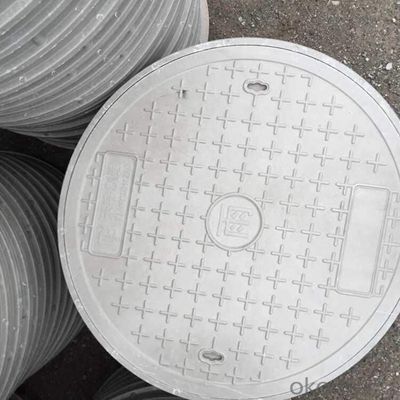

Double Ductile Iron Manhole Covers with OEM Service EN124

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

FAQ

About Sample

Q : Can I get free samples?

A: Yes, we can provide you the free sample, but you have to bear the delivery costs.

About Customer Logo

Q: Can I have my own logo on the product?

A: Yes, you can send your logo design to us and send us the authority letter. Then we can cast the logo on body.

- Q: Why does the precision casting factory not usually make iron castings?

- Jiangyin Lin Xing stainless steel (precision manufacturing) Co., Ltd. to provide professional precision casting

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: The casting sand is going on

- Dispersed sand inclusion is common on the surface and subcutaneous of steel castings, often concentrated on the outer surface of the upper box and the inner surface of the lower case, and a few of them are inside the cast steel parts.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: What should I pay attention to when designing a casting structure?

- The basic structure of unit 3 in the design of metal casting casting and its parameters are selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting casting casting; (2) the inner wall of the internal ribs and the thickness of a should be connected the outer wall thickness of 0.6 to 0.7, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage; (3) to prevent generating white grey cast iron, in addition to taking measures in the process, must make the wall thickness is not too thin (some information that cast fillet at the corner of the wall thickness of 15mm or more, with metal casting casting must be in the corner, for Aluminum Alloy, metal casting magnesium alloy castings shall not be less than 3 ~ 4m; (4) because of the metal type and the core that, for To facilitate the extraction of castings and casting out type, slope casting should be suitably large than sand casting metal casting, the general should be 30% ~ 50%, it should be pointed out that in addition to the height of the slope of casting size and alloy type, wall, is also related to the casting surface position, where the cooling and contraction of the metal type the surface of casting surface can be designed from the tendency of small inclination, while casting shrinkage tend to be pressed on the surface of metal casting type should be given greater inclination.

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

Send your message to us

Double Ductile Iron Manhole Covers with OEM Service EN124

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches