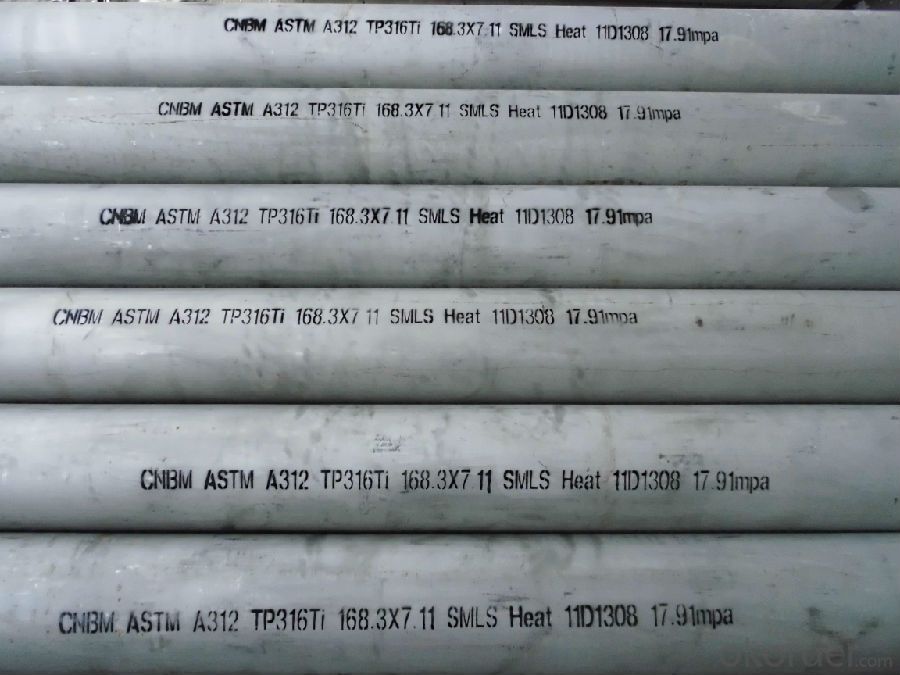

Seamless tube316Ti 10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

316Ti stainless steel plate is the addition of Ti in SUS316 steel can improve the resistance to intergranular corrosion resistance.

The chemical composition of 316Ti stainless steel:

C (%): less than 0.08

Si (%): less than 1

Mn (%): less than 2

P (%) is less than or equal to: 0.045

S (%) is less than or equal to 0.03

Cr (%): 16 ~ 18

Ni (%): 10 ~ 14

Mo (%): 2 ~ 3

other (%):

5 (C+N) = Ti = 0.70, N = 0.10

The mechanical properties of 316Ti stainless steel:

YS (Mpa) = 205 TS (Mpa) = 520 EL (%) is more than or equal to 40 Hv 200 degrees

- Q: Are stainless steel pipes suitable for fertilizer industries?

- Fertilizer industries find stainless steel pipes to be suitable. Stainless steel possesses a high level of corrosion resistance, a crucial characteristic for industries where pipes regularly encounter corrosive substances like fertilizers. Moreover, stainless steel pipes exhibit exceptional strength and durability, enabling them to withstand the demanding conditions of fertilizer production. Their smooth inner surface prevents the accumulation of sediments and impurities that might compromise fertilizer quality. Additionally, stainless steel pipes are effortless to clean and maintain, meeting the hygiene and safety standards mandated by the fertilizer industry. All in all, stainless steel pipes are an outstanding choice for fertilizer industries due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q: Are stainless steel pipes suitable for wastewater treatment plants?

- Indeed, wastewater treatment plants find stainless steel pipes to be quite suitable. The reason lies in the fact that stainless steel boasts remarkable resistance to corrosion, a quality of utmost importance in an environment where wastewater might house aggressive chemicals and substances. Not only can stainless steel pipes withstand the elevated temperatures and pressures commonly present in wastewater treatment plants, but they also prove to be a long-lasting and dependable option. Furthermore, the ease with which stainless steel pipes can be cleaned and maintained further diminishes the likelihood of contamination during the treatment process. Hence, the durability, corrosion resistance, and ease of maintenance that stainless steel pipes offer have made them a favored choice for wastewater treatment plants.

- Q: How do you measure the thickness of a stainless steel pipe?

- One common method to measure the thickness of a stainless steel pipe is by using a caliper or a micrometer. These tools allow you to accurately measure the outer diameter and inner diameter of the pipe. By subtracting the inner diameter from the outer diameter, you can determine the wall thickness of the pipe.

- Q: Are stainless steel pipes suitable for industrial applications?

- Yes, stainless steel pipes are highly suitable for industrial applications. They possess excellent corrosion resistance, high strength, and durability, making them ideal for handling various fluids and gases in industrial settings. Additionally, stainless steel pipes can withstand high temperatures and pressure, making them reliable for demanding industrial processes.

- Q: Are stainless steel pipes suitable for mining operations?

- Yes, stainless steel pipes are suitable for mining operations. They offer excellent durability, corrosion resistance, and high strength, making them ideal for transporting various materials and fluids in harsh mining environments. Stainless steel pipes can withstand extreme temperatures, pressure, and exposure to chemicals, ensuring reliable and long-lasting performance in mining operations.

- Q: How do stainless steel pipes compare to copper pipes?

- Stainless steel pipes are generally more durable, corrosion-resistant, and can withstand higher temperatures compared to copper pipes. Additionally, stainless steel pipes have a longer lifespan and require less maintenance. However, copper pipes have better heat conductivity and are easier to install. The choice between stainless steel and copper pipes depends on the specific application and requirements.

- Q: Are stainless steel pipes suitable for chemical reactors?

- Yes, stainless steel pipes are suitable for chemical reactors. Stainless steel is known for its excellent corrosion resistance properties, making it an ideal choice for handling various chemicals and acids in a reactor system. Additionally, stainless steel pipes offer high strength, durability, and heat resistance, ensuring safe and efficient operation in chemical processes.

- Q: Can stainless steel pipes be used for underground water supply lines?

- Yes, stainless steel pipes can be used for underground water supply lines. Stainless steel is highly resistant to corrosion, making it an ideal choice for underground applications where the pipes may come in contact with soil, moisture, and other corrosive elements. It also has excellent strength and durability properties, ensuring that the pipes can withstand the pressure and stress of being buried underground. Furthermore, stainless steel is a hygienic material that does not leach any harmful substances into the water, making it safe for drinking water supply lines. Overall, stainless steel pipes are a reliable and long-lasting option for underground water supply lines.

- Q: Are stainless steel pipes suitable for extreme temperatures?

- Indeed, extreme temperatures are well-suited for stainless steel pipes. Renowned for their exceptional heat resistance properties, stainless steel is a favored choice for applications involving elevated temperatures. With the ability to endure both exceedingly high and low temperatures, stainless steel pipes prove their suitability across a broad spectrum of industries, including oil and gas, chemical processing, power generation, and aerospace. The high levels of chromium and nickel found in stainless steel alloys significantly contribute to their resistance against corrosion and oxidation, allowing them to maintain their structural integrity even in the face of extreme temperature conditions. Furthermore, stainless steel pipes exhibit minimal expansion and contraction rates, ensuring their resilience against thermal cycling without any notable distortion or harm. In summary, stainless steel pipes stand as a dependable and long-lasting option for managing extreme temperatures.

- Q: What are the common sizes of stainless steel pipes?

- The sizes of stainless steel pipes commonly differ based on their intended use and industry standards. However, a range of sizes are commonly found, including 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, 1 inch, 1 1/4 inch, 1 1/2 inch, 2 inch, 2 1/2 inch, 3 inch, 4 inch, 5 inch, 6 inch, 8 inch, 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 24 inch, and 36 inch. These sizes are typically determined by the outside diameter (OD) of the pipe. It is important to acknowledge that slight variations in these sizes may occur depending on the specific standards followed by the manufacturer or industry.

Send your message to us

Seamless tube316Ti 10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches