Self-adhesive Bitumen Waterproof Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

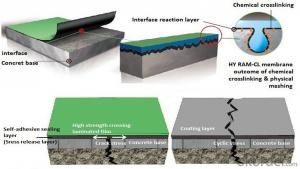

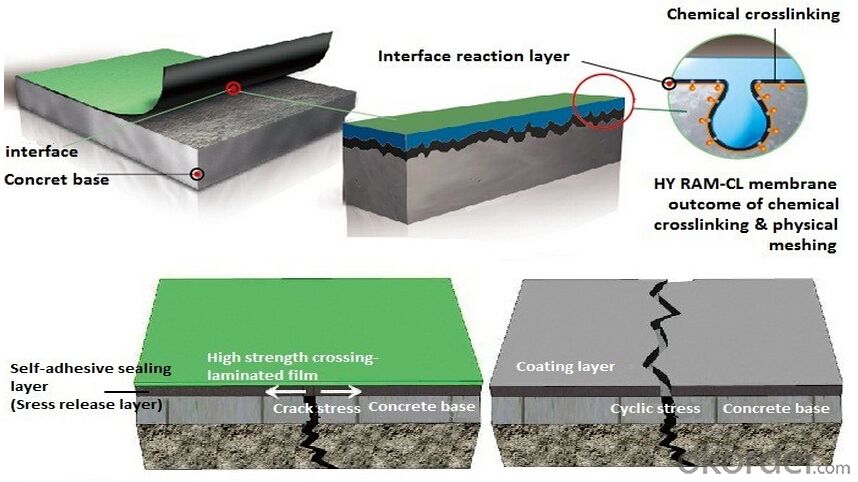

Introduction Self-adhesive Bitumen Waterproof Membrane CMAX:

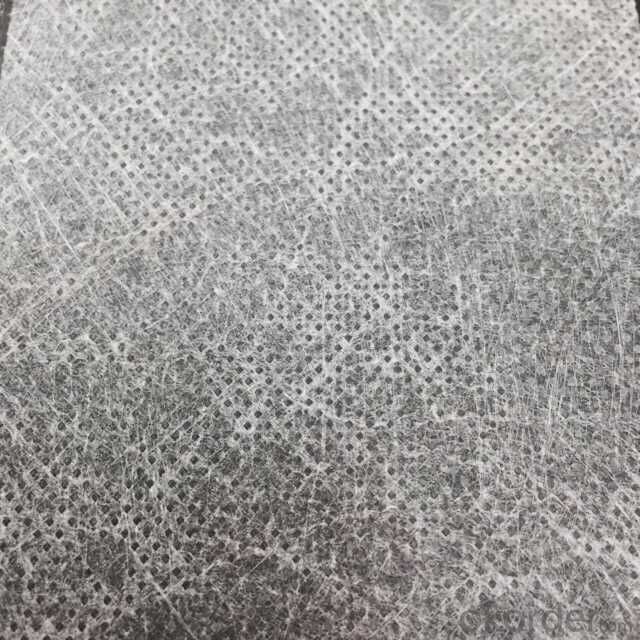

SBS(Styrene Butadiene Styrene) /APP (Atactic Polypropylene) modified bitumen membrane is made by saturating the base in bitumen, or thermoplastic elastomer (such as SBS, APP, APAO, APO), reinforced with polyester or fiberglass, finishing the upward face with polythene membrane, fine sands or mineral slates (or grains) or etc.

Specification Self-adhesive Bitumen Waterproof Membrane CMAX:

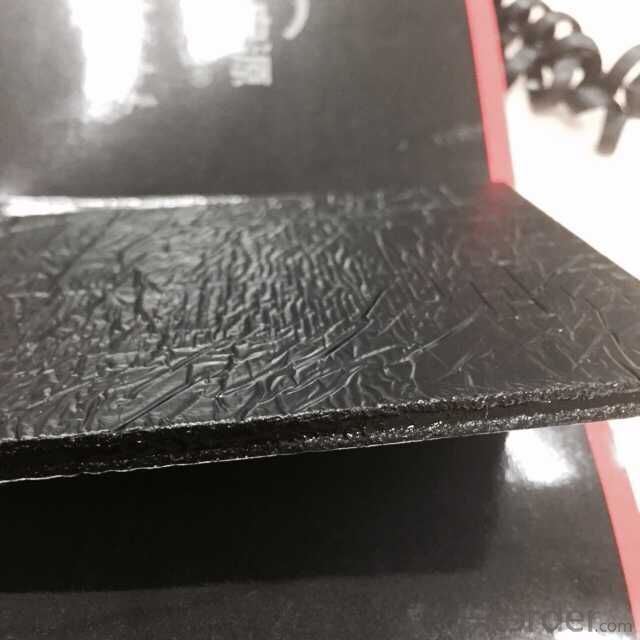

Thickness | 3mm, 4mm, 5mm |

Width | 1m |

length | 7.5m, 10m, 15m, or on demand |

Base | Polyester or Fiberglass felt |

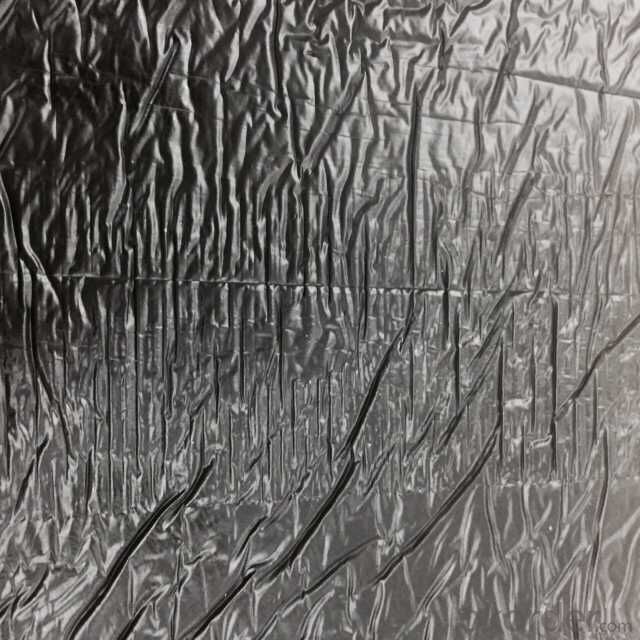

Surface | PE film, Aluminum foil, Yellow sand, Shale gravel(Schist), colored sand |

Type | could self-adhesive |

Notice | SBS modified bitumen membrane is specially applied in the cold district, APP modified bitumen membrane is more suitable for hot district with high temperature. could be self-adhesive modified bitumen membrane |

Applications Self-adhesive Bitumen Waterproof Membrane CMAX:

-Roof and underground in industrial and civil buildings;

-Bridge, subway, tunnel, swimming pool, etc.

-Waste landfill, sewage plant, irrigation system, etc.

-Self-adhesive Modified Bitumen Waterproof Membrane

-Easy applying and economic on the cost saving

Advantage Self-adhesive Bitumen Waterproof Membrane CMAX:

-Non-solidified, excellent elastic deformation,thus have good noise reducing;

-Easy applying and economic on the cost saving.

-Good performance on waterproof and economic sound damping.

Picture Self-adhesive Bitumen Waterproof Membrane CMAX:

Storage Self-adhesive Ridge Ventilation Membrane for Roofing:

Shelf life is 12 months. Store in a cool and dry place with original packing.

Breathable Waterproof Roof Underlay membrane (PP-PP,S-PP,S-S)

Permeable membrane is polymer modified asphalt based, with surface of high strength polypropylene fiber. Back side coated with self adhesive glue or antiskid sand. Made by special process. With excellent waterproof performance and breathable properties.\

Description | Specification | Width | Length | Thickness | |

Roof underlay | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

Roof underlay with adhesive band | 500g/m2PP—PP | 1000mm | 30m | 0.8mm | |

600g/m2S—PP | 1000mm | 25m | 1.0mm | ||

1500g/m2S—S | 1000mm | 20m | 1.3mm | ||

It is used as the underlayment of cement tile, painted pottery watts and asphalt shingle. Also suitable for all kinds of architectural roofing, walls, underground waterproof and damp proof project.

Features:

It has good waterproofing and ageing-resistance function,not flowing at highest temperature and no crack at lowest temperature;

Easy application,no pollution,and long service life etc.

Usage:

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs,basements,toilets etc;and the waterproofing of bridges,parking area,tunnels,reserviors etc.

It is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions.

Requirements for surroundings

-The base should be dry and clean. Do not work in the rainy or snowy day.

-Do not work under heavy wind(above 5 grade)

-Unsuitable for construction below 0°C

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used in bathrooms?

- Yes, a waterproofing membrane can be used in bathrooms. In fact, it is highly recommended to use a waterproofing membrane in bathrooms to prevent water damage and leakage. The membrane acts as a barrier, preventing moisture from seeping into the walls or floors, ensuring the longevity and durability of the bathroom.

- Q: Can a waterproofing membrane be used on chrome surfaces?

- No, a waterproofing membrane is not suitable for use on chrome surfaces as it is designed to be used on porous materials such as concrete or wood to prevent water penetration. Chrome surfaces are already water-resistant, so applying a waterproofing membrane would be unnecessary and may damage the chrome finish.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Concrete surfaces can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to create a barrier against water penetration. They are often employed on concrete surfaces to safeguard them against water damage. Typically, these membranes are composed of rubber, PVC, or bitumen and can be applied to the concrete surface either in a liquid or sheet form. Once applied, the membrane forms a strong and continuous waterproof layer that effectively prevents water from seeping into the concrete. This proves to be particularly advantageous in areas that frequently come into contact with water, such as basements, bathrooms, or outdoor concrete structures. By preventing water-related issues such as cracking, spalling, or mold growth, waterproofing membranes effectively prolong the lifespan of concrete surfaces.

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can differ depending on various factors. These factors include the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care given to the membrane. Typically, waterproofing membranes designed for extreme weather conditions can last 20-30 years or more if they are of high quality. These membranes are usually made from durable materials like modified bitumen, PVC, EPDM, or TPO. These materials are specifically engineered to endure harsh weather elements. It is worth noting that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can speed up the deterioration of the membrane. For instance, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. To extend the lifespan of the waterproofing membrane in extreme weather conditions, regular maintenance and inspections are crucial. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better shielded against the harsh effects of extreme weather. Moreover, proper installation techniques and adherence to the manufacturer's guidelines are vital for ensuring the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can significantly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can endure extreme weather conditions for several decades, it is important to regularly monitor its condition, provide proper care and maintenance, and promptly address any issues that arise in order to maximize its lifespan.

- Q: SBS modified asphalt waterproofing membrane and synthetic polymer membrane the same, not the same, what is the difference?

- SBS modified asphalt waterproofing membrane is a kind of high-polymer modified asphalt waterproofing membrane, high polymer modified asphalt waterproofing membrane is synthetic polymer modified asphalt coating layer,

- Q: Can a waterproofing membrane be used for fire pit areas?

- No, a waterproofing membrane should not be used for fire pit areas. While waterproofing membranes are designed to prevent water penetration, they are not designed to withstand the high temperatures and potential fire hazards associated with fire pits. Fire pit areas require specific fire-resistant materials that can withstand the heat generated by the fire and prevent any potential fire accidents. It is important to use appropriate materials that are specifically designed for fire pit areas to ensure safety and prevent any potential damage.

- Q: Can a waterproofing membrane be used for planter boxes or green roofs?

- Certainly, planter boxes or green roofs can benefit from the utilization of a waterproofing membrane. It is strongly advised to implement a waterproofing membrane in these scenarios in order to avoid any water seepage or harm to the underlying structure. Essentially acting as a safeguard, the waterproofing membrane serves to prevent water infiltration into the planter boxes or green roofs, therefore preventing potential complications like decay, mold, or structural deterioration. By skillfully sealing the area, the waterproofing membrane guarantees that the water remains within the designated area, which in turn fosters robust plant growth and safeguards the structural stability.

- Q: Can a waterproofing membrane be used in parking garages?

- Parking garages can benefit greatly from the use of a waterproofing membrane. Due to their exposure to various weather conditions and heavy vehicular traffic, these structures are susceptible to moisture infiltration and structural damage. Therefore, it is crucial to install a dependable waterproofing system to safeguard against water penetration and potential deterioration. A waterproofing membrane serves as an effective solution for parking garages by acting as a barrier against water and moisture. It is typically composed of durable materials such as modified bitumen, PVC, or EPDM, which are resistant to water intrusion. When applied to the concrete surface, the membrane forms a protective layer that prevents water from seeping through. By preventing moisture from penetrating the concrete, the waterproofing membrane not only defends the parking garage against water infiltration but also helps to prolong its lifespan. This, in turn, reduces the risk of corrosion, deterioration of reinforcing steel, and the formation of cracks. Ultimately, the structural integrity of the parking garage is maintained, saving on costly future repairs or replacements. Moreover, a waterproofing membrane can offer additional advantages, including resistance to chemicals, UV radiation, and abrasion. This makes it an ideal solution for parking garages that face harsh environmental conditions and heavy traffic. To summarize, the use of a waterproofing membrane is highly recommended for parking garages. It provides reliable protection against water infiltration, helps to maintain the structure's integrity, and extends its lifespan.

- Q: Can a waterproofing membrane be installed on curved surfaces?

- Yes, a waterproofing membrane can be installed on curved surfaces. There are various types of waterproofing membranes available in the market that are specifically designed to cater to different surface shapes and conditions. These membranes can be flexible and easily molded to fit curved surfaces, ensuring effective waterproofing even on complex structures. However, it is important to consult with a professional or manufacturer to determine the most suitable membrane and installation technique for your specific curved surface to ensure proper adhesion and long-lasting waterproofing.

- Q: What are the different thickness options for a waterproofing membrane?

- Waterproofing membranes are available in a range of thicknesses to accommodate different needs and uses. Typically, the thickness of a waterproofing membrane can vary from 0.5 mm to 2.0 mm. For applications that require a flexible and lightweight solution, thinner waterproofing membranes, measuring between 0.5 mm and 0.8 mm, are often utilized. These membranes are commonly employed in residential waterproofing projects, such as roof decks, balconies, and basements. Additionally, they are suitable for areas with minimal foot traffic or limited space, as their thin profile allows for easy installation and minimal disruption to the existing structure. In both residential and commercial applications, medium-thickness waterproofing membranes, ranging from 1.0 mm to 1.5 mm, are frequently used. These membranes offer a balance between flexibility and durability, making them appropriate for areas that may experience moderate to heavy foot traffic or require additional protection. Common areas of application include shower enclosures, wet rooms, and exterior walls. Thicker waterproofing membranes, typically measuring 1.5 mm to 2.0 mm, are often preferred for high-demand applications or areas exposed to extreme conditions. These membranes provide enhanced strength, resilience, and resistance to punctures and abrasions. They are commonly utilized in industrial settings, commercial buildings, and civil engineering projects, such as tunnels, bridges, and parking structures. It is important to note that the appropriate thickness option for a waterproofing membrane depends on specific project requirements, including anticipated usage, exposure to moisture, and expected loads. Therefore, it is advisable to consult with a professional or manufacturer to determine the most suitable thickness option for a particular application.

Send your message to us

Self-adhesive Bitumen Waterproof Membrane CMAX

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords