Safety Toughened Clear And Tinted Tempered Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass:

We manufacture a wide range of glass to meet your different demands: Float glass, Tinted glass, Stained glass, Laminated glass, Mirror glass, Aluminum mirror, Silver mirror, Reflective glass, Online coated glass, Patterned glass, Figured glass, Wired glass, Colored glass, Tempered glass, Toughened glass, Safety glass, Shower doors glass, Emulsificated glass, Acid-etched glass, Obscure glass, Sandblasted glass, Solar glass, Ultra clear low iron glass, Low-E glass, Obscure glass, Glass block, Glass brick, Picture frame in different colors and sizes.

2.Main features of Glass:

1) Standard: CCC, intertek

2) 3 - 19mm float glass

3).Size: customized sizes available

4).tempered or silk

5).drill work available

6).Printing Furniture Glass ,Beautiful surface with good coverage.

Profiled glass, as your design and requirement

Type: clear, tinted, color glazed, coated, Low-E, IGU and laminated glass etc.

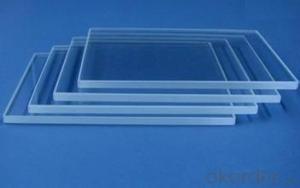

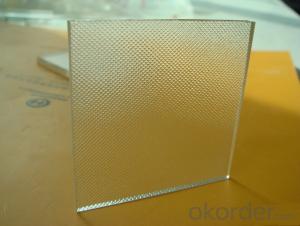

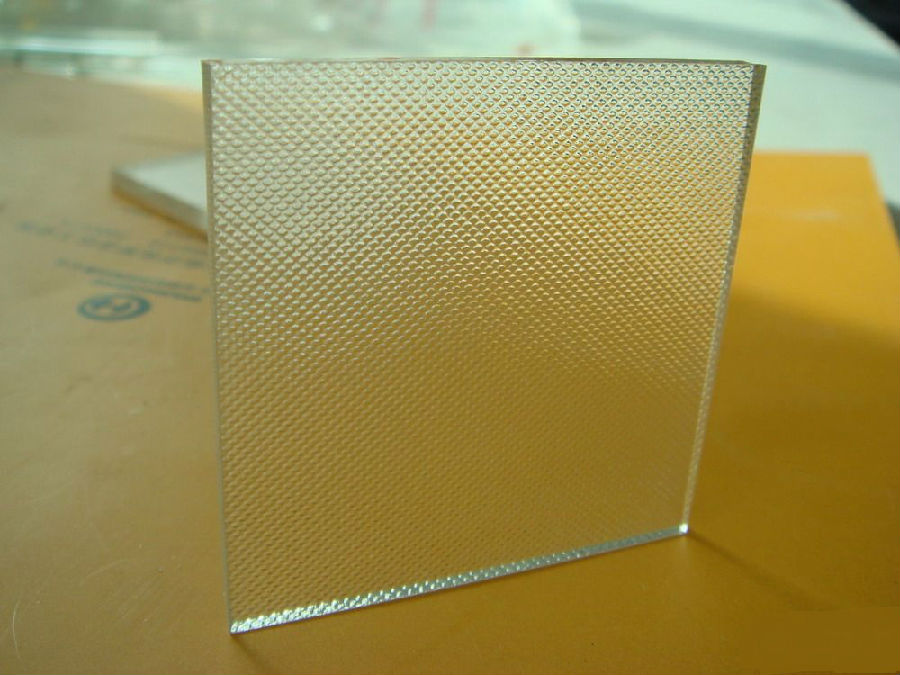

3.Glass Images:

4. Glass Technical Parameters:

CLEAR FLOAT GLASS

Thickness: 2mm-19mm

Sizes: 1524x2134mm, 1830x2440mm, 2140x3300mm, 2140x3660mm, 2250x3300mm, 3660x2140mm, 3660x2250mm etc.

EXTRA CLEAR GLASS

Thickness: 3mm-19mm

Sizes: 1830x2440mm, 2140x3300mm, 2140x3660, 2250x3300mm, 2250x3660mm etc.

TINTED GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Mist Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Ocean Blue, Pink etc.

Thickness: 3mm-12mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm, 2140x3660mm, 2250x3160mm etc.

REFLECTIVE GLASS

Colors: Euro Bronze, Golden Bronze, Euro Grey, Dark Grey, French Green, Dark Green, Lake Blue, Dark Blue, Pink, Silver etc.

Thickness: 3mm-10mm

Sizes: 1524x2134mm, 2140x3300mm, 2250x3210, 2250x3300mm etc.

MIRROR

Types: Silver Mirror, Aluminum Mirror, Copper and Lead Free Mirror, Safety Mirror, Solar Mirror and Beveled Mirror etc.

Thickness: 1.5mm, 1.8mm, 2mm, 2.7mm, 3mm, 4mm, 5mm and 6mm etc.

Sizes: 1524x2134mm, 1830x1220mm, 1830x2440mm, 2140x3300mm, 2250x3300 etc.

LAMINATED GLASS

PVB Color: Clear, Green, Blue, Bronze, Grey, Milk white etc.

Glass Color: Clear, French Green, Dark Green, Ford Blue, Dark Blue, Bronze, Euro Grey etc. Float glass and reflective glass are available.

Thickness: 3+0.38+3mm, 4+0.38+4mm, 5+0.38+5mm, 6+0.38+6mm, 3+0.76+3mm, 4+0.76+4mm, 5+0.76+5mm, 6+0.76+6mm etc. till to 42.3mm

Sizes: 1830x2440mm, 2140x3300mm etc.

PATTERNED GLASS

Thickness: 3mm, 3.5mm, 4mm, 5mm, 6mm and 8mm

Sizes: 1220x1830mm, 1524x2134mm, 1830x2440mm, 3300x2140mm etc.

Patterns: Aqualite, Bamboo, Beehive, Chinchilla, Crystal, Diamond, Flora, Karatachi, Masterlite, Millennium, Mistlite, Morgon II, Moru, Nashiji, Rain and Wanji etc.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What kind of material is glass made of?

- 1. isotropic particles of glass are arranged irregularly in general, but are statistically uniform, so that their physical and chemical properties are the same in any direction. The crystal is anisotropic. Examples: resistivity, thermal conductivity, transmissivity, refractive index, etc..2. there is no fixed melting point. Glass changes from solid to liquid and varies gradually over a range of temperatures. The crystal is determined by melting point, for example, (water ice crystals) in C melt 0 Eve joy. This property of glass makes it possible to be shaped by blowing, pulling, pressing, and other methods.3. tunability of composition and properties. The properties of the glass may vary continuously and gradually within a certain range with their properties. The crystal has a fixed component and a definite performance. In this way, we can adjust the composition of the glass, so that its performance meets the requirements of the use.

- Q: Chemical materials and additives needed for the production of glass

- 1. Blending of raw materials. The main ingredients of float glass are: 73% of silica, 13% of sodium carbonate, 9% of calcium oxide and 4% of magnesium. The ingredients are mixed in proportion, followed by the addition of small pieces of recycled glass.2. Melting of raw materials. The prepared material passes through a mixing bin and then goes into a kiln with 5 chambers and is heated at about 1550 degrees centigrade to become a molten glass. 3. Glass forming. Molten glass flows into a tin bath and floats over molten molten tin, at a temperature of about 1000 degrees celsius. The molten glass on the tin solution forms a glass band of 3.66 meters wide and a thickness of 3mm to 19mm. Because the glass and the tin are very different in viscosity, the molten glass at the top does not mix with the molten tin below, and forms very smooth contact surfaces.4. Cooling of molten glass. When the glass band leaves the bath, the temperature is about 600 degrees Celsius, then it enters the annealing chamber or the continuous cooling kiln, and the temperature of the glass is gradually reduced to 50 degrees celsius. Thus, the glass produced by the Xu cooling method is also called annealed glass. 5, cutting and storage. After the cold, the glass passes through several stages of quality inspection, then cut into different sizes for packaging, storage, storage or transportation.Quartz sand is a hard, abrasion resistant and stable chemical silicate mineral. Its main mineral composition is SiO2, the color of quartz sandFor the white, colorless or translucent, 7 hardness, brittle cleavage, conchatus fracture, oil sheen, density 2.65, bulk density (1-2.0 = 1.6), 20-200 was 1.5, the chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, the melting point of 1750 DEG C.

- Q: Method for cutting thick glass

- Mechanical cutting glass:Mechanical cutting glass is the mechanical property of glass with low tensile stress. The diamond or emery is used to cut the surface, and the force is cut off because of tension.(1) when glass cutters do not cut very thick glass, they use diamond glass cutters inlaid with diamond at the ends of brass and cut ordinary flat glass, and often use super hard knife wheels. In addition, when cutting, adding kerosene and other liquids, the incision and tool life are better protection. In addition, to lead the soft glass tube, but also useful to cut the file.(2) diamond saw cutting diamond saw is not limited to glass, but also widely used in the cutting of germanium, silicon, ceramics, crystal and so on. Compared with common grit or ordinary abrasive saw, diamond saw has high cutting efficiency. Generally, grinding fluid is used during cutting. The bonding materials of diamond saw include metal, thermosetting resin, ceramic and so on. But the metal saw such as brass is usually cut. The thickness of saw blade is about 0.2 ~ 7ram. Cutting method is divided into outer circle cutting, inner circle cutting and band saw cutting.

- Q: Who knows how the types of silicon sand are divided into types and what they are used for?

- The main raw material for making glass!! Simply means that the silicon containing sand, ordinary sand containing silicon. Generally, the sand with more silicon content is the good material for making glass. The technology of glass has been developed for more than 5000 years. It was not until twentieth Century that glass became an industrial material and developed rapidly.

- Q: What's good with a cup?

- Pure porcelain, porcelain, glass, these basic is non-toxic and good some of the porcelain. The problem is that plastic, buy when you should pay attention to:1. see, look at the material are impurities.2., smell, if there is a pungent odor, it is recommended not to buy. Attention to drinking hot water, this cup is very bad for the body.

- Q: What kind of material is the glass made of? Is the price relative to the quality?

- The main constituents of the glass are calcium silicate, sodium silicate and silicaExpensive and not expensive must be related to quality (at least with impurities)

- Q: What happens when toughened glass breaks?

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What material is used in the protective film in the middle of glass?

- The raw material glass membrane used in general is Japan's Asahi pin and domestic luoyang,

- Q: Use of glass flake cement

- Good temperature resistance. The use of glass scale lining, its heat resistance than similar resin coating can be increased by 20-40 degrees, so often used in oil pipelines, hot water pipelines, heat resistant chemical devices.

- Q: What's the difference between heat resistant glass and tempered / reinforced glass?

- Connaught licensing high borosilicate heat-resistant glassware with the new formulation, new technology, new technology, high strength, high temperature resistance, impact resistance, temperature change, not self advantages. With acid and alkali resistance, water resistance, high hardness, wear-resistant, easy to clean, should not knot stains, including harmful substances, and many other advantages, more close to the people's lives. The product is crystal clear, beautiful and practical. It is suitable for microwave oven, oven, refrigerator and so on. It can be cleaned by dishwasher through the 120 - meter shock resistance test. Can barbecue in microwave oven, absorb microwave very few, save energy, save electricity.

Send your message to us

Safety Toughened Clear And Tinted Tempered Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches