Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Automatic melamine plywood plate hot press machine

Products detail

Automatic melamine plywood plate hot press machine is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Automatic melamine plywood plate hot press machine is availale according to your requirements!

Features

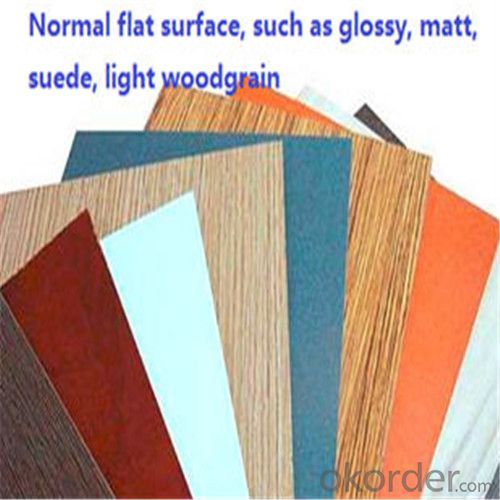

Automatic melamine plywood plate hot press machine is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Automatic melamine plywood plate hot press machine are for)

Automatic melamine plywood plate hot press machine for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Automatic melamine plywood plate hot press machine will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What kind of air compressor does the tire compressor need?

- From the performance point of view of nitrogen separation material nitrogen machine especially sensitive to oil pollution, tire air compressor nitrogen machine, is certainly the oilless air compressor, air compressor can therefore choose no choice in all kinds of air compressor oil series. Among them, no oil piston compressor prices in the oil free air compressor is the lowest price varieties, but the drawback is that noise, easy, bad, power consumption. Oil-free scroll compressor is the most suitable and nitrogen tire supporting air compressor, low noise, low energy consumption, the longest life, but the price is expensive, oil-free scroll air compressor imports is 10 times that of oil free piston. However, China has no oil scroll compressor has been made in recent years, Jiangxi has one of the world's largest oil-free scroll air compressor production base is under construction.

- Q: Air compressor use in smoke, how to do?

- Reason: air compressor inlet valve is not closed or air compressor is not uninstalled,Processing: 1. check the air compressor intake valve, and then wash it, such as the severe replacement of intake valve.

- Q: What is the automatic drain valve of the air compressor?

- After drainage, compressed air is compressed and saturated air. When the temperature is lowered, water is condensed from compressed air. The automatic drain valve is part of the water

- Q: Air compressor high temperature, how's going on?

- Radiator block. When the air compressor ambient dust is large, long-term operation will cause the compressor radiator appearance adhesion of a layer of dust or oil, and the internal structure is due to accumulation of grease blockage, affect the cooling effect.

- Q: Can 3 or air conditioning air compressor make 20MPA air pressure?

- No, I suggest you do not play with fire, this small compressor compressor manufacturers throughout the country, Shanghai Oriental Compressor Factory production model is vf-206, you can consult

- Q: What happens when the air compressor is plugged in and does not work?

- If the above is normal, that is the motor above the two capacitors, one of the boot capacitor is broken, change a new one can.

- Q: What does air compressor load and unload mean?

- In general, the loading and unloading control changes the pressure of the compressed gas from Pmin to Pmax. Pmin is the minimum pressure to ensure that users work properly, also known as minimum pressure. The conversion relationship between Pmax, Pmin such as the formula: Pmax = (1 + 8) Pmin, which is a parameter in the 10% ~ 25% percentage. When we use the variable frequency speed regulation technology to realize the continuous adjustment of air supply, then the pipe network pressure will be maintained near the minimum pressure value Pmin.

- Q: What is the difference between air compressor water cooling, oil cooling and air cooling?

- I only know that air cooling and water cooling have not been heard. Air-cooled low cost, easy to use, but not suitable for long-term operation, minicomputers generally use this. Water cooling to the water pipe, making the pool, more trouble, but this machine can adapt to long-term operation, 365 days a year, 24 hours, full load operation is OK, the premise is no trouble on the way, huh, huh. The price is generally higher than the air-cooled

- Q: Y Series Motors 315-4 rotor shaft need how many tons of hydraulic press to pressure out?

- My unit is a 100 ton press

- Q: Is the air compressor good?

- The mountain air compressor is a product operated by the Zhejiang mountain water compressor of. Mountain air compressor quality is good, no matter from the quality, or use, are relatively perfect.

Send your message to us

Automatic Melamine Plywood Plate Hot Press Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches