S600 Aluminum Coil Price 5052 Temper H32 0.4mm 0.5mm 0.6mm Thick Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5052 Temper H32 0.4mm 0.5mm 0.6mm Thick Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

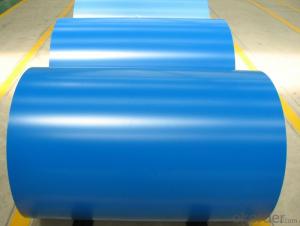

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: How are aluminum coils used in the production of sporting goods?

- Aluminum coils are used in the production of sporting goods primarily for their lightweight and durable properties. They are commonly used in the manufacturing of sports equipment such as baseball bats, tennis rackets, and bicycles. The coils are shaped, formed, and molded into the desired product, providing strength and flexibility while reducing overall weight. This allows athletes to have better control, enhanced performance, and reduced fatigue during sports activities.

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can buy flat sheet directly next time to avoid trouble.

- Q: Can aluminum coils be used in the production of aluminum facades?

- Yes, aluminum coils can be used in the production of aluminum facades. Aluminum coils are commonly used in the construction industry for various applications, including the production of facades. The coils are typically made from high-quality aluminum alloy, which offers excellent durability, corrosion resistance, and aesthetic appeal. The coils can be easily shaped, cut, and formed to create the desired design and size for the aluminum facades. Additionally, aluminum coils can be coated with different finishes, such as powder coating or anodizing, to provide further protection and enhance the appearance of the facades. Overall, aluminum coils are a versatile and reliable material for the production of aluminum facades, offering a wide range of design possibilities and long-lasting performance.

- Q: What is the minimum thickness available for aluminum coils?

- The minimum thickness available for aluminum coils can vary depending on the specific requirements of the application. However, in general, aluminum coils can be manufactured with a minimum thickness of around 0.006 inches or 0.15 millimeters. It is important to note that certain industries or uses may have different minimum thickness requirements, so it is always advisable to consult with a manufacturer or supplier to determine the appropriate thickness for a specific application.

- Q: Can aluminum coils be used for electrical conductors?

- Indeed, aluminum coils are capable of serving as electrical conductors. Aluminum, being a metal with exceptional conductivity, finds frequent utilization in electrical contexts. With electrical conductivity ranking second only to copper, aluminum proves to be a fitting material for the conduction of electricity. In numerous electrical apparatuses and setups like transformers, motors, generators, and power transmission lines, aluminum coils are commonly employed.

- Q: Just wondering if an aluminum and Fluoride bond can be created by boiling fluoridated water in aluminum cookware?

- i would say yes because ions are released from most things when heated

- Q: How are aluminum coils protected against corrosion?

- Various methods are utilized to protect aluminum coils from corrosion. One prevalent approach involves applying a protective coating or finish to the coil's surface. This coating acts as a barrier, preventing the aluminum surface from coming into contact with moisture, oxygen, and other potentially corrosive elements present in the surroundings. The coating can take the form of a layer of paint, anodizing, or a specialized protective film. Another technique employed to safeguard aluminum coils from corrosion is alloying. By incorporating small quantities of other metals such as copper or zinc into the aluminum, the corrosion resistance of the alloy is enhanced. These alloyed metals create a protective oxide layer on the aluminum's surface, serving as a shield against corrosion. In addition to coatings and alloying, proper cleaning and maintenance of aluminum coils are essential for corrosion prevention. Regular cleaning helps eliminate any contaminants or corrosive substances that may have accumulated on the coil's surface. This ensures the integrity and effectiveness of the protective coatings or oxide layers in preventing corrosion. Furthermore, the proper installation and sealing of aluminum coils are imperative for corrosion protection. Effective sealing prevents moisture or other corrosive agents from infiltrating the interior of the coil, which can result in corrosion over time. Overall, a combination of protective coatings, alloying, regular cleaning, and proper installation techniques plays a crucial role in safeguarding aluminum coils against corrosion. This ensures their durability and optimal performance.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

- Q: How are aluminum coils protected against corrosion during storage?

- Aluminum coils are protected against corrosion during storage through various methods and precautions. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing moisture and oxygen from coming into direct contact with the aluminum, which helps to prevent corrosion. Another method is the use of desiccants or moisture-absorbing materials. These materials are often placed inside the packaging or storage containers with the aluminum coils to absorb any moisture that may be present. By reducing the moisture content in the storage environment, the risk of corrosion is significantly minimized. In addition, proper storage conditions play a crucial role in protecting aluminum coils against corrosion. Storing the coils in a dry, well-ventilated area away from direct sunlight and other sources of moisture is essential. It is also important to ensure that the coils are stored off the ground and away from any chemicals or substances that could potentially cause corrosion. Regular inspections and maintenance are also necessary to prevent corrosion during storage. This includes checking for any signs of damage or wear on the protective coating and promptly addressing any issues that may arise. Additionally, maintaining a clean storage environment free from dust, dirt, and other contaminants will help in preserving the integrity of the protective coating and preventing corrosion. Overall, a combination of protective coatings, moisture-absorbing materials, proper storage conditions, and regular maintenance is essential for effectively protecting aluminum coils against corrosion during storage. These measures help to ensure that the coils remain in optimal condition and are ready for use when needed.

- Q: How can aluminium ingots be processed into aluminium coils (aluminium sheets)?

- This depends on what kind of ingot, and if it is small, it needs to be melted into a furnace, cast into a large plate, and then rolled on a mill

Send your message to us

S600 Aluminum Coil Price 5052 Temper H32 0.4mm 0.5mm 0.6mm Thick Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords