Rubber Conveyor Belt For Quarry And Mining Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rubber Conveyor Belt For Quarry And Mining Industry

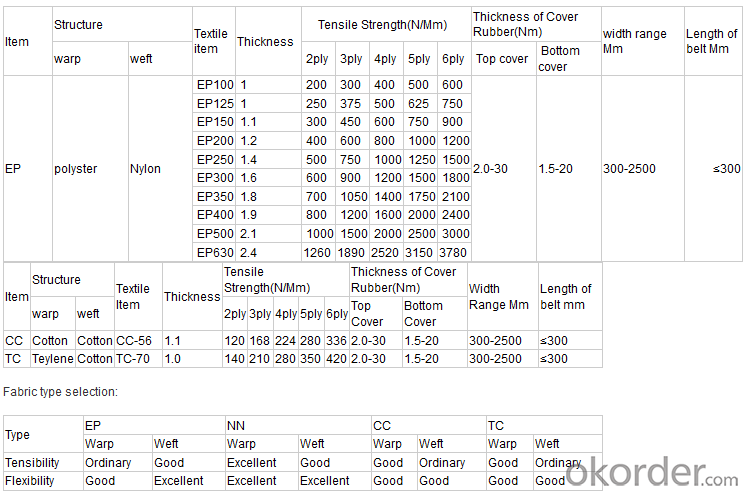

Description of Rubber Conveyor Belt

The product is made of Cotton/Nylon/EP canvas and finished through the process of assembling, vulcanizing etc, suitable for conveying materials that require a flame resistant and static conductive belts in power, chemical, light, metallurgical and grain processing industries, under the condition of flammable or explosive environment above coal mines.

The polyester conveying belt is also called EP conveying belt. Its framework material is the polyester canvas interwoven with meridian terylene and latitudinal polyamide fiber. It is characterized with excellent endurance, good water-resistance, no lowering of strength in humidity, mildewproof, and high load of initial models. It is applicable to convey materials in medium and long distance, with high-load, and at high speed.

Specification of Rubber Conveyor Belt

1) Fabric: Cotton, Nylon, Polyester

2) Width: 200mm-1800mm

3) Thickness: 4mm-20mm

4) T/S: 8Mpa-24Mpa

Pictures of Rubber Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: Which is better waterproof performance, neoprene or silica gel?

- High temperature silicone rubber is mainly used for making all kinds of silicone rubber products, while room temperature silicone rubber is mainly used as adhesives, potting materials or dies. The maximum amount of heat curing type, heat curing type and methyl silicone rubber (MQ), methyl vinyl silicone rubber (VMQ, dosage and product grades at most), methyl vinyl silicone rubber (PVMQ low temperature resistance and radiation resistance), there are other eyes of silicone rubber, fluorine rubber and so on.

- Q: Is work in rubber products harmful to health?

- In the manufacture of rubber products, the rubber itself is not toxic, but some agents are toxic, so most of the factories are now using intelligent small drug batching system, to avoid direct contact with the human body. In use, some contact with the human body rubber requirements are very high, from the choice of gum species (usually silicone rubber and PU), to the use of mixing agents, have strict requirements. If the general use, such as tires, seals and so on, and the body does not matter much.

- Q: What problems need to pay attention to when inflating the pipe?

- Rubber pipeline plugging bag should keep the inner pressure of the gasbag is uniform when inflated, inflated slowly rising inflation, observe the pressure gauge without change, such as pressure gauge shows rapid rise in inflation is too fast, the inflation rate should slow down, stop valve will tighten slightly, reduce the inlet velocity, or the speed is too fast, faster than pressure is likely to break into the rubber balloon. - Zhang

- Q: How to enhance the performance of water resistant silicone rubber products

- Steam can also reduce the performance of silicone rubber / silicone products, essentially the fracture of the backbone. The hydrolysis fracture reaction becomes apparent due to the increase of temperature and the presence of ionic reagents.

- Q: What is the lowest cost material for the synthesis of rubber?

- Poly propylene rubber is synthetic materials, he is a kind of synthetic rubber, with ethylene propylene copolymer rubber basic monomer, divided into two EPDM (EPM) and three EPDM (EPDM) two categories;

- Q: Does anyone know how to deal with the frosting of rubber and how to prevent it?

- To reduce blooming, mainly by adjusting the formula to achieve, such as reducing the amount of antioxidant in summer, storage time is short before vulcanization, if you can consider the use of paraffin wax, microcrystalline wax, if sulfur spray frost can consider changing into insoluble sulfur. Because I don't know your recipe, I adjust it according to the actual situation.

- Q: What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Generally used for metal strip trimming, that is, after the strip of metal strips with a fixed tool to remove burr or chamfer on both sides of the required radian,Scope of application: used in tableware, stationery, hardware, sheet metal and other special equipment industry.Main functions: grinding and polishing of double sides of roll beltApplicable materials: stainless steel, copper strip, aluminum belt and other metal coil.It has the advantages of rough grinding, fine grinding and polishing. It is suitable for grinding the bevel and straight edges of metal belts of different sizes and thicknesses, and is equipped with grinding wheels and spare grinding wheels. The grinding wheel has the advantages of long service life, regular forming rules and high efficiency.

- Q: For the application of common synthetic rubber, not too long or too difficult, want to do

- Natural rubber (NR) with rubber hydrocarbon (polyisoprene), containing a small amount of protein, carbohydrate, moisture, acid resin and inorganic salts. Flexibility, high tensile strength, tear resistance and excellent electrical insulation, good wear resistance and drought tolerance, processing of good, easy to other materials than in adhesive the performance of most synthetic rubber. The disadvantage is resistance to oxygen and ozone resistance, easy aging deterioration; oil resistance and solvent resistance is not good, the anti acid corrosion resistance low; heat resistance is not high. The temperature range of about - 60 DEG C ~ + 80 DEG C. Production of tires, rubber shoes, rubber hose, rubber belt wire and cable insulation and sheath as well as other common products. Especially suitable for manufacturing the torsional vibration eliminator, engine shock absorber, machine bearings, rubber metal diaphragm, suspension components, molded products.

- Q: Will rubber products fade?

- Rubber products will fade, is a rubber aging process, mainly due to external factors, temperature changes, the use of time, light, chemicals, external force and so on.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

Send your message to us

Rubber Conveyor Belt For Quarry And Mining Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords