Semi-auto MDF Melamine Laminating Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Semi-auto MDF melamine laminating hot press machine

Products detail

Semi-auto MDF melamine laminating hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Semi-auto MDF melamine laminating hot press machine is availale according to your requirements!

Features

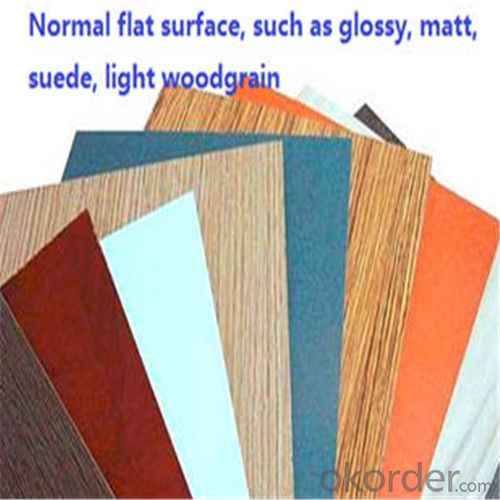

Semi-auto MDF melamine laminating hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Semi-auto MDF melamine laminating hot press machine are for)

Semi-auto MDF melamine laminating hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Semi-auto MDF melamine laminating hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What is the production process of the hydraulic press?

- The production process of hydraulic press is complicated. In order to realize the automation of machinery, it is necessary to complete a series of conversion circuit operation in the electromechanical drive system. These operations need to be done in a certain order and within the required time. To meet these complex requirements, relying solely on single linkage control is clearly impossible. The motor must also be controlled by various factors in the process of starting, shifting, reversing and braking, as well as the working state of the production equipment.

- Q: How can the air compressor be more convenient to drain water?

- This is a passive drainage method. A better, more direct way of draining is to install an electronic drain valve directly on the discharge pipe. Because the electronic blowdown valve has the function of regular discharge (fixed discharge time and fixed emission interval), the time can be adjusted flexibly according to the working conditions of the air compressor, and it is more effective and reliable in practical application.

- Q: What is the exhaust volume of SA energy saving 75kW screw air compressor?

- SA shock energy-saving screw compressor has many kinds, mainly divided into permanent magnet screw air compressor series, two-stage compression screw air compressor series, two-stage compression, screw air compressor series permanent magnetic frequency two-stage compression screw air compressor series. There are many models, too. Here's a brief one:SA 75kW permanent magnet frequency conversion energy-saving screw air compressor, pressure from 7.5 kg -12.5 kg, exhaust volume in 2.6-13.8 cubic meters per minute.SA shock 75KW two-stage compression screw air compressor, pressure from 5.5 kg to 12.5 kg, the exhaust volume in 11.7-19.6 cubic meters per minute.SA shock 75kW efficient frequency conversion two-stage compression screw air compressor, pressure from 4.5 kg -12.5 kg, exhaust volume in 3.8-19.5 cubic meters per minute.SA 75kW permanent magnet frequency conversion two-stage compression screw air compressor, the pressure from 4.5 kg to 12.5 kg, the exhaust volume in 2.9-20.7 cubic meters per minute.

- Q: What accessories does the air compressor contain?

- The air compressor is the base of product of modern industry, electrical and automation is often said that there is full pneumatic meaning; and the air compressor is to provide power source, pneumatic system is the core equipment of electromechanical drainage main source device, it is the prime mover (usually motor) into mechanical energy conversion device of gas pressure can, is the pressure of compressed air generator.

- Q: What is an air compressor for?

- The air compressor belongs to general machinery. Can provide stable, reliable, uninterrupted compressed air source.

- Q: What is the volume flow of the air compressor?

- That is, how many cubic meters of exhaust per minute, the amount of exhaust is about 6 times the value of power. For example, 7 cubic meters of exhaust, using 45KW machines

- Q: What happens when the air compressor is plugged in and does not work?

- Air compressors cause about four of these problems;1 、 the power line contact is bad, check the input power supply and the output power line;2, check the power line junction box housing, there is a touch switch, the switch can be pulled and pressed, if it is now in a state of press, please pull it up;

- Q: What are the characteristics of a screw compressor?

- Working principle of compressor main engineThe core components of screw type air compressor is a compressor, is a new type compressor in the air is compressed by the alveolar volume change is installed in the casing parallel rotor meshing and achieve. The rotor side in the case and it withprecision internal rotation so that the gas rotor slot between continuously produce periodic volume changes along the rotor axis from the suction side to the discharge side suctioncompression exhaust complete three working process. Therefore, the technology of twin screw rotor determines the grade of the screw compressor. (related to the type of line see the page "double screw compressor core technology" column).

- Q: What is the reason that the air compressor doesn't load?

- 1. check the loading solenoid valve2 check the pressure switch or pressure sensor3 check whether the diaphragm of the intake valve is damaged or not, and make sure the motor is broken4 is the intake valve open?

- Q: What is the working principle of air compressor?

- Piston compressor is one of the earliest compressor designs, but it is still the most versatile and very efficient compressor. The piston compressor moves the piston forward in the cylinder through the connecting rod and the crankshaft. If only one side of the piston is compressed, it is called a single action. If the piston is on both sides of the upper and lower sides, it is called double action.

Send your message to us

Semi-auto MDF Melamine Laminating Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches