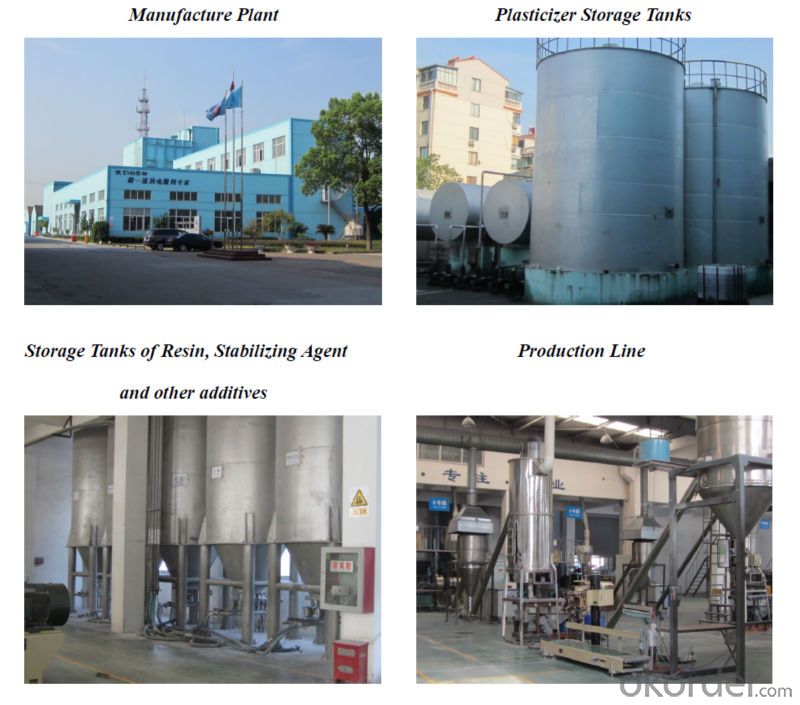

6, Company Pictures of epdm rubber cable

- Q: What are the raw materials of foam plastics and how do they come out?

- More bisphenol A epoxy resin, epoxy value of 0.51 ~ 0.22mol/100g. When the viscosity is 25 degrees centigrade, it is 20Pa / S; the viscosity is 130 s at 1Pa.

- Q: What material is best for plastic gears?

- At present, the demand for plastic gear with high wear resistance and noiseless gear is very strong. POLYMSJ noiseless nylon composite occupies a leading position in this field. If it doesn't solve the problem, you can try it out.

- Q: What is the hardness of PAEK+30%GF plastic material?

- Mohs hardness is mainly used in mineral classification. The Mohs scale from I to 10. the scratch resistance increasing (such as talc Mohs hardness is I, the diamond is 10), namely each scale corresponding to the Mohs material can be scraped traces in the previous stage of material. According to the Mohs hardness can determine the scratch resistance between contact with objects in the use of Engineering plastics.Engineering plastics Mohs hardness is between 2 and 3.

- Q: What are the raw materials for plastic products? Resin or oil?

- Plastic is a kind of macromolecule organic material with resin as its main component. It can form a definite shape at a certain temperature and pressure and maintain a definite shape at normal temperature.Usually refers to the resin conversion or melting range when heated into force with mobility, at room temperature is organic polymer solid or semi-solid or liquid plastic, it is the most basic and most important components. Broadly speaking, in the plastics industry, any polymer used as a basic material for plastics can be called resins.

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water). In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water. PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"". PP products are light, tough and chemical resistant.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: What are the raw materials for vest plastic bags?

- Low density polyethylene (PE), or LDPE, is the most widely used plastic packaging and printing industry in many countries. The specific gravity is 0.92 ~ 0.93, and can float in water. Low crystallinity (60%), under the pressure of 1000 ~ 3000kg/C square meters of bulk polymerization of high pressure polyethylene. At 23 degrees centigrade, the density is about 0.92. It is difficult to roll forming and is suitable for tubular films. Applicable to food packaging, fiber packaging, daily necessities packaging.

- Q: ABS plastic storage conditions

- Plastic materials generally react with light and oxygen for a long time to become yellow and brittle

- Q: What are the raw materials needed for producing plastic hair dryer shell and flashlight shell?

- PA nylon as a large amount of Engineering plastics. Widely used in machinery, electrical appliances, textile equipment, chemical equipment, aviation and other fields. Become an indispensable structural material in all walks of life, the main features are as follows:1. excellent mechanical properties. High mechanical strength and good toughness.2. excellent heat resistance. Such as nylon 46, high crystallinity Nylon high thermal deformation temperature, can be used at 150 degrees Celsius for a long time. PA66 after glass fiber reinforcement, its thermal deformation temperature above 250 degrees celsius.3. excellent electrical insulation performance. Nylon has high volume resistance and high breakdown resistance. It is an excellent insulating material for electrical and electrical equipment.4. self lubrication, good friction resistance. Nylon has a good self lubrication, small friction coefficient, so as to drive parts, long service life.5. excellent weather resistance.

- Q: What two ingredients fit together to solidify like plastic?

- What is the material of plastics? This is important because even the adhesive with high bond strength can not be well adhered to on some surfaces, such as PTFE.

- Q: What are the criteria for the classification of plastic materials at injection molding and extrusion?

- In comparison, the lower melt flow rate is applicable to the extrusion grade, and the higher is applicable to the injection molding grade. As to what is low and what is high, there is a difference between the different plastic varieties.

Send your message to us

Silane Cross-linkable Low Smoke Zero Halogen Flame Retardant EPDM Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches