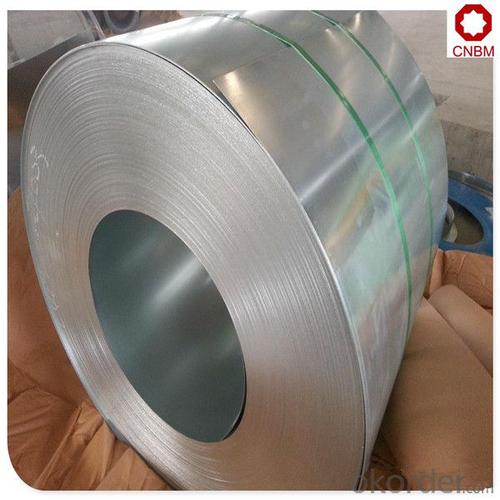

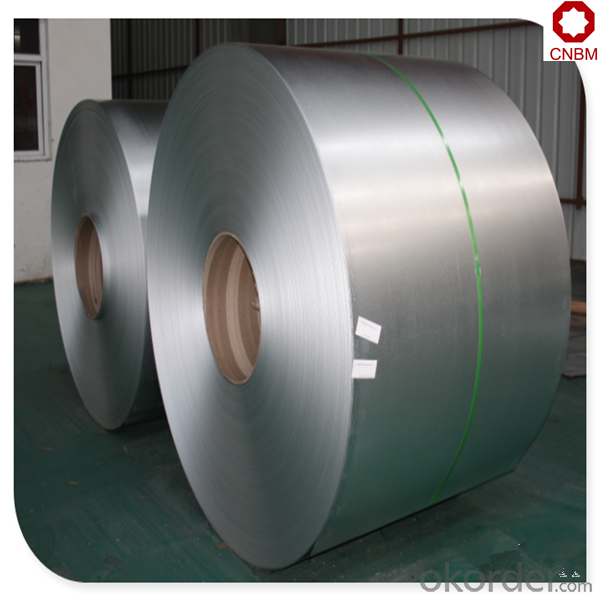

Galvanized steel coil sgcc hot dipped good quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35670 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

FAQ:

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Can steel coils be coated with silicon?

- Yes, steel coils can be coated with silicon through a process known as siliconizing or silicon coating. This enhances the steel's resistance to corrosion, improves its electrical conductivity, and provides other beneficial properties.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: How are steel coils used in the manufacturing of automotive body panels?

- Steel coils are used in the manufacturing of automotive body panels by being formed and shaped into the desired panel shape through processes such as stamping, pressing, and roll forming. These coils provide the necessary strength and durability required for automotive body panels, ensuring the structural integrity and safety of the vehicle.

- Q: What are the different methods of tempering steel coils?

- There are several methods of tempering steel coils, including air tempering, oil tempering, salt bath tempering, and induction tempering. Each method involves heating the steel coils to a specific temperature and then allowing them to cool slowly to achieve the desired level of hardness and toughness. Air tempering involves exposing the steel coils to ambient air for gradual cooling, while oil tempering involves immersing them in heated oil. Salt bath tempering involves placing the coils in a bath of molten salt, and induction tempering uses electromagnetic induction to heat the coils. The choice of tempering method depends on the specific requirements of the steel and the desired properties of the final product.

- Q: What are the different types of steel coil slitting techniques?

- There are several types of steel coil slitting techniques, including rotary slitting, loop slitting, and oscillating slitting. Rotary slitting involves using circular blades to cut the steel coil into narrower strips. Loop slitting involves creating a loop in the steel coil and then cutting it with straight blades. Oscillating slitting uses a reciprocating blade that moves back and forth to cut the coil into smaller widths.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- For outdoor applications, there are several commonly used surface treatments for steel coils that enhance durability, corrosion resistance, and appearance. Examples of these treatments include: 1. Galvanized: This treatment involves applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc applied to the steel surface, offering superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with various coatings to enhance appearance and protect against corrosion. The paint can be applied in single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: This type of paint coating is applied as a powder and then cured under heat, resulting in a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are commonly used in architectural applications where aesthetics and durability are important. These various surface treatments for steel coils offer different levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: How do steel coils differ in terms of size and weight?

- Steel coils can vary greatly in terms of size and weight depending on their intended use and production process. The size of a steel coil is typically measured in terms of its outer diameter, inner diameter, and width. The outer diameter refers to the total diameter of the coil, while the inner diameter refers to the diameter of the hollow center of the coil. The width of the coil refers to the distance between the two flat sides of the coil. In terms of weight, steel coils can range from a few hundred pounds to several tons. The weight of a coil is primarily determined by its size and the type of steel used. Coils made from high-strength steel tend to be heavier due to their higher density, while coils made from lower-grade steel can be lighter. The size and weight of steel coils are crucial factors in determining their transportability and handling. Smaller and lighter coils are generally easier to handle and transport, making them more suitable for applications where maneuverability is important. On the other hand, larger and heavier coils are often used in industries where strength and durability are essential, such as construction and automotive manufacturing. Overall, steel coils can vary significantly in terms of size and weight, allowing for a wide range of applications and customization to meet specific requirements in various industries.

- Q: How do steel coils contribute to the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they provide structural support and enhance the durability of various components. They are commonly used in transformers, motors, and generators, where they serve as the core material due to their magnetic properties. The steel coils help to create and maintain magnetic fields, ensuring efficient energy transfer and enhancing the overall performance of electrical equipment.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components by being formed and shaped into various parts such as frames, body panels, and suspension components. These coils are typically cut, stamped, and welded to create the desired shapes and sizes needed for the automotive industry.

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

Send your message to us

Galvanized steel coil sgcc hot dipped good quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35670 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords