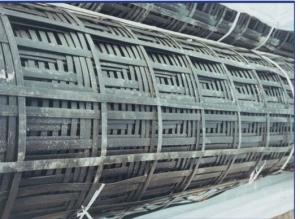

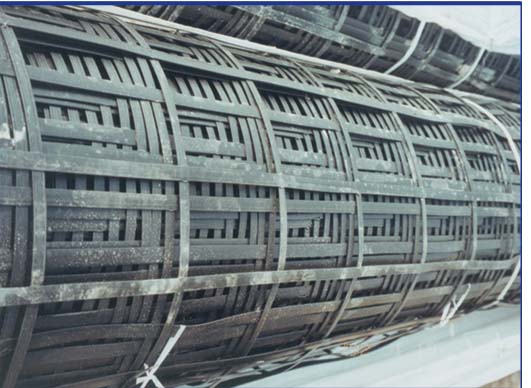

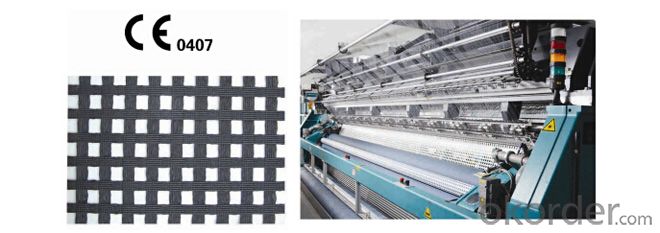

Shandong Embellish Warp-Knitted Geogrids for Roads

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Warp-Knitted Geogrids

Polyester geogrid high strength fiber (polyester warp knitting polyester geogrid, polyester geogrid), USES the high strength sea black silk ribbon industry filament grid cloth after the warp knitting direction detection, the coating is processed into geogrid. Used in soft soil project and ground treatment and roadbed, dike reinforcement enhancements, reduce the project cost in order to improve the construction quality.

Polyester geogrid product application:

1, highway, railway, municipal roads and other road soft soil roadbed reinforcement enhancements, can effectively improve the strength of subgrade, delay the reflective crack of road.

2, dam in hydraulic engineering, river of reinforcement, isolation, strengthening soft soil foundation, strengthen its protection ability, improve the bearing capacity and stability of the foundation.

3, used for reinforced embankment slope, retaining wall reinforcement, enhance the overall strength.

Polyester geogrid features:

High tensile strength, tensile strength, with the soil crushed stone binding force strong.

Product specifications and performance parameters (the warp knitting polyester geogrid standard

Performance specifications 20 D - D - 20-30 D - 30-40 D - 40-50-50-80 - D - 80 - D - 100-100

Elongation % 10% - 15%

Intensity (KN/m) longitudinal 20 30 to 40 to 50, 80, 100

Transverse 20 30 to 40 to 50, 80, 100

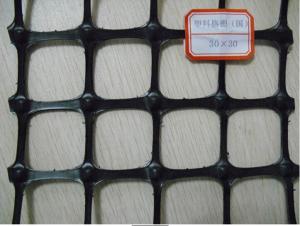

The grid (12.5 x 12.5 x 12.7 12.5 mm) 25 x 25 25.4 x 25.4 x 25.7 25.4 30 x 30 to 40 * 40 to 50 * 50

Width (m) 1-6 1-6 1-1-1-1-6 June

Remark:

1, our company produces the geogrid regular grid size of 12.7 mm and 25.4 mm.

2, regular width is 2 m, 4 m and 6 m.

3, the strength of the geogrid, width, and the grid size can customize according to the requirement of the user

- Q: Which floor is paved on the roadbed

- Fixed grid end, by laying machine or manual will grill slowly pulled forward each shop, shop 10 meters long artificial investigation at a time, until a volume grating puwan, put the next volume, operation with; 3, ground shop: Volume long unit as the laying of the long, should be covered grille with long period, then the overall check again laying quality, then laying the next paragraph, a laying, grille grille to overlap a grid spacing for the lap length, tie fixed line continues to spread second section direction.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- At the same time has the ability to adapt to the deformation of good, and has good drainage capacity of plane surface, soft multi gap has good friction coefficient can increase soil particle adhesion ability, can prevent the fine particles by preventing particulate loss and eliminate excess water, the surface is soft protection ability good. According to the length of filament is divided into filament non-woven geotextile or short silk non-woven geotextile. They can play a very good filtering, isolation, reinforcement, protection and other functions, is a widely used geosynthetics. The tensile strength of the filament is higher than that of the short filament. Mainly is the high quality polyester staple fiber (fiber based 4-9dtex, length 50-76mm) can also according to the requirements of production of polypropylene, nylon, vinylon fiber or mixed needle nonwoven geotextile. It features 1 isolation of 2 filtered 3 drain 4 reinforcement

- Q: The tensile strength of a steel bar is about the number of cattle per square millimeter per square millimeter. The tensile strength of Gsa's cattle per meter, understand the carrying capacity of tensile Gsa every one meter in width is the number of cattle (considering Gsa gap), or single Gsa every one meter in length tensile capacity is the number of cattle (the size effect of Gsa does not consider the length direction). Please advise!

- The tensile strength of geogrid is most units per meter number kn, because the steel mesh size is uncertain, unlike the types of glass fiber grid less, as long as know what type of glass fiber yarn will be able to know what is the tension

- Q: Who knows the laying method of geogrid?

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: How do geogrids enhance the stability of steep road embankments?

- Geogrids enhance the stability of steep road embankments by providing reinforcement to the soil. They are installed within the embankment to distribute the tensile forces and prevent soil erosion or slippage. The geogrids act as a stabilizing layer, improving the overall strength and integrity of the embankment, making it more resistant to lateral movement and increasing its load-bearing capacity.

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are commonly utilized in shoreline stabilization projects to reinforce and stabilize the soil, preventing erosion caused by waves, currents, and other environmental factors. They are effective in providing long-term erosion control by distributing loads and preventing soil movement, making them a suitable solution for shoreline protection.

- Q: What are the advantages of using geogrids in ground improvement for liquefaction mitigation?

- There are several advantages of using geogrids in ground improvement for liquefaction mitigation. Firstly, geogrids provide increased stability to the soil by reinforcing it. They are placed in the ground to create a strong and stable layer, preventing soil liquefaction during earthquakes or other seismic events. This reinforcement helps to improve the overall strength and load-bearing capacity of the soil, making it less susceptible to liquefaction. Secondly, geogrids can improve the drainage properties of the soil. By creating a network of interconnected voids, they allow water to drain more efficiently, reducing the excess pore water pressure that contributes to liquefaction. This improved drainage helps to maintain the integrity and stability of the soil, even under seismic loading. Additionally, geogrids are cost-effective compared to other ground improvement techniques. They are relatively easy to install and require minimal excavation, reducing construction time and costs. Moreover, their long lifespan and durability make them a sustainable solution for liquefaction mitigation, minimizing the need for frequent maintenance or replacement. Overall, the use of geogrids in ground improvement for liquefaction mitigation offers enhanced stability, improved drainage, and cost-effectiveness, making them a valuable tool in mitigating the risks associated with soil liquefaction.

- Q: What are the environmental benefits of using geogrids?

- Geogrids offer several environmental benefits, including improved soil stability and erosion control. By reinforcing soil structures, geogrids help prevent soil erosion and the loss of valuable topsoil, which is crucial for maintaining healthy ecosystems. Additionally, geogrids can be used in slope stabilization, reducing the risk of landslides and protecting nearby habitats. The use of geogrids also promotes sustainable construction practices by minimizing the need for excessive excavation and the use of additional materials, thus reducing the overall environmental impact of infrastructure projects.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas?

- Geogrids improve the performance of geosynthetic-reinforced slopes in liquefaction-prone areas by providing additional strength and stability. These synthetic materials are used to reinforce the soil and prevent it from shifting or sliding during liquefaction events. The geogrids act as a reinforcement layer within the soil, increasing its shear strength and reducing the potential for slope failure. Additionally, geogrids help to distribute loads more evenly across the slope, reducing stress concentrations and improving overall slope stability in liquefaction-prone areas.

- Q: The difference between steel plastic two-way geogrid and steel plastic geogrid

- One way steel plastic geogrid is longitudinal tension requirements, only the detection of longitudinal tension.

Send your message to us

Shandong Embellish Warp-Knitted Geogrids for Roads

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords