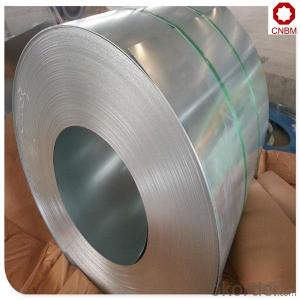

SGCC Hot Dipped Zinc Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:SGCC Hot Dipped Dx51d Dx52d Zinc Galvanized Steel

Surface Treatment:Galvanized

Certification:ISO, SGS, BV, RoHS, IBR

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Roofing,Wall,Structure...

Edge:Mill

Stock:Stock

Steel Grade:Dx51d,SPCC,SGCC,CGCC,S350gd

Name:SGCC Hot Dipped Dx51d Dx52D Zinc Galvanized Steel

Thickness:0.14-1.2mm

Width:600-1250mm

Zn Coating:40-275GSM

Surface:Oiled,Galvanized,Chromated

Spangle:Zero,Small,Big,Regular

Coil Weight:3-10tons

Coil ID:508/610mm

Certificate:BV,ISO

Test:QA-QC-Mtc

Export Markets:Global

Additional Info.

Packing:1.Brown Paper 2.Plastic Cloth 3.Galvanized Plate

Standard:Thickness: 0.12mm-3mm

Origin:Shandong, China

HS Code:721049000

Production Capacity:30000 Tons/Year

Product Description

SGCC Zinc Coated Galvanized Steel Coil

ISO system

SGS and BV audited company.

Industry experience over 10 years.

Management systems-internal software

Finished product inventory-more than 500 tons.

Raw material inventory -over 800 mertic tons.

Shipment of goods -more than 30 countries worldwide.

We have the most convenient transport and prompt delivery.

We offer competitive price with best service.

We have high technical production line with top quality products.

We have win high reputation based on best quality products.

Specifications:

1. Zinc: 30g-275g/sqm

2. Coil weight:4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 30000MT/month

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 20 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Product Specification:

| Commodity | Galvanized Steel Coil For Construction | |||||||

| Technical Standard: | JIS 3302 / ASTM A653 / EN10143 | |||||||

| Grade | Base plate Style | Material | Standard | Application | ||||

| GI PLATE | TDC51D+Z | DC51D+Z | Commercial | |||||

| TDC52D+Z | DC52D+Z | Drawing/stamping | ||||||

| TDC53D+Z | DC53D+Z | Deep Drawing/stamping | ||||||

| TS280GD+Z/TS350GD+Z | S280GD+Z/S350GD+Z | Structure | ||||||

| TS550GD+Z | S550GD+Z | High strength structure | ||||||

| GL PLATE | TDC51D+AZ | DC51D+AZ | Commercial | |||||

| TDC52D+AZ | DC52D+AZ | Drawing/stamping | ||||||

| TS250GD/300GD/350GD+AZ | S250GD/300GD/350GD+AZ | Structure | ||||||

| TS550GD+AZ | S550GD+AZ | High strength structure | ||||||

| Coating Character | Pencil hardness | ≥H/2H | Category of Painting | Polyester | PE | |||

| Reverse impact | ≥9J/6J | High-durability polyester | HDP | |||||

| T bending | ≤ 3T/ 5T | Silicon modified polyesters | SMP | |||||

| Cuppingtest | ≥ 6mm/ 4mm | Polyvinylidene fluoride | PVDF | |||||

| MEK cleaning | ≥100/50 time | Easy-Cleaning | EC | |||||

| Primerabout 5 to 7 microns ; Top coated: about 8-20microns ; Back coated: about 5-15 microns (usual:5-7micron) | ||||||||

| Inspection | MTC will be handed on with shipping documents , accept the third party inspection | |||||||

| We accept the third party certificatation test | ||||||||

Hot Dip Cold Rolled Galvanized Steel coil

| Standard | AISI , ASTM , DIN , GB , JIS |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

| Width | 600-1500mm |

| Thickness | 0.12-3mm |

| Zinc Coating | 40-275g |

| Coil ID | 508/610 mm |

| Coil Weight | 3-8 tons |

| Type of Coating | Hot dipped galvanized or Electronic Galvanized |

| Surface Structure | zero spangle / minimized spangle / regular spangle/ big spangle |

| Surface Treatment | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Package | export standard, plastic film+water proof paper + steel plate+ packing steel strip |

| Application | PPGI coil;construction,hardware, home appliances,interior decoration etc. |

| Price Items | FOB , CFR , CIF |

| Payment Items | Negociate |

| Delivery Time | Delivery as your request |

| Remark | Insurance is all risks |

| We accept the third party certification test |

Technical Data >>>

Chemical Composition:

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 |

Hot Dip Cold Rolled Galvanized Steel Coil Mechanical Properties

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should always wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect themselves from potential hazards. Additionally, it is crucial to ensure that the work area is clean and free from any debris or obstacles that may cause accidents or tripping. Proper manual lifting techniques should be employed to avoid strain or injury when handling heavy steel coils. Workers should also be trained in the proper use of equipment such as cranes or forklifts to safely transport and store the coils. Regular inspections of equipment and proper maintenance should be conducted to prevent any malfunctions or accidents. Lastly, employees should be aware of emergency procedures and have access to fire extinguishers and first aid kits in case of any unexpected incidents. Overall, prioritizing safety measures and being vigilant can greatly minimize the risks associated with working with steel coils.

- Q: What are the different coil coating options available for steel coils?

- Steel coils have several coil coating options available, each with its own unique benefits and applications. 1. The affordability and versatility of polyester coil coatings make them the most commonly used option. These coatings offer good durability, weather resistance, and color retention, making them suitable for a wide range of indoor and outdoor uses. 2. PVDF coil coatings provide excellent resistance to fading, chalking, and chemical exposure. They are highly durable, making them ideal for exterior applications that require long-term performance. PVDF coatings also have good dirt and stain resistance. 3. Polyurethane coil coatings offer exceptional adhesion and flexibility. They are often used in applications that require excellent resistance to abrasion, impact, and corrosion. Polyurethane coatings also provide good color retention and weather resistance. 4. SMP coatings combine the benefits of polyester and silicone coatings. They offer enhanced resistance to chalking, fading, and industrial pollutants. SMP coatings are commonly used in agricultural, industrial, and architectural applications. 5. PVC coil coatings provide excellent chemical resistance and are frequently used in applications where resistance to acids, alkalis, and solvents is crucial. These coatings also offer good color retention and have a low environmental impact. 6. Epoxy coatings provide exceptional adhesion and corrosion resistance. They are often used in demanding environments such as the marine or chemical processing industries. Epoxy coatings can be customized to meet specific performance requirements. 7. Acrylic coatings offer excellent color retention, UV resistance, and gloss retention. They are commonly used in architectural applications where aesthetics are important. Acrylic coatings also provide good resistance to weathering and chemicals. When choosing a coil coating option, it is important to consider the specific requirements of the application. Factors such as durability, weather resistance, chemical resistance, adhesion, and color retention should be taken into account to ensure the best performance and longevity of the steel coils.

- Q: Where can I find a discount online for Stainless Steel Magnetic Knife Rack

- listed under are a number of them: 5.0 out of 5 stars could no longer be extra effective, March 3, 2006 by applying Denise M. Henderson (Groveland, CA united states of america) stable sturdy shape. seems great. common installation. appropriate length. Magnet appropriate capability. only confirm you place the back of the blade to the magnet first, then turn the knife flat onto the magnet. or you will cut back to rubble the knife blade. 5.0 out of 5 stars purchase it!, November a million, 2004 by applying T. Berktan (Le chef amateur) (Chicago, IL) i admire this knife holder. at first it rather is sanitary. would not take counter area and IT seems SO COOL on the wall. i might purchase it lower back with out hasitation if I had to. 5.0 out of 5 stars Very clever and seems great!! i like it!!, August 24, 2005 by applying Stacy S. Wooten i in my opinion, rather like this knife holder. It replaced into common to place up and seems great on my kitchen backsplash. it rather is long sufficient to hold all my knifes (approximately 8). it rather is a competent, stable magnet, and seems very stylish in my kitchen. i might surprisingly propose this product to everyone searching for a magnetic knife holder.

- Q: How do steel coils contribute to the renewable energy sector?

- Steel coils contribute to the renewable energy sector by playing a crucial role in the manufacturing of wind turbines and solar panels. These coils are used to produce the structural components of wind turbine towers and solar panel support structures. Additionally, steel coils are also utilized in the construction of transmission lines and grid infrastructure for renewable energy projects, ensuring efficient distribution of electricity generated from renewable sources.

- Q: Building the bulwurk, general use on trawlers. What kind of steel is best suited.

- How big is your trawler going to be and what use, The ones you see off the Alaska Coast or a Gulf Coast Shrimper? My preference in today's economy would not make sense and that is Aluminum.....not steel at all, maybe even Fiberglass, but $$$$ talk so Steel is cheaper, but you need to know what you are doing. The designer of the hull should have specified the right /preferred grade. It today's world there are many more choices available. You use a mild steel, most often grade A or B, but some applications call for grade D. Check your blue prints and list of materials. Edit. Ok I understand. There are 2 ways to go. One is use a relatively cheep steel and use higher cost epoxy primers and paint, often requiring special surface preparation just before priming, or two, using a much higher cost steel with more chrome and nickel in it. Grades that begin with #3xxx These are weldable with rods that are available, and can be welded directly to mild steels. However these are 3X the cost. If your a Shrimper, I'm guessing gulf coast. I worked with several boat yards in the 70's installing spray urethane foam for insulating there holes. So I've been around lots of small yards from Florida to Texas. I'd call the nearest steel warehouse and ask what they would recommend. You might find what you want at a scrap yard. I've lucked out several times picking up 1/4 plate scrap$ and I'd bet the scrapyard guy would know just what you need. I know there are places to get what you need in Mobile and New Orleans. Good luck!

- Q: What's the length of a coil of cold rolled steel? Is there a standard?

- But in the process of production, not the large volume, a few kilometers long have. The small volume sold by the finished product is much shorter.

- Q: I beat fallout 3 and i downloaded broken steel expansion. I have no idea how to get to broken steel in other words i do not know how to start playing it.

- after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: Okay basically bought my girlfriend Tiffany sterling silver necklace for her birthday and now christmas is coming up i want to buy her this DG Necklace. BUT i have discovered its steel. And its ?110. I am not a rich man i am infact quite young and we have been together for an incredibly long time! I wanted to know is Steel seen as a cheap necklace, whats your say? Don't give me all this bull about her being grateful as she does not expect this. BUT I WANT IT TO BE NICE. Whats your say? Is Steel good? Does it get dirty? Does it shine? Is it worth it? Thanks x

- I think steel would probably be better than silver. (Since silver tarnishes.) I have a piece of steel jewellery and it looks the same as silver. You should definately get her it.

- Q: Can steel coils be used in outdoor applications?

- Yes, steel coils can be used in outdoor applications. Steel is known for its durability and strength, making it suitable for a wide range of outdoor uses. Steel coils are often used in applications such as construction, automotive manufacturing, and transportation industries. They are resistant to harsh weather conditions, including rain, snow, and UV exposure. Additionally, steel coils are often coated with protective finishes, such as galvanized or painted coatings, to further enhance their resistance to corrosion and extend their lifespan. Overall, steel coils are a reliable and versatile option for outdoor applications due to their strength, durability, and resistance to environmental factors.

Send your message to us

SGCC Hot Dipped Zinc Galvanized Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords