Rolled Stainless Steel Sheets - Hot Rolled Stainless Steel Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

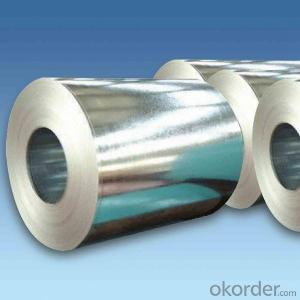

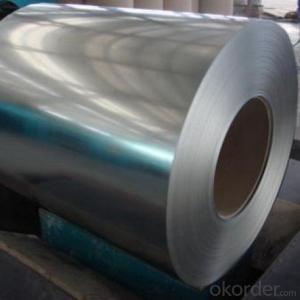

Detail picture for Stainless Steel Coils/Sheets

Application of Stainless Steel Coils

(1)Boiler heat exchanger,

(2)Chemical industries,

(3)Hardware fields,

(4)Construction material,

(5)Kitchen utensils,

(6)Building construction,

(7)Medical equipment,

(8)Chemical tank,

(9)Pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q:What are the common uses of stainless steel sheets in the food industry?

- Stainless steel sheets are widely used in the food industry due to their numerous beneficial properties. One common use of stainless steel sheets in the food industry is for food processing equipment. These sheets are used to fabricate machines such as mixing tanks, conveyors, and food processing tables. Stainless steel sheets are preferred for this purpose because they are resistant to corrosion, easy to clean, and do not react with food substances, ensuring the food's safety and hygiene. Another common use of stainless steel sheets in the food industry is for food storage and transportation. Stainless steel sheets are often used to manufacture containers, tanks, and barrels that are used to store and transport food products. The corrosion resistance of stainless steel ensures that the food is protected from contamination and spoilage during storage and transportation. Stainless steel sheets are also used for kitchen equipment in the food industry. Countertops, sinks, and cabinets are frequently made from stainless steel sheets due to their durability, heat resistance, and ease of cleaning. These qualities make stainless steel sheets ideal for use in food preparation areas where hygiene is of utmost importance. Furthermore, stainless steel sheets are utilized in the construction of food service equipment such as ovens, grills, and refrigerators. These sheets are crucial in maintaining the desired temperature and preventing the growth of bacteria, ensuring that the food served is safe and of high quality. In summary, stainless steel sheets are commonly used in the food industry for food processing equipment, food storage and transportation, kitchen equipment, and food service equipment. Their corrosion resistance, easy maintenance, and ability to uphold hygiene standards make them an ideal choice for various applications in the food industry.

- Q:Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

- Q:What is called anti fingerprint stainless steel sheet?

- The utility model improves the influence of fingerprints or oil pollution in the use of stainless steel products, and solves the difficult problem that the surface is easy to stick dirt and is difficult to clean. Meanwhile, the utility model avoids the defects of stainless steel surface damage, blackening or losing luster caused by the treatment of fingerprints or oil pollution by common chemical solvents. This is a new type of stainless steel surface processing technology, stainless steel material is not limited: such as 201#, 202#, 301#, 304#, 430#, 443# and so on can be processed!

- Q:Are stainless steel sheets resistant to nitric acid?

- Yes, stainless steel sheets are generally resistant to nitric acid due to the presence of chromium in their composition, which forms a passive oxide layer protecting the material from corrosion caused by nitric acid.

- Q:Can stainless steel sheets be used for fermentation tanks?

- Fermentation tanks can indeed utilize stainless steel sheets. The reason behind this preference lies in stainless steel's durability, resistance to corrosion, and capability to maintain the desired temperature. Its non-reactive nature guarantees the purity and quality of the product by preventing any interaction with the fermenting substances. Furthermore, stainless steel's easy-clean and sanitize properties are vital in ensuring hygienic conditions throughout the fermentation process. On top of all that, stainless steel sheets can be shaped and sized according to specific requirements for fermentation tanks. Consequently, stainless steel sheets are a dependable and popular choice in multiple industries, including brewing, winemaking, and food processing.

- Q:Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is a popular choice for water tanks due to its corrosion-resistant properties. It is highly resistant to rust and can withstand exposure to water and moisture without deteriorating. Stainless steel is also hygienic, as it does not react with water or leach any harmful substances into it. Additionally, stainless steel tanks are durable and long-lasting, making them a reliable option for storing water. Overall, stainless steel sheets are a suitable material for constructing water tanks, providing a safe and reliable storage solution for water.

- Q:Who knows the production process of stainless steel plate?

- Sanitary conditions are important for many industries, such as food processing, catering, brewing and chemical processes. In these applications, the surface must be cleaned daily and chemical cleaning agents are often used.Stainless steel is the best material in this area, in public places, the surface of the stainless steel is often scribbles, but an important characteristic is it can be washed off, this is a remarkable characteristic of stainless steel is better than aluminum. The surface of aluminum tends to leave traces that are often difficult to remove. When cleaning the stainless steel surface, it should be cleaned along the lines of stainless steel, because some of the surface finishing lines are unidirectional.Stainless steel most suitable for hospital or other health conditions of critical field, such as: food processing, food, brewing and chemical industry, this is not only because it is easy to clean every day, sometimes the use of chemical cleaning agents, but also because it is not easy to breed bacteria. Tests show that stainless steel has the same properties in this field as glass and ceramics.

- Q:What's the difference between galvanized steel and stainless steel?

- Galvanized steel sheet is to prevent the corrosion of steel plate surface, and prolong its service life, the surface of the steel plate is coated with a layer of metal zinc, this kind of zinc coated steel sheet is called galvanized sheet.

- Q:Are stainless steel sheets resistant to high-pressure environments?

- Stainless steel sheets exhibit remarkable resistance to high-pressure environments. This material boasts robustness and durability, enabling it to endure the immense force exerted by diverse industrial operations, including hydraulic systems, chemical processing plants, and oil and gas pipelines. Its outstanding tensile strength and capacity to maintain structural integrity even in the face of extreme pressure make it highly esteemed. Moreover, stainless steel also possesses corrosion resistance, further bolstering its suitability for high-pressure settings where exposure to moisture or chemicals is prevalent. Consequently, stainless steel sheets are extensively employed in industries that demand materials capable of withstanding high-pressure circumstances due to their exceptional strength and resistance attributes.

- Q:Can stainless steel sheets be used for chemical reactors?

- Indeed, chemical reactors can indeed utilize stainless steel sheets. The utilization of stainless steel in chemical reactors is quite popular due to its remarkable resistance to corrosion. Its ability to resist chemical reactions with various substances is commendable, thus rendering it suitable for handling corrosive chemicals or environments. Moreover, stainless steel sheets are renowned for their durability, exceptional strength, and capacity to endure high temperatures. Hence, they are ideal for deployment in chemical reactors that may operate under extreme conditions. Furthermore, stainless steel is effortlessly maintainable and easy to clean, which is a pivotal factor in ensuring the purity and integrity of the reaction process. In conclusion, stainless steel sheets are widely employed in the construction of chemical reactors and are widely recognized as a trustworthy and efficient choice of material for this purpose.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rolled Stainless Steel Sheets - Hot Rolled Stainless Steel Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords