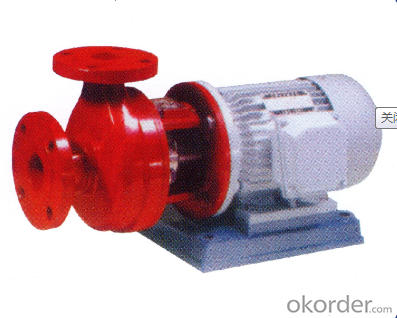

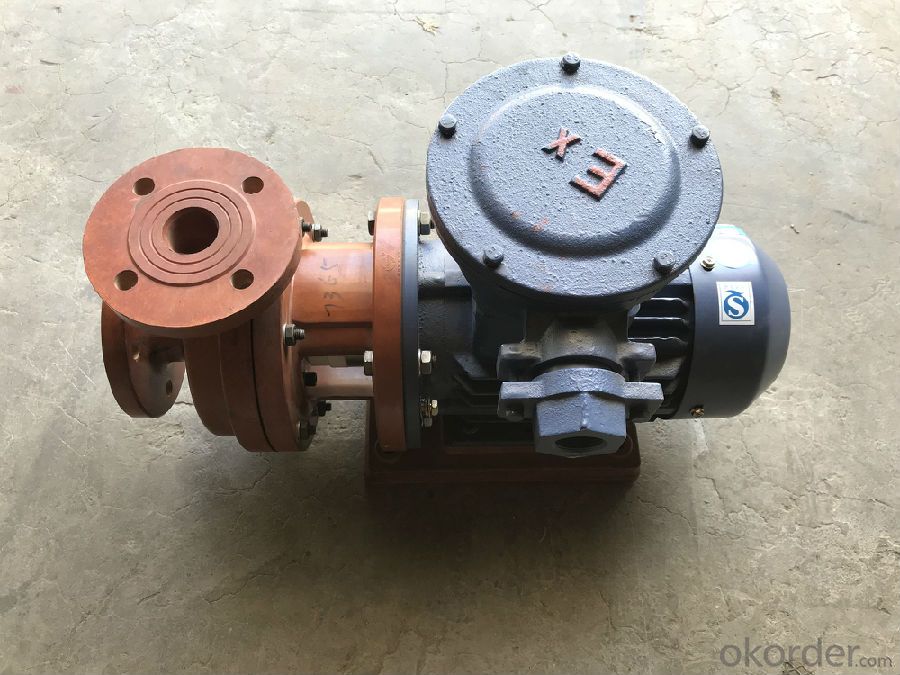

S Type anti-corrosive fiberglass centrifugal pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

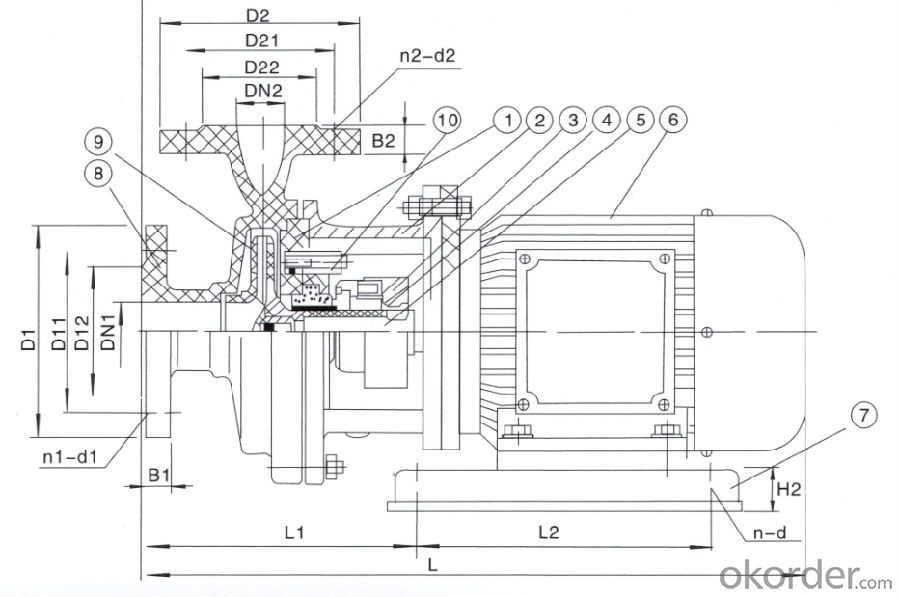

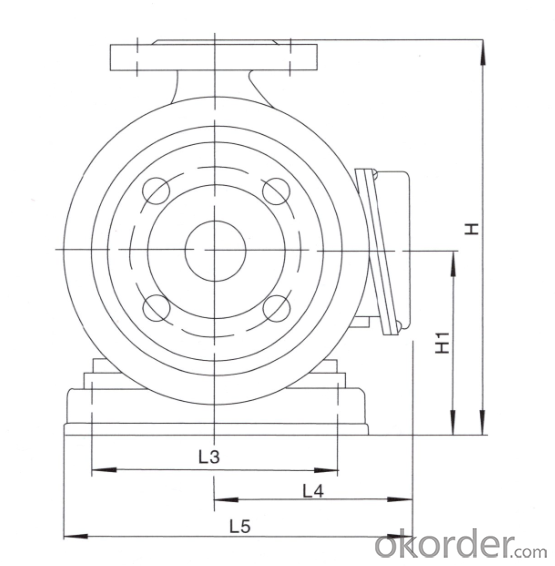

1. Structure of S Type anti-corrosive fiberglass centrifugal pump Description

The fiberglass centrifugal pump combines the motor and the pump components as a whole, relatively compact, easy to install with small power. It is mainly used in petrochemical, smelting, dyes, printing and dyeing, pesticides, pharmaceuticals, rare earth, fertilizer and other industries. The fiberglass centrifugal pump can transport slightly solid particles, not easy to crystallize. This pump is the essential ideal equipment for the corrosive media like some non-oxidation acid of not more than 100℃ (some acid temperature can reach 120℃).

2. Main Features of S Type anti-corrosive fiberglass centrifugal pump

•The products’ performance reaches the requirement of the trade standard JB/T8688-1998” plastic centrifugal pump”.

•Standardizing design, beautiful and dignified contour, reasonable and compact structure, universal parts and components, strong mutual changeableness.

•Optimum design of hydraulic model through Computer enables energy saving and high-efficiency

•Wetted components adopt phenolic fiberglass, through shaping under the conditions of high temperature and hot pressure, it has high strength and strong anti-corrosive performance.

•Axis sealing adopts Teflon mechanical sealing of outer-installing type with anti-strong corrosion and has extensively suitable scope with simple and reliable sealing.

•Single installation and convenient maintenance

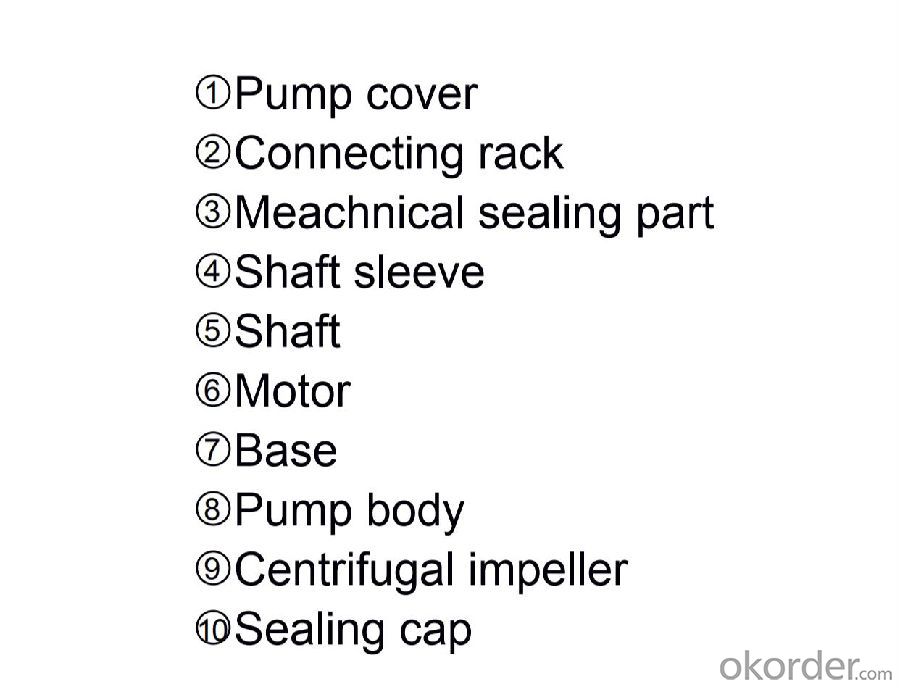

3. S Type anti-corrosive fiberglass centrifugal pump image

4. S Type anti-corrosive fiberglass centrifugal pump Specification\

Performance parameter Type | Q -Flow M3/h | H-Head M | Speed-n r/min | Efficiency % | NPSHr m | Motor capacity kW |

S25X25-12.5 | 3.2 | 12.5 | 2900 | 36 | 3 | 0.55 |

S40X32-20 | 6.3 | 20 | 42 | 3 | 1.1 | |

S40X32-32 | 6.3 | 32 | 35 | 3 | 2.2/3.0 | |

S50X40-20 | 12.5 | 20 | 53 | 3 | 2.2 | |

S50X32-32 | 12.5 | 32 | 48 | 3 | 4.0 | |

S65X50-20 | 25 | 20 | 62 | 3 | 3.0 | |

S65X50-32 | 25 | 32 | 57 | 3 | 5.5 | |

S80X65-32 | 50 | 32 | 65 | 4 | 7.5/11 | |

S100X80-50 | 100 | 50 | 68 | 5 | 22/30 |

5. Instructions

• The motor's revolving direction should be in conformity with the direction of pump's revolving direction pan. In order to protect pump from being damaged due to revolging in opposite direction, please first trial the revolving direction with hand to confrim the correct direction, then start the pump.

• Before starting, make the pump to be full of liquid; strictly forbid using concentrated acid.

• Don't allow pump idling without liquid, otherwise, the sealing end surface will be damaged due to dry friction.

- Q: Why does the centrifugal pump close the pressure to start?

- Therefore, the operation rules of multistage centrifugal pumps require that the inlet valve be opened before opening, and the outlet valve is closed. However, the export valve closed time can not be too long, because at this time the medium in the pump cycle, the medium temperature gradually increased, easy to cause mechanical seals, due to lack of lubrication friction and wear or damage.

- Q: Brief description of centrifugal pump on / off operation

- First, the preparation before the start(1) carefully check the inlet and outlet pipe line, valve, flange and pressure gauge joint of the pump, whether the installation is safe, comply with the requirements, whether the flow is correct, whether the anchor bolt and other connecting parts are loose or not.(2) add lubricating oil to the bearing case, and the oil level is 2/3 of the gauge of the bearing box.

- Q: What is the difference between centrifugal pump and positive displacement pump?

- Positive displacement pump is the volume pump, this type of pump is to rely on changes in volume to compress fluid work, including: diaphragm pumps, gear pumps, screw pumps, etc.;

- Q: How high can the pneumatic diaphragm pump be?

- If the pump material made of polypropylene (PP) material, corrosion resistance, good chemical resistance using PP material produced by pneumatic diaphragm pump can resist medium low cost, good generality, polypropylene material mainly is especially suitable for general acid-base liquid, using poly propylene made of plastic gas diaphragm pump can only withstand the highest temperature to 65 degrees, more than this number of polypropylene plastic deformation.

- Q: If the calculation of the required pump flow is 45, lift 110, and the actual pump flow 100, head 125, what will happen in operation? Can I use it properly?

- Centrifugal pumps are too big to measure.There is a reason why the centrifugal pump does not measure up:The pump inlet pipe blockage, leakage.The pump inlet pressure is too low.

- Q: Common failure treatment of piston pump

- Table 15 common troubles and treatment of hydraulic pumpsFault phenomenon, x09 cause analysis, x09 elimination method(1) the pump does not carry oil; the x091. pump does not turn x09 (1); the motor shaft does not rotate1) missed connection power supply2) electrical wiring and component failure, x09 check electrical and troubleshootx09x09 (2) motor heating trip

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Centrifugal pump, and is a very common method of centrifugal pump, flow with the head (or pressure) increases, off a small valve resistance increases, the pump head should be increased, then the flow decreased, whereas open valve flow increase

- Q: Why is the sewage pump device coupler?

- The automatic coupling device but the installation of GAK type submersible sewage pump, need lifting, people may not need to unscrew the screw water, the water pump can directly improve, after repairing down along the guide rail can realize sealing pump and pipeline, water pump and normal operation. Small sewage pump can be installed freely, large sewage pumps are generally equipped with automatic coupling device, automatic installation, installation and maintenance is very convenient.

- Q: Does the control cabinet of the fire control pump need to be related to the fire control room?

- The relationship is simple, the fire pump is pressurized water supply device, the control cabinet is the power supply for the fire pump, the regulator tank is to stabilize the pressure of the network management, reduce the pump frequently start device.

- Q: What does "dual purpose" of water pump mean? Please expert advice

- In order to ensure safe and continuous operation, three pumps usually need two units and run one standby.Precautions for using pumps1, if there is any small water pump failure, remember not to work. If the pump shaft packing end wear should be added in time, if you continue to use the water pump will leak. The direct effect of this is the increased energy consumption of the motor, which will damage the impeller.

Send your message to us

S Type anti-corrosive fiberglass centrifugal pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords