Auto Bamboo Plywood Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Auto bamboo plywood board furniture manufacturing machinery

Products detail

Auto bamboo plywood board furniture manufacturing machinery is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Auto bamboo plywood board furniture manufacturing machinery is availale according to your requirements!

Features

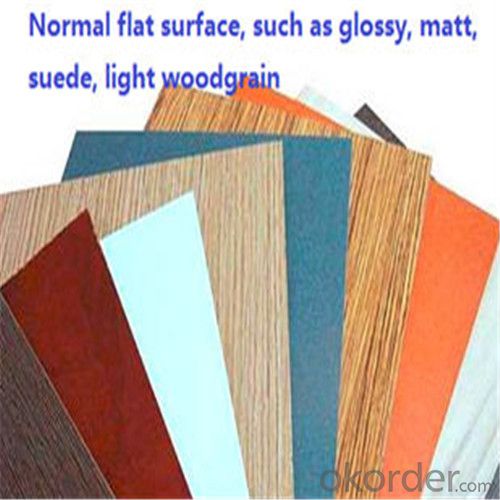

Auto bamboo plywood board furniture manufacturing machinery is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Auto bamboo plywood board furniture manufacturing machinery are for)

Auto bamboo plywood board furniture manufacturing machinery for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Auto bamboo plywood board furniture manufacturing machinery will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What is the brand of woodworking air compressor?

- Brand: Atlas, Ingersoll Rand, Fusheng, Sullair, Hitachi;

- Q: How can the water in a large air compressor pipe be completely removed?

- The main source of water in the air compressor pipe is that the air is compressed and heated at high temperature. It passes through the pipeline and cools slowly. The water molecules in the air condense and become condensed water. There are many ways to solve condensed water in compressed air.

- Q: What is the minimum power of screw air compressor?

- The screw air compressor adopts a complete set of configuration, only a single power supply connection and compressed air connection, and a built-in cooling system, which greatly simplifies the installation work. Screw type air compressor provides high quality compressed air for all walks of life because of its high efficiency, high efficiency, maintenance free and high reliability.

- Q: What is an air compressor for?

- The air compressor is used for the whole train for the wind because of the wind in order to implement the friction braking electro pneumatic braking conversion is 6KM per hour that do not rely on friction braking on electric braking is impossible for parking there is emergency braking is pure friction brake control of air compressor blower to air cylinder in total there are two low pressure cylinder and a high pressure cylinder air suction pressure even after 2 cooling filter program total wind cylinder through the wind pipe hose cock transmitted to the brake shoe hold the wheel in order to implement the tile friction brake air compressor fault is not full column before the gate time west of Tiananmen or Xidan that this is slipping there do not understand ask me again

- Q: What are the characteristics of a screw compressor?

- Working flow of double screw air compressorThe air through the air intake filter dust in the atmosphere or filtering impurities, the inlet control valve into the compressor, mixing and cooling lubricating oil injection in the compression process, by mixing the compressed gas separation tank from the compression chamber into the oil and gas, oil and gas compression at discharged through collision, interception, gravity the vast majority of the oil medium are separated, and then enter the oil and gas separator for fine separating two times, get little oil content of compressed air, when the air is compressed to the set pressure value, the minimum pressure valve open, compressed air is discharged into the cooler, and finally into the system.

- Q: The difference between BLT and BLX for screw compressors

- That's the problem of high and low allocation. BLT's accessories are a little better. Buy BLT better if you don't have any money. Buy BLX, then choose a PM series, permanent magnet motor, energy saving a lot. Now in press, are permanent magnet conversion better.

- Q: What are the contents of the maintenance of air compressor?

- Before or after each day of operation:(1) oil and gas bucket drainage;(2) check the oil level(3) prepare the peripheral equipment, such as sending water to power, opening the compressor outlet valve, etc.

- Q: What's the difference between screw compressor and scroll compressor?

- The scroll air compressor, which is a displacement type rotating machinery, uses the scroll rotor to mesh with the scroll stator to form a plurality of compression chambers. With the translation and rotation of the scroll rotor, the volume of the compressed chambers changes constantly, and the suction and compression of the gas are realized

- Q: Type of hydraulic press

- Speak tonnage! Specific models have those, manufacturers are not the same. 100 tons, 200 tons, 315 tons, 630 tons and so on! Now it is designed according to the customer's needs! "SHP-27-800A-SM" like our home equipment: 96 series, 27 series, 72 series, 98 series, 25 series, 35 series, 34 series, 79 series, and so on, do not say that much, it is a name

- Q: Dry sprinkler system and the pre action what specific differences. Pre acting without air compressor can not.

- The pre acting automatic sprinkler system refers to the closed water system which is not filled with water in the quasi working state. The fire alarm system is turned on by the automatic fire alarm system, and then converted into a wet system.

Send your message to us

Auto Bamboo Plywood Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords