Belt Conveyor For Coal ,Sand Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Belt Conveyor for coal ,sand making:

Type | Capacity(m3/h) | Diameter(mm) | Motor power (kw) |

B500 | 25-143 | 500 | 1.5-3 |

B650 | 40-243 | 630 | 1.5-4.5 |

B750 | 75-500 | 630 | 2.2-7.5 |

B1000 | 140-770 | 800 | 4-11 |

B1200 | 200-980 | 1000 | 5-22 |

Usage of Belt Conveyor for coal ,sand making

1,Working Temperature: -25°C~+40°C.

2,Material Temperature: not exceed 50°C. Further measures will be taken for the special requirements of anti-explosion, water proof, anti-corrosion, heat and cold resistance.

3, Material Bulk Density: 0.5~2.5t/m3

4, Belt Width: 500/650/800/1000/1200/1400/1600/1800/2000/2200/2400mm

5,Driving Device: electric motor with reducer, electric roller, etc.

Advantage

1.Economical and practical

2.Effective to use bulk material transporting over long distance

3.Effective for those places that require wide range of paths to travel

4.Durable, dependable and low cost operation

5.Belt width range is 400 mm to 1200 mm

6.Capacity is from 30 ton per hour to 480 ton per hour

Packing & Delivery

In nude, delivery time according the client's quantities.

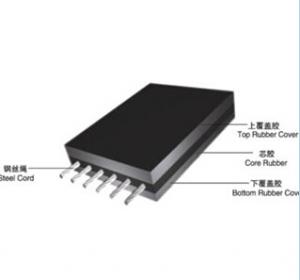

Picture of Belt Conveyor for coal ,sand making:

- Q: What is the working principle of the vibrating screen specially made of activated carbon?

- The sieving machine for granular activated carbon is driven by double vibration motor.

- Q: What are the characteristics of the vibrating screen for latex paints?

- Vibration screening filter / power rotary vibration sieve is vibration motor, vibration motor shaft is provided with a hammer (uneven weight), through the vibration rotational movement of the motor under unbalanced heavy hammer into a horizontal, vertical, three-dimensional motion is inclined three sport, rotary vibration sieve using vibration motor three-dimensional movement, spring and the vibrating body through the rotary vibration sieve to transfer to a vibrating screen 3D motion. By changing the phase angle of the upper and lower heavy weights of the vibrating motor to realize the movement track of the material on the screen surface, the purpose of sieving, removing impurity and filtering is achieved.

- Q: What is an efficient vibrating screen? Is it a high efficiency vibrating screen?

- The main engine realizes the full vibration under the support of the spring, so as to achieve the purpose of screening materials.

- Q: What are the common problems in the screening process of vibrating screen?

- Periodical overhaul of screening machineRegular overhaul of screening machines, including weekly inspection and monthly inspection.Before startup1. check the coarse and fine mesh without damageAre the 2. rings locked?After startup1. is there any abnormal sound?2. current is not stable3. there is no abnormal vibrationAfter use, clean up every time you use itRegularly check the coarse mesh, mesh, spring has no fatigue and damage. Are the parts of the body damaged by vibration?After the use of screening: clean up after each use

- Q: What are the factors that affect the screening efficiency of vibrating screens?

- Shape of grain and meshIn practice, most of the raw material is cylindrical Sieving (particle feed grade) or irregular particles, both circular and rectangular mesh, material particles contact state of the particles can pass through the mesh impact, through a hole diameter of 5 mm particles such as erect a 4 * 10 mm of the screen not horizontal. Therefore, whether or not particles pass by accident can only be studied by statistical means. Generally, the cylindrical particles and rectangular sieve holes have better performance, but for the irregular particles with small size difference in each direction, the passing performance of the circular hole is better.

- Q: What is the composition of a self balancing vibrating screen?

- The screen body part: either by transferring the hook on the rack, or by 4 vibration spring support.

- Q: What is a single axle vibrating screen? What's a biaxial vibrating screen?

- I just worked with them, not advertising, we have what to say, if you buy flour equipment, crusher, liming heavy industry is the boss, of course, choose to take care of all, mobile crushing station can do well! In short, choose a large company to buy equipment guaranteed!

- Q: What's the effect of a rattling shaker?

- 1, the structure is more compact, reducing the weight of the fuselage2, the product is more durable, nimble and convenient3, maintenance is simpler, parts easy to repair, Tesco4, high screening efficiency, at the same time with reciprocating and top shock vibration of two kinds of movement5, will not block the screen surface, fast material, screening thoroughly

- Q: Vibrating screen sand, then you can choose drum screen Mody? Why

- Roller screen is a kind of mineral processing equipment classification processing according to the material particle size, also known as the drum screen, because the layout is simple, is widely used in mining, building materials, traffic classification, energy and chemical industry. The classification and screening of medium and fine materials are often used to improve the quality of materials.

- Q: What is the screen frame of a linear vibrating screen?

- The less contaminated material is stainless steel

Send your message to us

Belt Conveyor For Coal ,Sand Making

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches