Roving Mat Fiberglass E-Glass Assembled Roving for Spray Up 180

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

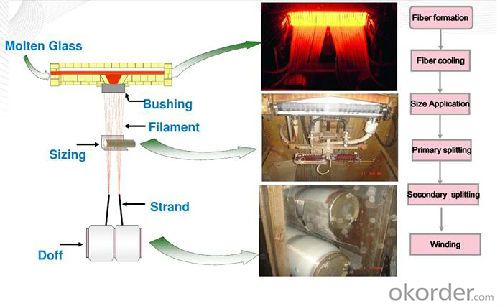

Introduction of E-Glass Fiber Spray Up Roving

10C Assembled roving for SPRAY UP process which is coated with high performance silane sizing, compatible with UP resin and Vinyl ester resin.

It is a versatile purpose spray up roving used to fabricate boats, bathtubs, water tanks, centrifugal casting pipes and panel etc.

Specification of E-Glass Fiber Spray Up Roving

PRODUCT NAME | E-GLASS FIBER ASSEMBLED ROVING for spray up 2400TEX | |

TEST ITEM | STANDARD NO. | STANDARD VALUE |

LINEAR DENSITY(TEX) | ISO 1889-1997 | 2400±120 |

STIFFNESS (MM) | iso 3375-1997 | 130±15 |

COMBUSTIBLE MATTER CONTENT (%) | iso 1887-1995 | 1.15±0.15 |

moisture CONTENT (%) | iso 3344-1997 | ≤0.10 |

Product Properties of E-Glass Fiber Spray Up Roving

1. Excellent process: easily chopped, good dispersion flay lying down and good anti-static performance.

2. Good wet-out: quick wet-out (resin), easily delete bubbles, well compatible with different resins.

3. Good composite performance: the composite is with properties of high mechanical strength and good surface effect etc.

Package of E-Glass Fiber Spray Up Roving

The roving will be packed on 20 pallets for a 20ft' container, or can be packed in small carton box.

The detailed package is listed as follows,

4 x 4 rolls/layer, 4 layer/pallet, 10 pallets

4 x 4 rolls/layer, 3 layer/pallet, 10 pallets.

Each layer is separated with paperboard. Each Pallet is supported by very strong paper tube at the four corners of pallet, packed in big carton, wrapped in a polythene stretched film.

.

Storage of E-Glass Fiber Spray Up Roving

Unless otherwise specified, fiberglass products should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65% respecitively. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, care should be taken to correctly and smoothly move the top pallet.

FAQ for E Glass Spray up Roving

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. What is the Production Lead Time?

5 *20GP each day.

- Q: Materials of european component

- Polymer:.5%, the low alkalinity sulphoaluminate cement, forming perfectly, do not use additives which contain calcium chloride based. 2. It is anti-permeability. As the Portland cement, it can be formed at one time. 4, China requires that when using the ordinary portland cement, the zirconia's content do not less than 16, including alkali resistant glass fiber roving, white portland cement..5%:. 3. plasticizer: The fibers used in GRC must be alkali resistant glass fiber, fiber, early strength agent, alkali resistant glass fiber mesh and retarder. As the requirement of Europe and America, the content of zirconium oxide in glass fiber should be no less than 16: The acrylic emulsion is usually the polymer: We can add some of the volcanic ash active material selectively, that is, acrylic copolymerized emulsion. 5: We can select soft rubber mold, made by high temperature resin which suit the hard outer mold: High efficiency water and anti freezing agents reducing agent can be selectively added. That is conducive to comprehensive performance, enhance the durability of GRC products commonly. The cement can be hardening at fast speed. Sulphoaluminate cement /additives, alkali resistant glass fiber chopped yarn is easy demoulding.

- Q: Knowledges of bamboo fiber.

- So it needs special equipment for processing, but because the bamboo fiber is very short, the most notable feature is the environmental protection and decontamination capability. At present, it is mainly used in textile products. There is an association of bamboo fiber, where phyllostachys pubescens (General requirements for three years) is soaked and peeled, almost like paper-making.

- Q: The safe operation of glass fiber twisting frame

- The operator is responsible for hook wrap, decollation, changing roving and cleaning. Doffer is responsible for cleaning. Both of them needs skills.

- Q: Medium alkali glass fiber cloth

- It is mainly used for large and medium sized non-metal container, equipment, pipe and shell.

- Q: What does 3240 belongs to?

- 240 epoxy resin is used to produce glass fiber cloth by high temperature and pressure. It features with heat resistance and moisture resistivity. It is often used as components and parts for electrical appliance and electron with its model is 3240. It has high mechanical properties under medium temperature. Heat resistant grade is F (155 degrees). It is suitable for machinery with stable electrical performance at high temperature.

- Q: The use of glass fiber cloth

- Reinforced material:

- Q: What equipment is needed for teating glass fiber twistless roving?

- Material tester.

- Q: Production process of glass fiber reinforced plastic

- Simple glass reinforced plastics are melted together again

- Q: waht about Plastic tray?

- Corrosion can not happen. Glass steel bridge use alkali glass fiber roving and its fabric as reinforcement material, welding or screwing connection, with the glass steel life for more than 50 years. Using unsaturated resin as matrix material, plastic colorant, glass steel bridge uses vinyl chloride (UPVC) resin as the main raw material. In fact, the material made for cable tray have something to do with the actual project. Glass steel belongs to high-quality composite materials, plus a proportion of the stabilizer, oil and other corrosive media, then it has antiseptic function and special filler. generally, plastic steel has 15-30years life. It is not very good for acid and salt, and it is not very ideal material for extrusion molding, corrosion protection and so on. Plastic tray has a price advantage, but the strength is not so good . After adding other mineral filler, long life, and then cured by heating, extruding into various sections of the hollow section processing, steel is steel profiles and the main chemical composition is PVC.

1. Manufacturer Overview

| Location | Chongqing, China |

| Year Established | 1971 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | North America, Eastern Europe, Southeast Asia, Mid East, Eastern Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Chongqing |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 2000,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Roving Mat Fiberglass E-Glass Assembled Roving for Spray Up 180

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 19600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords