High Silica Texturized Yarns with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000/month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

High silica texturized yarns could be used for a long period of time at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure.

2.Properties

No asbestos or ceramic,no harm to human boday

Braided to be packing

Heating insulation gasket

Braide to be heat resistance rope and sleevings.

3.Application

Being braided to be sleevings for thermal insulation

Sewing thread for high temperature fabrics

Lamp wick,electronic cigarettes atomizer

Wrap heating wire and heating component

High temperature gaskets

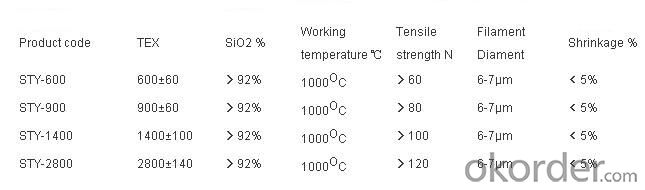

4.Specification

5.Package and Delivery

Packed with pallets and the products will be ready in 15-20 days after the order confirmed.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can you describe the production process of glass fiber and the production process?

- There are clay crucible method-the most primitive method; platinum substitute crucible, with the raw materials for the production of glass fiber glass and the poor quality of products and pool kiln method, with the process of high energy consumption, which is banned, where the the raw material is powder mixture with pyrophyllite. Platinum crucible method is widely used at present. Tank furnace method" is the most advanced technology and the main raw material is waste broken glass

- Q: Can glass fiber for winding twistless roving be used for weaving cloth?

- Yes, twistless roving are used as warp and weft directional material for twistless roving cloth.

- Q: Is glass steel a glass?

- Toughened glass is stronger than ordinary glass. One advantage is strong, and the two is broken, will not produce the tip of the debris, so that people are relatively safe.

- Q: Fiber has the difference between twist and twist

- The roving is divided into direct roving (also called direct yarn) and plied rovingDirect roving is defined as: parallel filaments and twisting and formed cluster body, no direct roving raw silk production process is relatively simple, products made of high strength glass steel products, can be directly applied to the winding and pultrusion process, can be directly used for cloth (i.e. roving fabric, commonly known as Plaid), therefore is widely used.

- Q: Introduction of inorganic glass fiber reinforced plastic air pipe

- Inorganic glass fiber reinforced plastic air pipe, according to the properties of the binding materials, can be divides into: Made of binding materials with glass fiber mesh cloth hydraulicity inorganic glass steel duct and made of cementitious materials and glass fiber mesh air hardening modified magnesium oxychloride cement duct with two types of modified magnesium oxychloride cement to the sulfate type. The pH value of the hardened material should be less than 8.8, and there is no alkalinity corrosion of the glass fiber. Inorganic glass steel duct should be used alkali-free, medium alkali or alkali resistant glass fiber mesh cloth, and are consistent with current national standard "glass fiber grid" JC561, "the alkali free glass fiber roving," JC/T281, "in the alkali glass fiber roving" JC/T576 regulations. The quality of magnesium oxychloride cement duct Magnesium Oxide should comply with the national standard "Magnesium Oxide" light burned magnesite products with WB/T1019-2002 regulations. Inorganic glass steel duct can divided into the overall common type (non insulation), integral insulation type (inner and outer surface of inorganic glass steel, middle insulating material) and combination type (by special adhesive, composite plate, flange, reinforcement angle etc) and the combination of insulation, its production parameters should comply with the provisions of the table 1, 2, 3. The longitudinal and transverse lap joint distance between adjacent layers of glass fiber grid cloth should be more than 300mm, and the distance of the same layer lap joint shall not be less than 500mm. Lap length should be greater than 50mm. The wind pipe surface thickness of the slurry flating glass fiber mesh cloth is appropriate. And the surface do not have dense pores and spillage.

- Q: The difference between glass fiber plain cloth and glass fiber woven roving.

- According to the weight and width, there are many models including 200 g, 400 g, 600 g and 800 g. The width of 900, 1000, 1270 and 1400 are commonly used. The width is from a few centimeters to 3 meters and the weight is from 60 to 800.

- Q: What is glass fiber extrusion

- Glass fiber extruding machine set can be used to produce different shapes of glass fiber reinforced plastics in different shapes, which can be formed by the oven traction machine oil pump station and so on.

- Q: How to deal with the folding force of glass fiber plastic coated yarn.

- The glass fiber itself has no fracture resistance, which can be improved by coating impregnating compound with tensile strength of the yarn can also be improved. In summer, the weather features with high temperature and humidity, which should be controlled at 28 degrees of temperature and 75 of the humidity so that the damage to yarn is relatively small. You may consider to improve the toughness of the coating material.

Send your message to us

High Silica Texturized Yarns with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000/month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords