Automatic Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automatic plywood plate hot press machine

Products detail

Automatic plywood plate hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Automatic plywood plate hot press machine is availale according to your requirements!

Features

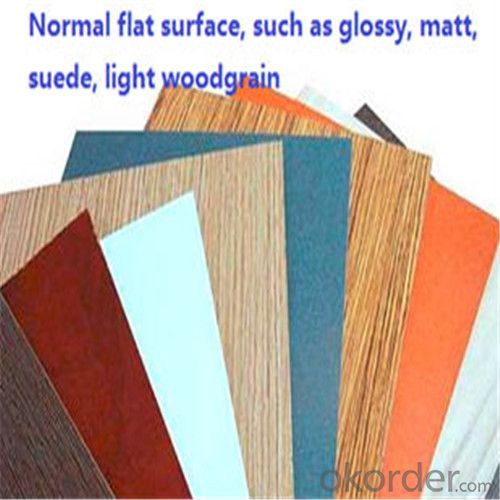

Automatic plywood plate hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Automatic plywood plate hot press machine are for)

Automatic plywood plate hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Automatic plywood plate hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: Screw air compressor in the end do not use gas tank?

- That's what you have to use, because he doesn't want the piston machine itself to have a jar, unless your screw machine itself contains a jar and most of it comes with it. Also, unless your pipe is very thick, equivalent to a gas tank, then it is impossible to match

- Q: What are the factors that affect the air compressor exhaust?

- 1, the air compressor exhaust volume usually refers to the unit time, air compressor, the last stage of the exhaust gas converted to the first intake of the pressure and temperature of the gas volume value.2, the influence of inlet pressure Ps on the existing air compressor, its exhaust volume decreases with the intake pressure and decreases with the increase of intake pressure. The current environment of North China Pharmaceutical Huasheng Company Limited by air suction filter into a suction chamber, the suction, compression, cooling into the two stage. Taking into account the exhaust pressure of centrifugal compressor is 0.2MPa, and through F8 filter, if the 0.2MPa of the compressed air as a suction pressure, connected with the ZW -6/7 type piston type air compressor suction, which improves the suction pressure of air compressor, thereby increasing the exhaust volume of air compressor.3, the influence of inlet temperature T1 on the intake temperature is mainly achieved by the effect of intermediate cooling. Although the improvement of cooling effect can increase the intake, it can not meet the requirement of increasing the exhaust capacity greatly. The influence of the speed of N increase speed can improve the capacity, can achieve the goal, but the shaft power of screw type air compressor will increase a lot, the need to replace the motor; at the same time, air compressor operation condition deteriorates, valve, piston ring, packing will shorten the life, security is not guaranteed.4, the influence of clearance volume, the cylinder diameter decreases, the clearance volume can improve the exhaust capacity, but it can not meet the requirements of greatly improving the exhaust capacity.5, the impact of leakage, for perennial disrepair and parts damaged machines, leakage increases, the impact of its exhaust volume is very serious, but obviously the current situation does not belong to this.

- Q: How long is the service life of an air compressor? Are there any uniform standards?

- Due to the design level, manufacturing quality, service environment, gas consumption and size, maintenance technology and management level is different, the air compressor of the same type, the service life will have great difference, and there is not a unified standard.The air compressor also has a problem of economic life and technical life. Technically, piston type air compressor is recommended for a period of ten years, but if the gas is large, or even twenty-four hours of operation, plus maintenance did not keep up, then perhaps within a few years of frequent failure, maintenance costs will be very high. For example, variable frequency twin-screw compressor, technically speaking, can not be bad for twenty years, but from an economic point of view, which manufacturers dare to promise you twenty years warranty.

- Q: How can the air compressor be repaired and maintained?

- Condensate discharge:The moisture in the air may condense in the tank, especially in wet weather, when the exhaust temperature is lower than the air pressure, dew point or stop cooling, more condensed water will be precipitated. The oil contains too much water will cause the oil emulsion, affect the safe operation of the machine, such as: bad compressor lubrication; oil and gas separation effect becomes worse, oil and gas separator pressure difference caused by corrosion of parts. Therefore, the condensate discharge schedule shall be established according to the humidity conditions.Condensate discharge method: should be in the machine shutdown, oil and gas separation tank without pressure, sufficient cooling, condensate after sufficient precipitation, such as before the start of the morning.Screw out the front plug of the ball valve at the bottom of the tank.Slowly open the ball valve drain until the oil flow out, close the ball valve.Screw the ball valve before the screw plug.

- Q: What are the specifications and models of air compressors?

- The specifications of the air compressor model is generally based on the power of the motor, such as screw air compressor 7.5KW is Desi Lan DSR-10A here is DSR, the motor -10A is referred to as LAN, 7.5KW, HP is 10HP, we call 10A or 10P, DSR-20A is 15KW, 20HP, so many types of factory is the factory or the abbreviation LOGO for most of the volume + power or exhaust,

- Q: What heating equipment does the hot press use?

- At present, the widespread use of heat conduction oil heater for hot die or hot pressing plate for indirect heating, hot runner mold / plate, circulating oil, has the advantages of cyclic heating, uniform heating, high precision of temperature control, and the electric heating rod is not easy to damage; disadvantages: direct electric heating, heat loss is slightly larger

- Q: Is the main reason for the energy-saving air compressor the main engine?

- The energy saving of air compressor mainly depends on the efficiency of the main engine (rotor linetype) and the efficiency of the motor.

- Q: What does air compressor load and unload mean?

- In general, the loading and unloading control changes the pressure of the compressed gas from Pmin to Pmax. Pmin is the minimum pressure to ensure that users work properly, also known as minimum pressure. The conversion relationship between Pmax, Pmin such as the formula: Pmax = (1 + 8) Pmin, which is a parameter in the 10% ~ 25% percentage. When we use the variable frequency speed regulation technology to realize the continuous adjustment of air supply, then the pipe network pressure will be maintained near the minimum pressure value Pmin.

- Q: What's the connection between an air compressor and a three-phase induction motor? Are they the same?

- The three-phase asynchronous motor of compressed air in the air compressor room is an important part of the air compressor, providing the driving power. Screw compressor as an example, the motor drag coupling, connected to the compressor chamber rotor, motor driven rotor rotation, compressed air.

- Q: Is the Rui Rui screw air compressor imported brand?

- Not imported. It belongs to a series under the Shanghai Wright air compressor

Send your message to us

Automatic Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches