Round Ductile Casting Iron Manhole Cover EN124 with OEM Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

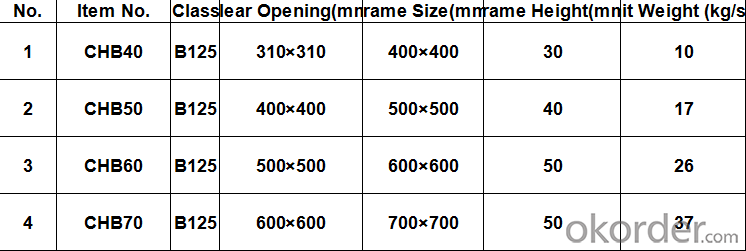

Sizes: 300 mm X 300 mm (11.81" X 11.81") clear opening to 1200 mm X 1200 mm (47.2" X 47.2") clear opening.

Load Rating: A15, B125, C250, D400, E600 and F900

Painting: Black Bitumen, Epoxy and other paint as per provided by customers.

Other Features: Hinging, Locking provision available, Leak proof and customized designed available.

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

FAQ

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

- Q: What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- Q: Why does the precision casting factory not usually make iron castings?

- Because it is too cheap, the design of materials is cast iron, generally do not have very high requirements.

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- According to different casting process and parts materials, each has relevant standards, can be found online;

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- For example Changchun FAW, under a casting, two casting and other casting plant, but there are more than half of all outsourcing in Tianjin Hebei Shandong purchase, many automobile enterprises to casting foundry.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

Round Ductile Casting Iron Manhole Cover EN124 with OEM Service

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches