Auto Particle Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Auto particle board furniture manufacturing machinery

Products detail

Auto particle board furniture manufacturing machinery is applicable for panel/ furniture plant or wood-based further processing to laminate decoration paper on particle board, MDF board with advanced technology.

Auto particle board furniture manufacturing machinery is availale according to your requirements!

Features

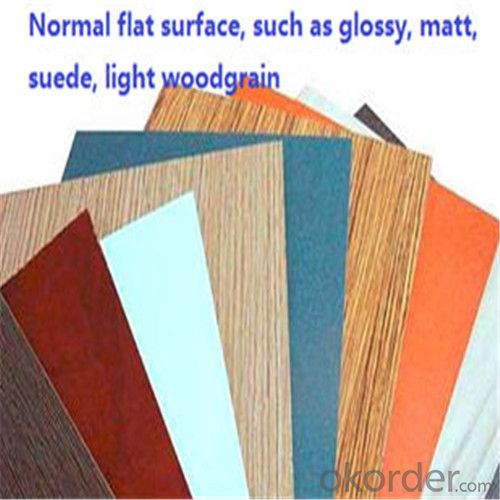

Auto particle board furniture manufacturing machinery is used to produce laminate board with a wide array of texture, from flat surface to light/deep emboss or synchronized grain engraving effects.

It is also suitable for laminating decorative paper,wearable paper and balance paper in both sides of HDF board to produce laminate flooring.

The applications (Auto particle board furniture manufacturing machinery are for)

Auto particle board furniture manufacturing machinery for Laminating furniture board.

- The covering materials are melamine paper, veneer etc.

- The core boards are MDF / HDF / Particle Board.

Products display

Packing & Shipping

Package:Auto particle board furniture manufacturing machinery will be packed according International MDF board hot press machine standard packing

Delivery : about 15 days after receive deposit payment

Certifications

FAQ

Q:What is the material of your products?

A:The main material are steels, oil cylinder and other. We can also choose material as customers’ requirement.

4.Q:How can I kown more about the press machine?

A: We are honored to send you some pictures and vedio about our machine. And we welcome every customer visit our factory.

5.Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ZDHY, ISO9001 authentication.

- Q: What are the factors that affect the air compressor exhaust?

- When the air filter is blocked or the resistance increases, the suction pressure of the compressor is reduced. When the outlet pressure is constant, the exhaust is reduced. The obstruction or resistance of intercooler is increased, which results in less exhaust. The management of air separation equipment is blocked, the increase of the resistance or the failure of the valve cause the compressor to increase the exhaust pressure, resulting in the rise of the pressure ratio and the decrease of the exhaust. The seal is not good, resulting in gas leakage, resulting in less exhaust. The cooler leakage, if a leakage of cooling water into the gas side channel, and is entrained into the impeller and diffuser, causing fouling, clogging the air flow is reduced, and if the two or three level leakage, compressed air will leak into the cooling water run, will reduce the amount of exhaust gas. The pressure of steam turbine (power frequency or voltage drop), caused by speed decreased, reducing the amount of exhaust gas. And any level of suction temperature, gas density decreases, can also cause the suction decreases

- Q: How can the air compressor be more convenient to drain water?

- Method of air compressor drainage more convenient: air compressor itself with automatic drainage device, usually by a "overflow ball" in the form of automatic drainage: overflow ball collection drainage, when the collection quantity reaches a certain value (such as overflow capacity 2/3 ball), automatically open the discharge valve for drainage.

- Q: The working principle and common troubles of screw compressor.

- 1. Check the contact and insulation resistance of the electric parts of the screw compressor;2, change the motor grease (every 8000 hours running change once), such as equipment specifications have parameters, the manual shall prevail;3 、 cleaning the reducing valve (intake valve);4. Clean the minimum pressure valve (pressure maintenance valve);Five 、 check valve for cleaning and returning oil;Six 、 cleaning temperature control valve;7. Clean the cooler;8. Clean the water separator;9. Correct all parameters. Note: the above maintenance shall be carried out after the equipment is confirmed free of electricity and pressure.

- Q: What accessories does the air compressor contain?

- Screw compressor parts for you to say ten, minimum pressure valve, air intake valve, check valve, oil off valve, control panel, air filter, oil core. Temperature control valve, cooler, pressure sensor, temperature sensor and so on

- Q: What flow meter can measure the flow rate when the air compressor is loaded and unloaded?

- Moreover, the display directly shows the standard flow rate of the air compressor at this time, so that it is convenient for the customer to monitor the production capacity of the air compressor in real time, such as problems, so that the technology can be found. Hefei - meter Comay Czech is very happy for you to answer the expert.

- Q: Does the gas separator of the air compressor belong to special equipment? Is it only necessary to provide the quality supervision and inspection report?

- Special equipment is the safety of life, the risk of large boilers, pressure vessels (including gas cylinders, the same below), pressure piping, elevator, crane, passenger ropeway, large recreation facilities and field (plant) in special vehicles. Among them, boilers, pressure vessels (including gas cylinders), pressure pipes for pressure type special equipment; elevators, lifting machinery, passenger ropeway, large recreational facilities for mechanical and electrical special equipment. In November 2014, AQSIQ announced the newly revised catalogue of special equipment.

- Q: The difference between BLT and BLX for screw compressors

- Equipped with low, BMW 7 series and BMW 5 Series difference

- Q: What is the working principle of air compressor?

- According to the working principle of air compressor can be divided into the compressor, compressor speed, volume of the compressor working principle is the volume of compressed gas, the gas molecules in the unit volume density increased to increase the pressure of compressed air;

- Q: Composition of air compressor

- Waterway circulation systemThe cooling water through the pipe into the air compressor intercooler for a gas compressing and discharging the cooling, then after entering the cooler for cooling the exhaust, another way of cooling water inlet pipe through two sets of heat exchanger cooling motor windings and the upper part of the main motor, the way of oil cooler for cooling.

- Q: Is the air compressor good?

- The air compressor is the base of product of modern industry, electrical and automation is often said that there is full pneumatic meaning; and the air compressor is to provide power source, pneumatic system is the core equipment of electromechanical drainage main source device, it is the prime mover (usually motor) into mechanical energy conversion device of gas pressure can, is the pressure of compressed air generator.

Send your message to us

Auto Particle Board Furniture Manufacturing Machinery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords