SGCC prepainted steel coil,ppgi prepainted galvanized steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | steel | Thickness: | 0.12-2.0mm |

| Place of Origin: | Shandong China (Mainland) | Brand Name: | CNBM | Model Number: | DXTP1792 |

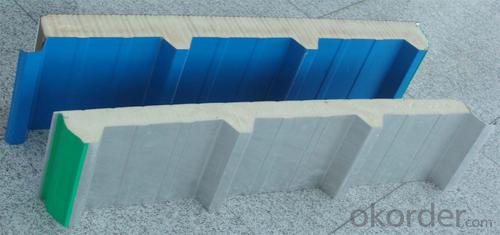

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated,Coated,Chromate, oil/unoil, bright finish, spangle, anti-finger print |

| Application: | Ship Plate | Special Use: | High-strength Steel Plate | Width: | 1250mm or under |

| Length: | as per customer's request | color: | all the RAL or the sample | Zinc coating: | 40-275g/m2 |

| Coil ID: | 508mm/610mm | Features: | Corrosion resistance, heat resistance, aesthetics, versatility | Coil weight: | 3-8 Metric Ton |

| MOQ: | 25 Metric Tons | main product: | prepainted galvanized steel coil | prepainted galvanized steel coil: | prepainted steel coil |

| Competitive Advantages: | Best quality and reasonable price |

Packaging & Delivery

| Packaging Detail: | prepainted galvanized steel coil with standard seaworthy package. |

| Delivery Detail: | within 25day after receiving the 30% deposit |

Product Description

| Product Description Main characteristics : 1.strong corrosion resistance 2.surface quality 3.conducive to deep processing 4.economy and practicality Applications: 1) Pre-galvanized steel tubes and pipes 2) Galvanized steel channels and profiles 3) Armoring cable |

|

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | Q195-Q235, SPCC, SPCD, SPCE, SGCC (DX51D+Z), SGCD (DX52D+Z), etc |

Thickness | 0.12-2.0mm |

Width | 500-1250mm(usual size: 762mm,914mm,1000mm,1200mm,1219mm,1220mm,1250mm,) |

Base metal | prepainted galvanized steel coil |

Zinc coating | 40-275gsmm |

Coil ID | 508mm/610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 5-10days after signing contract |

Price | FOB&CNF&CIF price |

Payment terms | TT or LC |

Monthly supply | 5,000MT per month |

MOQ | 25MT |

- Q: What are the safety precautions while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): It is essential to wear suitable PPE, including steel-toed boots, safety glasses, gloves, and a hard hat. This protective gear will safeguard against potential hazards like falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers handling steel coils have received thorough training in safe lifting techniques. This involves lifting with the legs, maintaining a straight back, and avoiding twisting motions. By utilizing proper lifting techniques, the risk of back strains and injuries can be minimized. 3. Secure Storage and Stacking: When storing or stacking steel coils, ensure they are placed on a stable and level surface. Employ appropriate storage equipment like racks or pallets to prevent coils from shifting or falling. Stack the coils securely to prevent toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Conduct regular maintenance on equipment like forklifts or cranes used for moving the coils to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols among workers involved in handling steel coils. This can involve hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with limited visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, thereby increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, employ appropriate lashing and securing methods to prevent movement or falling during transportation. This may entail using straps, chains, or other restraints to keep the coils securely in place. 8. Emergency Preparedness: Establish an emergency plan in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are easily accessible. By adhering to these safety precautions, the likelihood of accidents and injuries when handling steel coils can be significantly reduced, creating a safer work environment for all individuals involved.

- Q: What are the cost implications of using steel coils in manufacturing?

- The cost implications of incorporating steel coils into the manufacturing process can vary based on multiple factors. To begin with, the overall manufacturing expenses can be significantly affected by the cost of purchasing the steel coils themselves. Steel prices are influenced by various factors, including supply and demand, global market conditions, and any tariffs or trade regulations in place. Fluctuations in steel prices directly impact the cost of acquiring steel coils, which, in turn, affects the overall manufacturing cost. Furthermore, transportation costs can be influenced by the size and weight of the steel coils. Due to their heaviness and bulkiness, steel coils often incur higher shipping expenses as they require increased transportation resources. Additionally, shipping costs can be influenced by the distance between the steel supplier and the manufacturing facility. Moreover, the manufacturing costs can be influenced by the processing and transformation of steel coils into finished products. Depending on the desired end product, additional steps such as cutting, shaping, welding, or coating may be necessary. These supplementary processes require specialized machinery, skilled labor, and extra materials, all of which contribute to the overall manufacturing expenses. Considering the quality and durability of the steel coils is also essential. Although using high-quality steel coils may initially result in higher costs, it can lead to long-term savings by reducing the need for repairs or replacements. Furthermore, it is crucial to consider any regulatory or compliance requirements associated with the use of steel coils in manufacturing. Certain industries may have specific standards or certifications that need to be met, resulting in additional costs for testing, inspections, or compliance procedures. Lastly, it is important to acknowledge the potential cost savings that can be achieved through the utilization of steel coils in terms of efficiency and productivity. Steel coils are often preferred in manufacturing due to their strength, durability, and ease of fabrication. These characteristics can lead to improved production processes, reduced waste, and higher overall output, which can offset the initial cost of using steel coils. In conclusion, the cost implications of using steel coils in manufacturing are influenced by several factors, including steel prices, transportation costs, additional processing requirements, quality considerations, regulatory compliance, and potential productivity gains. A careful analysis and consideration of these factors are crucial for understanding the overall cost impact on manufacturing operations.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Yes, steel coils can be used in the manufacturing of machinery and equipment. Steel coils are versatile components that provide strength, durability, and stability to various industrial applications. They can be shaped, cut, and formed into different parts and components necessary for the machinery and equipment manufacturing process. Steel coils are commonly used in the production of gears, shafts, frames, brackets, and other structural elements. Additionally, they can be processed further to create specialized components such as springs or fasteners. The use of steel coils in machinery and equipment manufacturing ensures that the end products are of high quality, capable of withstanding heavy loads, and have a long lifespan.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: How are steel coils used in the production of railway tracks?

- Steel coils are a crucial component in the production of railway tracks. These coils are typically made of high-quality steel and are used to manufacture the rails that form the foundation of the tracks. The process begins with the steel coils being unwound and fed through a series of machines that shape and form them into the desired rail profile. The steel coils are first passed through a rolling mill, where they are gradually flattened and shaped into long strips of steel. This process is known as hot rolling, as the steel is heated to high temperatures to make it more malleable. The rolling mill applies immense pressure to the steel, gradually transforming it into the desired rail shape. Once the steel coils have been rolled into the required shape, they are then cut into individual rail lengths. These lengths can vary depending on the specifications of the railway track being produced. The rail lengths are then further processed to remove any imperfections and straighten them out. After this initial shaping and processing, the rails are subjected to a series of additional treatments. These treatments may include heat treatment to enhance their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready to be installed on the railway track. They are laid out in a carefully planned pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, allowing trains to travel smoothly and safely. In summary, steel coils play a vital role in the production of railway tracks. They are used to manufacture the rails that form the foundation of the tracks, ensuring durability, strength, and a smooth surface for trains to run on. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: What are the uses of galvanized steel coils?

- Galvanized steel coils have a wide range of uses in various industries due to their unique properties. Here are some common uses of galvanized steel coils: 1. Construction: Galvanized steel coils are widely used in the construction industry for various applications. They are used to manufacture roofing sheets, wall panels, and structural components. The galvanized coating helps to protect the steel from corrosion, extending its lifespan and ensuring durability in harsh weather conditions. 2. Automotive industry: Galvanized steel coils are used in the automotive industry for manufacturing different parts and components. These coils are used to manufacture body panels, chassis, and other structural parts of vehicles. The galvanized coating provides excellent corrosion resistance, which is crucial for the longevity of automobiles. 3. Appliances: Galvanized steel coils are used in the production of various household appliances, such as refrigerators, washing machines, and air conditioners. The coils are used to manufacture the outer panels and cabinets of these appliances, providing them with a strong and durable structure. 4. Agriculture: Galvanized steel coils find applications in the agriculture sector as well. They are used to manufacture agricultural equipment, such as grain storage silos, irrigation systems, and livestock enclosures. The galvanized coating protects the steel from rust and corrosion, ensuring the safety and longevity of these agricultural structures. 5. Industrial applications: Galvanized steel coils are widely used in various industrial applications. They are used for manufacturing ductwork, ventilation systems, and industrial piping. The galvanized coating helps to resist chemicals, moisture, and other environmental factors, making it an ideal choice for industrial environments. 6. Electrical industry: Galvanized steel coils are used in the electrical industry for manufacturing electrical enclosures, conduit pipes, and cable trays. The galvanized coating provides excellent protection against corrosion and ensures the safety and durability of electrical installations. 7. Furniture manufacturing: Galvanized steel coils are used in the furniture manufacturing industry for producing furniture frames, shelves, and cabinets. The galvanized coating adds strength and durability to these furniture pieces, making them long-lasting and resistant to corrosion. Overall, galvanized steel coils have a wide range of uses in various industries due to their excellent corrosion resistance, durability, and strength. They are a cost-effective and reliable choice for applications that require protection against rust and environmental factors.

- Q: What are the different grades of steel used in coils?

- There are several different grades of steel that are commonly used in coils, including low carbon steel, high carbon steel, stainless steel, and advanced high-strength steels. Each grade has its own unique properties and is chosen based on the specific requirements of the application, such as strength, corrosion resistance, and formability.

- Q: the comparison needed between other steel

- *Mild steel is ductile and can be easily machined. Generation of heat is less than that of steel machining.So, the tool can have better life and you can do more machining. Cost factor is of prime importance as other steel are more costly than Mild steel. Mild steel, a grade of steel that does not harden when heated and chilled with cold water, so further machining can be easy. Mild steel is easily available.You will find it in your scrape yard. No need to change the tool repeatedly and no special tools are required for machining. Above is the comparisation between alloy steel,SS and superalloys. Cutting speed and feed does not required special skills.

- Q: How are steel coils used in the production of electrical transformers?

- Steel coils are used in the production of electrical transformers as they provide the core structure for the transformer. The steel coils are wound with insulated copper wire to create the primary and secondary windings of the transformer, which allow for the transformation of electrical energy from one voltage level to another. The steel coil helps to conduct and distribute magnetic flux within the transformer, ensuring efficient energy transfer and reducing losses.

- Q: What are the challenges in coil edge trimming for narrow strips?

- There are several challenges in coil edge trimming for narrow strips. Firstly, one of the main challenges is maintaining accuracy and precision during the trimming process. Narrow strips require a high level of precision to ensure that the edges are trimmed evenly and smoothly. Any deviation from this precision can result in uneven edges or burrs, which can affect the overall quality of the strip. Secondly, there is the challenge of controlling the strip tension. Narrow strips are more prone to tension issues, as they have less surface area to distribute the tension evenly. This can lead to problems such as strip breakage or stretching, which can impact the final product's quality. Another challenge is avoiding material waste. Narrow strips often have a smaller margin for error, meaning that any mistakes in the trimming process can result in a significant amount of wasted material. Minimizing material waste is crucial for cost-effectiveness and sustainable manufacturing practices. Additionally, maintaining a high production rate can be challenging when working with narrow strips. The trimming equipment needs to be able to handle the high speed required for efficient production while still maintaining accuracy and precision. This requires the use of advanced machinery and technology to ensure smooth and efficient operations. Lastly, the handling and transportation of narrow strips can also pose challenges. Due to their small size, narrow strips are more susceptible to damage during handling and transportation. Proper care and handling techniques need to be implemented to prevent any potential damage, which could affect the quality of the final product. Overall, the challenges in coil edge trimming for narrow strips revolve around precision, tension control, material waste, production rate, and handling. Overcoming these challenges requires the use of advanced technology, skilled operators, and careful attention to detail throughout the entire process.

Send your message to us

SGCC prepainted steel coil,ppgi prepainted galvanized steel coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords