Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

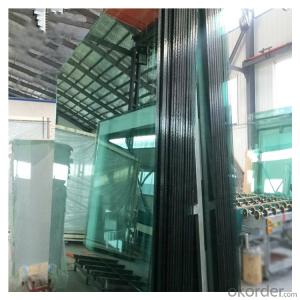

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Glass

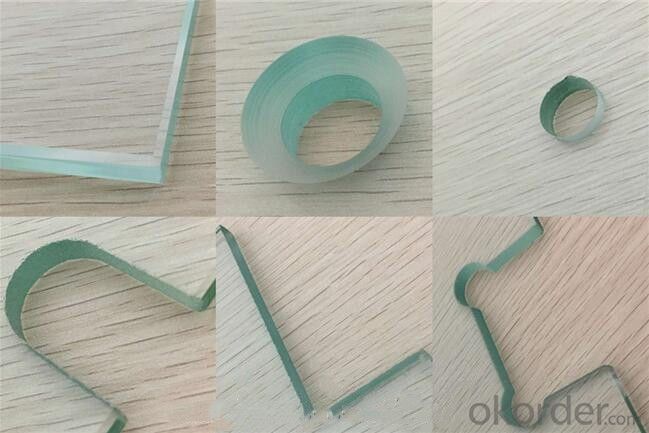

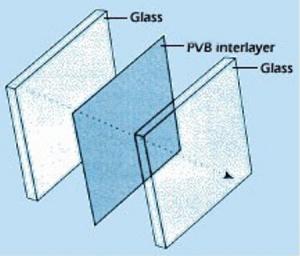

Laminated glass is composed of two or more pieces of glass, sandwiched between a layer or multiple layers of organic polymer intermediate film, through special high temperature precompression (or vacuum) and high temperature and high pressure process, so that the glass and intermediate film permanent bonding as one of the composite glass products.

Specification

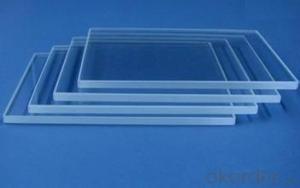

Single Layer Glass Thickness: 3-25mm

Max. Size: 3000*16000mm

Min Size: 100x300mm Interlayer: PVB, SGP, EVA, Sefar, Decoration Film, mesh etc.

Character:

A glass floor is a stunning, dramatic addition to any interior space. Not only does our glass flooring offer aesthetic appeal, but it also allows for light to flow into the space below. The unique benefits of CNBM glass flooring continue with its superior, rigorously tested framing system and its exceptional engineering support and design flexibility. With a beauty and simplicity that can’t be matched, Glass Flooring Systems’ interior system is the perfect solution for any glass-flooring project.

Our triple-laminated glass assembly is engineered for passive redundancy with panels that are fabricated using three layers of low-iron, tempered glass with structural PVB, SGP interlayers. Our structural glass delivers exceptional safety and design flexibility, with the top layer consisting of a safe, non-slip surface that allows light to filter into the space below. This layer can also serve as a form of artistic expression, with dozens of patterns, textures, and finishes that meet or exceed the ASTM safety standards. The role of the interlayers is to bond the layers of glass together to assure the safety and structural integrity of every glass flooring system we produce.

Advantage:

Our glass-flooring system comes standard with a variety of innovative features and options that give it distinct advantages over its competitors:Low-iron glass is standard with all our glass-flooring products;If you need, we can also provide proprietary 6063-T6 aluminum extrusions that produce crisp, clean profiles;Fully tested, anti-slip textures;Pre-engineered and custom sizes for ease of integration;

Packing and Shipping:

- Q: What chemicals can be made from glass, paper, detergents, etc?

- Glass: quartz, sodium carbonate, calcium carbonate paper: bark is enough.. cellulose + bleaching agent, such as activated carbon and other detergents, soap bar, sodium stearate

- Q: What is the difference between white float glass and ordinary float glass?

- Ultra white is generally used in solar panels, raw materials, aluminum content higher

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- General purchases of raw materials are their own, the general yacht above the bottom of the ship is a manufacturer, the ship is also a cloth manufacturers, as well as small boats on the yacht is also a manufacturer

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The main are: quartz sand. And soda ash.

- Q: What are the main materials for making glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor* basic materials for glass making

- Q: What's the difference between plexiglass PS boards and toughened glass? What's the difference between them?

- Organic glass is made of polymer materials, which belongs to engineering plastics, PS material is polystyrene board, tempered glass is the glass rapid heating and cooling. The price should be obtained after the glass is the most expensive, followed by PS, organic glass is the most expensive, but after two the advantage is not broken.

- Q: What is quartz made of?

- Applications and uses of 1 quartz glass, flat glass, float glass, glass (glass jar, glass bottle, glass tube), the main raw material of optical glass, glass fiber, glass, conductive glass, glass cloth and anti ray special glass 2, ceramics and refractories embryo material and porcelain glaze, the furnace with high silica, ordinary brick raw materials such as silicon carbide 3, metallurgical silicon metal, ferrosilicon alloy and silicon Aluminum Alloy and other raw materials or additives, flux

- Q: Is flat glass the main material or structural component in raw materials?

- But sometimes the structural parts, such as the exhibition hall and the hall, have a transparent floor beneath which the contents are displayed. In order to save the raw materials, they may be designed to be cut from the whole glass without cutting into the box. At this time the flat glass is load-bearing components, to calculate its carrying capacity, which is the structural components of the.

- Q: What is the raw material of glass?.

- 1. the main raw material of glass(1): the main component of silica sand or borax borax glass is introduced into silica or silica or boron oxide, which alone can melt into a glass body in the combustion, determines the main properties of glass, appropriately called silicate glass or borosilicate glass.(2): the main ingredients of soda soda or salt and mirabilite into glass is sodium, they can with silica sand and other acidic oxides formed in the fusible salt calcination, the fluxing action, the glass is easy to mold. But if the content is too much, the thermal expansion rate of glass will increase, and the tensile strength will decrease.(3) limestone, dolomite, feldspar, etc.: the main component of limestone introduced into glass is calcium oxide, which enhances the chemical stability and mechanical strength of glass. But the content is too much, which makes the glass break and reduce the heat resistance.As a raw material for introduction of Magnesium Oxide, dolomite can improve the transparency of glass, reduce thermal expansion and improve water resistance.Feldspar, as a raw material for introduction of alumina, can control the melting temperature and increase durability. In addition, potassium feldspar can also provide components, improve the thermal properties of glass.(4) broken glass: Generally speaking, not all new materials are used in the manufacture of glass, but the broken glass of 15%--30%.

- Q: The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass according to PBO (lead oxide) content is divided into high (24%PBO and above), medium (18%PBO), low (12%-16%PBO) three grades. Grading standards are similar to gold. International standard crystal glass is 24%PBO, so merchants will also call this class "24K"". If you go to buy, say some similar "jargon", the other party will feel that you are more adept, encountered illegal businesses, nor dare to fool you.

Send your message to us

Safety Clear Tempered Laminated Glass Factory Price For stairs/floor/balustrade Glass

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches