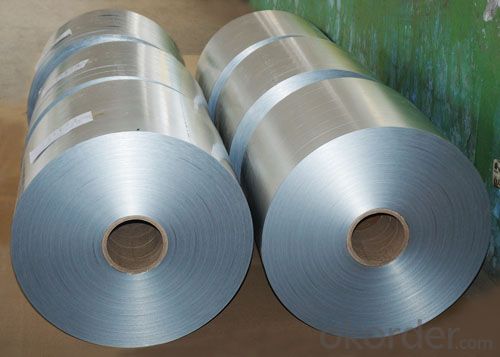

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: anyone know where to buy aluminium birdcage ?

- why would you want aluminium? pet stores don't sell them for a reason. The birds tend to chew and lick the wires of the cage and over time the aluminium can make them sick.

- Q: Are there any specific guidelines for handling and storing aluminum coils in warehouses?

- Specific guidelines exist for the handling and storage of aluminum coils in warehouses, with the aim of ensuring worker safety and maintaining coil integrity. Consider the following key points: 1. Equipment: When moving aluminum coils, it is crucial to utilize proper lifting equipment like cranes or forklifts with suitable attachments to prevent damage. Avoid dragging or dropping coils, as this may result in deformation or scratching. 2. Storage Location: Choose a well-ventilated, dry, and clean area for storing aluminum coils. The storage space should be away from direct sunlight, heat sources, and any chemicals that could react with aluminum. Maintaining consistent temperature and humidity levels is essential to prevent corrosion or other damage. 3. Stacking: Stack aluminum coils using appropriate dunnage material, such as wooden blocks or rubber mats, to prevent direct contact. This helps prevent scratches, dents, or other physical damage. Additionally, avoid excessive stacking height to prevent coil deformation or collapse. 4. Handling Precautions: Always wear proper personal protective equipment (PPE), including gloves and safety shoes, when handling aluminum coils. This safeguards against potential injuries from sharp edges or falling objects. 5. Labeling: Clearly label each coil with essential information such as weight, dimensions, alloy type, and any special handling instructions. This ensures proper identification and helps prevent mishandling or confusion. 6. Regular Inspections: Regularly inspect stored aluminum coils for signs of damage or corrosion. If any issues are identified, take immediate action to prevent further damage. 7. Security: Implement security measures to prevent unauthorized access to the storage area, protecting the coils from theft or vandalism. It is important to note that specific guidelines may vary based on the type and size of aluminum coils, as well as local regulations and industry standards. Consulting the manufacturer's instructions or seeking professional advice is recommended to ensure compliance with the appropriate handling and storage guidelines.

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion.

- Q: Is it advisable to use a hammer to open a stuck aluminum coil?

- <p>Using a hammer to break open an aluminum coil that is stuck closed is not recommended. Aluminum is a soft metal and can be easily damaged by blunt force. Instead, try using pliers or a screwdriver to gently pry open the coil. If the coil is rusted or stuck due to other reasons, applying a penetrating oil or lubricant might help loosen it without causing damage. Always prioritize safety and the preservation of the material when attempting to open or unstick objects.</p>

- Q: What is the average lifespan of aluminum coils?

- The lifespan of aluminum coils can differ based on a range of factors, including the quality of the aluminum, the environmental conditions they are subjected to, and the level of maintenance they receive. On average, aluminum coils typically endure for approximately 15 to 20 years. However, by implementing proper installation procedures, conducting regular cleaning, and performing maintenance tasks, the lifespan of aluminum coils can be extended further. It is vital to emphasize the significance of regular inspections and upkeep in order to enhance the longevity of aluminum coils and guarantee optimal performance.

- Q: How are aluminum coils different from steel coils?

- Aluminum coils differ from steel coils in terms of their material composition, weight, corrosion resistance, and conductivity. Aluminum coils are made of aluminum, while steel coils are made of steel. Aluminum is a lighter metal compared to steel, making aluminum coils lighter in weight. Moreover, aluminum coils have higher corrosion resistance due to the formation of a protective oxide layer on the surface. In terms of conductivity, aluminum coils have higher electrical conductivity compared to steel coils.

- Q: How are aluminum coils used in rainwater harvesting systems?

- Aluminum coils are commonly used in rainwater harvesting systems for their durability and efficient heat transfer properties. These coils are typically installed within the rainwater storage tanks and are connected to a heat exchanger system. The primary function of the aluminum coils in rainwater harvesting systems is to facilitate the heating or cooling of the stored rainwater, depending on the intended use. For instance, if the harvested rainwater is intended for domestic use, such as for showers or laundry, the aluminum coils can help heat the water to a desired temperature. On the other hand, if the harvested rainwater is intended for cooling purposes, such as air conditioning or industrial processes, the coils can help cool the water as well. The aluminum coils are designed in a way that maximizes the surface area exposed to the rainwater, allowing for efficient heat transfer. This means that the coils can rapidly absorb or release heat, depending on the needs of the system. The aluminum material used for these coils is preferred due to its high thermal conductivity, corrosion resistance, and lightweight properties. Additionally, the coils are also beneficial in preventing the growth of bacteria and algae within the rainwater storage tanks. Aluminum has natural antimicrobial properties that inhibit the growth of these organisms and ensure the harvested rainwater remains clean and safe for use. Overall, aluminum coils play a crucial role in rainwater harvesting systems by enhancing the usability of the collected rainwater through efficient heat transfer and maintenance of water quality.

- Q: Is it possible to create a baking pan using aluminum coil material?

- <p>Yes, you can use aluminum coil to make a baking pan. Aluminum is a popular material for baking pans due to its excellent heat conductivity, which allows for even heating. When creating a baking pan from aluminum coil, ensure that the coil is food-grade and that the edges are properly sealed to prevent any sharp edges. It's also important to consider the thickness of the aluminum, as a thicker gauge will distribute heat more evenly. Always follow safety guidelines and ensure that the aluminum coil is suitable for use in an oven.</p>

- Q: Can aluminum coils be used in high-pressure applications?

- No, aluminum coils are not typically used in high-pressure applications due to their lower strength and less resistance to deformation compared to other materials such as steel.

Send your message to us

1060 Temper H14 H24 0.3mm 0.5mm Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords